Installing An Emergency Stop On A Metal Lathe For Safety

Metal Lathe Emergency Stop Install

Imagine a fun day at the workshop, turning a piece of metal. Suddenly, the lathe spins out of control. What would you do? A metal lathe emergency stop can save the day! Installing this button is easier than it sounds. It gives you power to stop the machine instantly. Safety first, right? With a quick push, you keep everyone safe. This simple tool is your key to worry-free work.Understanding the Importance of an Emergency Stop

Safety benefits in industrial settings. Compliance with industry safety standards.Emergency stops are crucial for safety in factories. They keep people safe if something goes wrong with machines. Most factories have rules about safety. Workers and companies must follow these rules to prevent accidents. Using emergency stops can stop the machine quickly to avoid danger. Did you know they can save many lives? The process is simple but very effective. It’s like a hero button but on a machine! Remember, safety first!

Why are emergency stops important on metal lathes?

Emergency stops are vital for metal lathes because they can prevent accidents. If a lathe spins out of control, the stop button can quickly halt it. This feature helps ensure that workers stay safe during operation.

Types of Emergency Stop Mechanisms

Pushbutton stops. Mushroom head buttons and their advantages.Emergencies on a metal lathe might demand a quick halt. The go-to heroes are pushbutton stops. They’re like the superheroes—easy to spot and smack! But wait, there’s a twist! Meet the mushroom head buttons, they look fun and are easy to press, even with clumsy gloves. These buttons are large, round, and easy to reach. Their design ensures quick reactions, minimizing accidents.

| Type | Features | Advantages |

|---|---|---|

| Pushbutton Stop | Easy to Press, Immediate Response | Quick Safety Activation |

| Mushroom Head Button | Large, Round, Glove Friendly | Highly Visible, Easy to Use in Panic |

In truth, emergency stops turn potential chaos into control. They are essential in ensuring the lathe doesn’t work against you. Always Choose a button that suits your work style. After all, even machines deserve a pause when needed!

Necessary Tools and Materials

List of tools required for installation. Recommended emergency stop kits for metal lathes.Installing an emergency stop on a metal lathe? You’ll need the right tools, or it’ll be like baking without a recipe—chaos! Here’s a handy checklist:

| Tools | Purpose |

|---|---|

| Screwdriver | For fastening and unfastening screws. |

| Wrench | To give nuts and bolts a snug fit. |

| Wire Stripper | For proper wire connection. |

| Drill | Making holes for mounting the stop button. |

A good emergency stop kit will stop your lathe faster than you can say “oops!” Popular kits usually come with instructions and all necessary parts. Remember to always choose safety over speed, because a lathe that won’t stop is like a runaway train. You don’t want to be calling for help mid-spin!

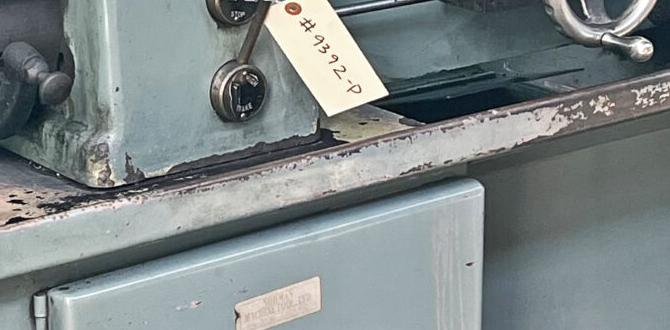

Preparing Your Metal Lathe for Installation

Ensuring the machine is turned off and unplugged. Identifying optimal locations for emergency stop placement.Before you start, ensure your metal lathe is safe. First, make sure it is turned off and unplugged. This keeps everyone safe. Next, find the best spot to install the emergency stop. Look for places that are easy to reach. Think about spots like:

- Close to the main power switch

- Near the operator’s standing area

Why is unplugging the metal lathe important?

Unplugging the lathe stops it from starting by accident. It is the safest way to prepare the machine.

—Ensuring safety and effective setup involves critical steps. Remember: a safe machine is a smart machine.

Step-by-Step Installation Process

Mounting the emergency stop button on the lathe. Wiring the emergency stop into the lathe’s electrical system.Imagine installing an emergency stop on a metal lathe. Let’s dive into this process. First, find a spot on the lathe to mount the button. Ensure it’s easy to reach. Next, connect the button to the lathe’s electrical system. This stops the machine when pressed. Always turn off the power before starting the work. For safety, ensure all connections are secure and test the button when you finish.

Why is an emergency stop important on a lathe?

An emergency stop is crucial for safety. It stops the lathe quickly during problems. Workers can avoid injuries by using it. This feature is like a brake in a car.

Steps to ensure proper safety:

- Regularly check the button function.

- Train everyone to use it right.

- Keep the button free from obstructions.

This setup improves safety and gives peace of mind. Like adding extra protection, it ensures you are always ready if something goes wrong. It’s like a safety net for you and your work.

Testing the Emergency Stop Functionality

Initial functionality tests to ensure proper operation. Troubleshooting common issues during testing.So, you’ve just set up the emergency stop on your metal lathe, and now it’s action time! First, give it a spin—no, not the lathe, your finger! Press that emergency button to see if it stops the machine quicker than you can say “Oops!” If it doesn’t, check the wiring—sometimes those wires can play hide and seek.

A common hiccup might be loose connections, so tighten them up like you’re screwing in a light bulb. Here’s a quick troubleshooting table for you:

| Issue | Possible Solution |

|---|---|

| Button not working | Check connections |

| Lathe keeps spinning | Inspect button contact |

If it still acts up, don’t panic! It’s not a ghost; it’s probably a wiring gremlin. Giving the correct functionality is like showing off perfectly styled hair for a salon owner—it makes all the difference! Follow these checks and you might just become the lathe whisperer in no time.

Maintaining and Inspecting the Emergency Stop

Regular maintenance schedule for optimal operation. Signs that the emergency stop needs repair or replacement.Keeping the emergency stop on your metal lathe in tip-top shape is like giving your car a regular oil change. It keeps things running smoothly! A steady maintenance schedule helps avoid surprises. Check the button for dirt or signs of wear every month. If it sticks or feels wonky, it might need a fix. Look for frayed wires or loose parts that scream, “Help me!” Remember, a healthy lathe makes happy projects.

| Inspection Frequency | What to Look For |

|---|---|

| Monthly | Dirt, wear and tear on buttons |

| Quarterly | Loose wires or connections |

| Annually | Overall system test |

Does the stop button work like a charm when pressed? If not, it may need love or a replacement. Signs it is time to swap it out include a dull or faded button and unresponsiveness. Testing it regularly saves you from unexpected hiccups. As they say, an ounce of prevention is worth a pound of fix-it time!

Frequently Asked Questions about Emergency Stops

Addressing common concerns and misconceptions. Best practices for ongoing safety and compliance.It’s common for folks to wonder about emergency stops. One big question is, “How often should you check if it works?” Think of it like brushing your teeth – regular checks keep you safe! Aim for a monthly check to ensure everything is working. Another curiosity is, “What happens if it’s pressed by accident?” Fear not! Using it correctly is vital, but mistakes can be corrected.

Best practice is to keep the area clear and train everyone. Remember, safety comes first, even if it feels like you’re a superhero stopping a runaway train! Stay alert and check your stops like you’d check your favorite video game controls – often and with care!

| FAQ | Answer |

|---|---|

| How often to test emergency stops? | Every month |

| Accidental press? | Resets easily |

Conclusion

Installing an emergency stop on a metal lathe is crucial for safety. It helps you quickly halt the machine if needed. Make sure it’s easily accessible and functional. By doing this, you can prevent accidents and protect yourself. We recommend learning more about machine safety and emergency procedures to stay informed and safe in your workspace.FAQs

What Are The Essential Components Required For Installing An Emergency Stop System On A Metal Lathe?To install an emergency stop system on a metal lathe, you need a few key parts. First, get a big red emergency stop button that is easy to see. Next, you need wires to connect the button to the machine. You also need a relay, which helps turn off the lathe quickly. Finally, make sure you read the metal lathe’s manual to understand how everything fits together.

How Do You Properly Wire The Emergency Stop Button To Ensure It Interrupts Power To The Lathe Effectively?To wire the emergency stop button correctly, start by turning off the lathe. You need to connect the button to the power supply. Use two wires to connect the button to the machine. When you push the button, it should cut off the power. Always check your connections to make sure they are secure.

What Safety Standards Should Be Considered When Designing And Installing An Emergency Stop Mechanism On Industrial Machinery Like Metal Lathes?When we design and install an emergency stop for machines like metal lathes, we need to follow some important safety rules. First, the stop button should be easy to reach and big enough to press quickly. We should also make sure the button works properly every time you press it. It’s important to test the emergency stop often to keep everyone safe. Lastly, we can use bright colors for the button to make it easy to find.

How Can You Test The Functionality Of The Emergency Stop System To Ensure It Works Correctly During A Critical Situation?To test the emergency stop system, you can follow a simple plan. First, make sure everyone knows where the stop button is. Then, press the button to see if it works. If it stops everything as it should, that’s great! You should practice this regularly to make sure it will work in a real emergency.

What Are The Common Mistakes To Avoid When Installing An Emergency Stop Button On A Metal Lathe?When installing an emergency stop button on a metal lathe, avoid a few common mistakes. First, don’t place the button too far from where you work. You need to reach it quickly in an emergency. Second, check that the button is wired correctly. If it’s not, it won’t work when you need it. Lastly, make sure everyone who uses the lathe knows where it is and how to use it.