Have you ever looked at a metal lathe and wondered how it works? It’s a fascinating tool, isn’t it? One of the essential parts of this machine is the tailstock. If it’s not working well, it can cause big problems.

But don’t worry! Rebuilding the tailstock is easier than you might think. Imagine having a smooth-running lathe that helps you create amazing projects. Isn’t that a great idea?

In this article, we’ll explore the metal lathe tailstock rebuild steps. This guide will help you learn how to fix or improve your machine. You’ll discover the tools you need and the steps to follow. By the end, you’ll feel like a true craftsman!

Did you know a well-maintained tailstock can extend the life of your lathe? It’s true! Let’s dive in and learn how to make your lathe work better than ever.

Metal Lathe Tailstock Rebuild Steps: A Comprehensive Guide

Metal Lathe Tailstock Rebuild Steps

Rebuilding a metal lathe tailstock is a rewarding project. Start by gathering tools and cleaning the parts. Remove the tailstock carefully; it’s vital to note how everything fits together. Next, inspect and repair any worn parts. Lubricate moving parts for smooth operation. Have you ever struggled with a misaligned tailstock? Proper alignment can improve your work’s accuracy! Finally, reassemble the tailstock, ensuring everything is tight. With patience, your lathe will perform like new!Understanding the Tailstock Assembly

Description of the tailstock and its function in metal lathes. Common types of tailstocks used in metalworking.The tailstock is an important part of a metal lathe. It holds tools and supports the workpiece. This helps create smooth and precise cuts. Without the tailstock, the work would be unstable. There are two common types of tailstocks:

- Fixed tailstock: Does not move. It stays in one position.

- Sliding tailstock: Can slide for different lengths. It can be adjusted based on the workpiece size.

Understanding the tailstock helps when rebuilding and using a lathe effectively.

What is the function of the tailstock in metal lathes?

The tailstock supports tools and materials while the machine operates, ensuring accuracy. It also allows for various adjustments, making it essential in metalworking.

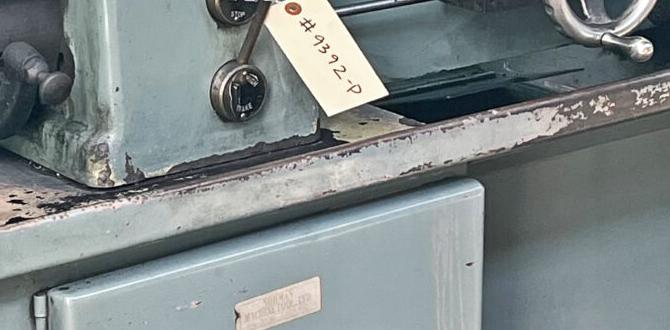

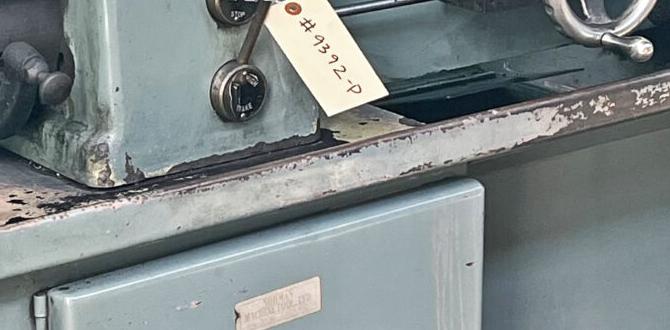

Assessing Tailstock Condition

Signs that indicate a tailstock needs rebuilding. Tools and equipment needed for assessment.Checking the tailstock helps ensure your metal lathe works well. Look for signs like uneven cuts, loose parts, or rust. These mean the tailstock might need fixing. Use simple tools like a ruler, level, and wrench to help with your check.

- Ruler to measure accuracy

- Level for checking straightness

- Wrench for tightening loose parts

Remember, taking these steps can save time and get the best results from your lathe!

What are signs a tailstock needs rebuilding?

Signs include uneven cuts, noise, and rust. If the tailstock wobbles, it’s time to check it.

Disassembling the Tailstock

Stepbystep guide to safely disassemble the tailstock. Tips for organizing parts for easier reassembly.Start by unplugging your metal lathe. Take off the tailstock carefully. Use a wrench to loosen the screws. Keep the screws in one container to avoid losing them. Label each part as you remove it. This helps during reassembly. Take pictures if needed. Remember to handle each part gently to avoid damage. Organizing parts can save time. A tidy workspace makes it easier. Following these steps can guide you smoothly through the disassembly process.

How do I organize parts for reassembly?

Use small bins or containers to organize parts. Label each container with the part’s name. Take notes on where each part goes. This will help you remember. Consider using a tray to hold screws and small items. Clear and neat storage makes reassembly simpler.

Cleaning and Inspecting Components

Recommended cleaning methods for tailstock parts. Critical areas to inspect for wear and damage.Start by cleaning all tailstock parts. Use a soft cloth and mild soap. You can also use a brush for tight spaces. It helps remove dirt without scratching. Next, look for critical areas. Check for wear or damage in:

- Screws for tightness

- Guideways for rough spots

- Bearings for smooth movement

- Locking mechanisms for proper function

A clean and inspected tailstock ensures better performance. Regular checks can prevent bigger problems down the line.

What should you check for wear in a tailstock?

Look for screws, guideways, bearings, and locking mechanisms. Ensure all parts work smoothly. Signs of wear can lead to issues.

Replacing Worn Parts

Identifying common parts that require replacement. Sourcing highquality replacement components.It’s important to check parts that wear out over time. Common parts to replace include bearings, lead screws, and gears. Sourcing high-quality replacements ensures your lathe works better and lasts longer. You can find these parts at local shops or online. Look for trusted brands to guarantee quality. This helps avoid future issues and keeps your metal lathe running smoothly.

What parts should I replace on my tailstock?

Key parts to replace include:

- Bearings

- Lead screws

- Gears

- Hand wheels

- Locating pins

Where can I find quality replacement parts?

Try local hardware stores or major online retailers for high-quality parts.

Reassembling the Tailstock

Detailed instructions for reassembling the tailstock. Ensuring proper alignment and function during reassembly.To put the tailstock back together, start by cleaning all parts. This helps ensure smooth operation. Align each piece properly. You want everything to fit snugly without forcing it. Next, use the right tools to secure all screws. Check if the tailstock moves easily. It should slide without wobbling. If it doesn’t, adjustments may be needed. Double-check alignment to prevent issues later on. Your efforts here will pay off in smooth cuts!

What should I ensure when reassembling the tailstock?

Ensure proper alignment and a secure fit to avoid problems later, like wobbling or difficulty sliding.

Key steps to ensure proper function:

- Clean all parts thoroughly.

- Align each piece snugly.

- Use correct tools to tighten screws.

- Test the movement after reassembly.

Testing Functionality After Rebuild

Procedures for testing the rebuilt tailstock. Troubleshooting common issues that may arise.After giving your tailstock a makeover, it’s time to see if it can still hit the mark! Start by checking if the tailstock moves smoothly along the bed. You don’t want it to waddle like a duck! Next, test the locking mechanism. If it clicks tighter than your grandma’s hugs, you’re golden! If things go awry, a crooked screw or misalignment could be the culprit. Here’s a handy table to help you troubleshoot:

| Issue | Solution |

|---|---|

| Stuck Movement | Check for debris or misalignment |

| Loose Locking | Tighten screws and inspect mechanisms |

| Inconsistent Pressure | Examine the feed screw for wear |

If your tailstock is behaving like a champ, congratulations! You’ve successfully completed the rebuild. If not, don’t worry! With some TLC and a little tinkering, you can have it running smoothly in no time. Happy turning!

Maintenance Tips for Longevity

Regular maintenance practices to keep the tailstock in optimal condition. Recommended lubrication and care for different tailstock components.To keep your tailstock happy and humming, regular care is key. Check its parts often for wear and tear. Dust bunnies love to hide in small spaces, so give it a good cleaning now and then. Use the right lubrication for each part, like using peanut butter for a sandwich—it just makes everything work better! Here’s a quick look at what to lubricate:

| Component | Recommended Lubrication |

|---|---|

| Guideways | Way oil |

| Screws | Grease |

| Bearings | Light oil |

Remember, a happy lathe means better work! So check, clean, and oil those parts regularly, just like you’d water a plant—only much less messy!

Conclusion

In summary, rebuilding a metal lathe tailstock involves cleaning, replacing worn parts, and proper alignment. You should gather the right tools and follow each step carefully. Remember, practice makes perfect. Don’t hesitate to dive into more resources on this topic for better results. With patience, you’ll enjoy smooth operations with your lathe! Keep exploring and learning.FAQs

Sure! Here Are Five Related Questions About Metal Lathe Tailstock Rebuild Steps:Sure! Here are some answers about rebuilding a metal lathe tailstock. First, you need to remove the tailstock from the lathe. Then, clean all the parts with a cloth. Next, check if any parts are broken and need replacement. After that, put everything back together and test it to make sure it works well.

Sure! I can help with that. Just let me know what question you have, and I’ll give you a simple answer.

What Are The Common Signs That Indicate A Metal Lathe Tailstock Needs To Be Rebuilt?You might notice some signs that mean the tailstock needs fixing. If it wobbles when you use it, that’s a problem. You may also see that it doesn’t hold your tools tightly, making them slip. If it makes strange noises, it might need repair. Lastly, if it feels hard to move, it’s time to rebuild it.

What Tools And Materials Are Required For A Thorough Tailstock Rebuild On A Metal Lathe?To rebuild a tailstock on a metal lathe, you need some tools and materials. First, get a wrench to loosen and tighten parts. You’ll also want screwdrivers for removing the screws. Don’t forget cleaning supplies like a cloth and oil to make everything smooth. Finally, have replacement parts ready, like new screws or a new spring, if needed.

Can You Outline The Step-By-Step Process For Disassembling A Tailstock For Rebuilding?To take apart a tailstock, first, unplug the machine for safety. Then, find the screws holding the tailstock in place and unscrew them. Carefully lift the tailstock off the machine. Next, look for any pins or parts that might be holding it together and remove them gently. Finally, keep all the pieces in a safe place so you can use them when you rebuild it.

What Are The Best Practices For Inspecting And Replacing Worn Components During A Tailstock Rebuild?When rebuilding a tailstock, first, check all the parts carefully. Look for cracks, rust, or any damage. If you find worn components, it’s best to replace them with new ones. Make sure new parts fit well and work nicely with the tailstock. Finally, clean everything before putting it back together to ensure smooth operation.

How Can Alignment Be Accurately Checked And Adjusted After Completing A Tailstock Rebuild On A Metal Lathe?To check if the tailstock is aligned, use a test bar. Place the test bar in the tailstock and turn it on. Then, measure the bar’s ends with a ruler or caliper. If they don’t match, you need to adjust the tailstock screws. Keep adjusting until both ends are the same.