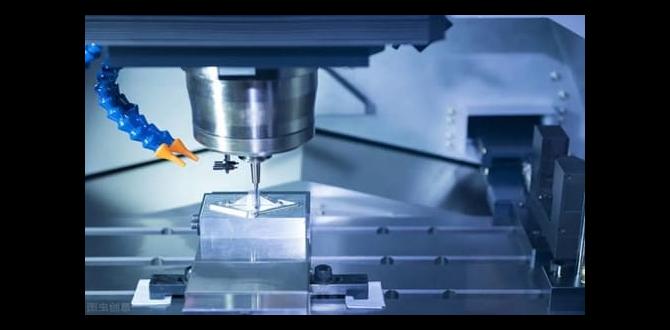

Have you ever wondered how complex shapes are made from metal? One key technique is the milling cutter groove machining strategy. This method shapes metal pieces into precise designs. Imagine creating a perfect groove in a block of steel. Sounds cool, right?

Using the right tools, like milling cutters, makes all the difference. These cutters carve out grooves with amazing accuracy. It’s like drawing with a pencil, but on a much larger scale. Each groove serves a purpose, from fitting pieces together to adding strength.

But why is groove machining so important? Well, every car, airplane, and machine uses parts shaped this way. Without it, many objects we rely on wouldn’t function. Learning about this strategy opens up a world of exciting possibilities.

Let’s dive into the fascinating world of milling cutter groove machining. You might find yourself inspired to create or invent something new!

Milling Cutter Groove Machining Strategy: Techniques And Tips

Milling Cutter Groove Machining Strategy

Milling cutter groove machining is essential in various industries. This strategy optimizes cutting performance and tool life. It allows for precise creation of grooves, enhancing design flexibility. Have you ever wondered how grooves in metal or wood are perfectly shaped? By using the right cutter geometry and parameters, you achieve smooth finishes and accurate depths. This not only improves efficiency but also reduces future costs. Discovering tricks in this machining strategy can lead to amazing results!Understanding Milling Cutters

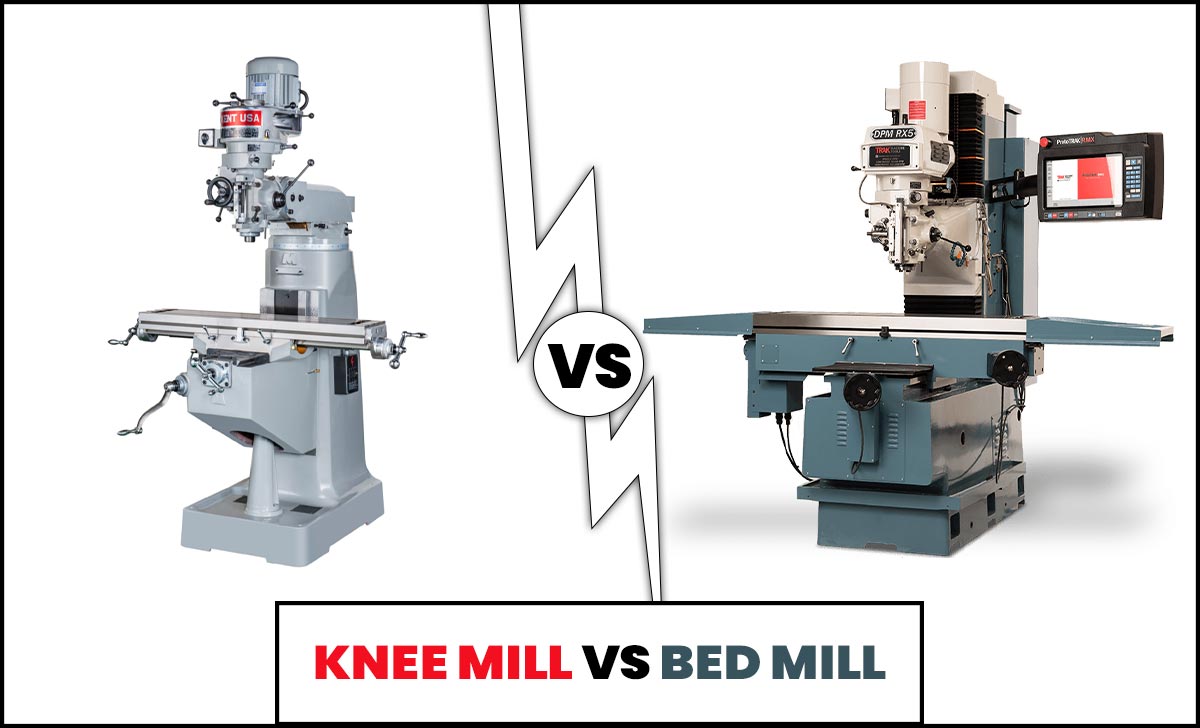

Definition and function of milling cutters. Types of milling cutters used in groove machining.Milling cutters are special tools used in machines to shape materials like metal and wood. They work like a chef’s knife, slicing through material to create grooves and shapes. There are different types of milling cutters for groove machining, like end mills and slab mills. Each type has a unique purpose, often leaving you saying, “Why did I not know this sooner?” Here’s a simple table to help you understand:

| Type of Milling Cutter | Function |

|---|---|

| End Mill | Perfect for creating grooves and contours. |

| Slab Mill | Great for flat surfaces and thick cuts. |

| Ball Nose Mill | Used for curved shapes and intricate designs. |

These cutters are essential in groove machining, making them the unsung heroes of the shop floor.

Importance of Groove Machining

Applications and industries utilizing groove machining. Benefits of effectively designed grooves.Groove machining plays a vital role across various industries, from automotive to aerospace. These grooves can be found in everything from car parts to energy-efficient engines. Designed grooves improve functions like fluid flow and assembly accuracy. With well-made grooves, parts fit perfectly and work better. They save time and reduce waste. So, a well-placed groove might be the difference between a smooth operation and a chaotic disaster, like trying to fit a square peg in a round hole!

| Industry | Applications |

|---|---|

| Automotive | Engine components |

| Aerospace | Fuel systems |

| Construction | Pipe fittings |

Factors Influencing Groove Machining Strategies

Material selection and its impact on machining. Tool geometry and parameters for optimal performance.Groove machining strategies depend on several important factors. First, material selection can make or break your project. Soft metals like aluminum are easier to machine than hard ones like steel. Second, the tool geometry matters too! A tool with the right angle cuts better and lasts longer. Also, using the right parameters like speed and feed rate can boost performance. Remember, the right tool may save you from throwing a tantrum later!

| Material Type | Machinability Rating |

|---|---|

| Aluminum | Excellent |

| Steel | Moderate |

| Titanium | Poor |

Common Groove Machining Techniques

Face milling vs slot milling. Downcut vs upcut milling techniques.Milling techniques are crucial in making accurate grooves. Two common methods are face milling and slot milling. Face milling creates flat surfaces, which is useful for larger areas. Slot milling makes narrow channels or slots, perfect for fitting pieces together. When it comes to cutting direction, there are downcut and upcut milling. In downcut milling, the cutter pushes the material down, reducing chip exposure. Upcut milling pulls the material upwards, which can create a rougher finish. Each method has its uses, depending on the job’s needs.

What is the difference between face milling and slot milling?

Face milling creates smooth surfaces on large areas, while slot milling makes narrow grooves or slots.

What are the advantages of downcut versus upcut milling?

- Downcut milling gives a cleaner surface finish.

- Upcut milling may pull chips away but can leave a rough surface.

Selection of Appropriate Milling Cutter for Grooves

Criteria for choosing the right cutter type. Comparison of cutter materials (HSS, carbide, etc.).Choosing the right milling cutter is crucial for successful groove machining. Here are a few key points to consider:

- Type of Cutter: Different cutters serve different purposes. Know your needs before deciding.

- Cutter Material: Common options include HSS (High-Speed Steel) and carbide. HSS is cheaper but wears out faster. Carbide lasts longer and cuts better, but it’s more expensive.

- Cutter Size: Choose a size that fits your project. Smaller grooves may need smaller cutters.

The right choice can improve performance and save time and money. It’s like picking the right tool from your toolbox!

What is the best material for milling cutters?

The best material often depends on the job. For tough materials, carbide is best. For softer materials, HSS works well.

Material comparison table:

| Type | Durability | Cost |

|---|---|---|

| HSS | Medium | Low |

| Carbide | High | High |

Programming and Tool Path Strategies

CNC programming considerations for groove machining. Toolpath optimization for efficiency and precision.CNC programming for groove machining demands sharp focus. It’s all about finding the right path! Remember, every cut counts, and an efficient toolpath saves time and materials. A well-planned strategy can make a huge difference in precision and efficiency. For example, minimizing tool movement can cut down on wasted time and energy. Here’s a quick look at key factors:

| Factor | Description |

|---|---|

| Feed Rate | Speed at which the cutter moves. |

| Depth of Cut | How deep the cutter goes in one pass. |

| Tool Selection | Picking the right cutting tool for the job. |

Efficient programming helps reduce mistakes and costs. So, remember, “Cut smart, not hard!” It’s like doing math – if you take your time to plan, you won’t end up with a messy answer!

Challenges in Groove Machining

Common issues faced during groove machining. Troubleshooting and solutions for machining defects.Groove machining can have some bumps along the way. Here are common issues:

- Tool wear: Blunt tools can create poor grooves.

- Vibration: Unstable setups can lead to uneven cuts.

- Chip buildup: Particles may block the tool path.

To fix these problems, it helps to check your tools regularly. Adjusting the speed and feed rates can reduce vibration. Keeping the area clean prevents chip issues. These steps can lead to better grooves!

What are some solutions for machining defects?

To tackle machining defects, ensuring proper tool alignment is key. Regular maintenance of machines can also help. Using the right cutting speeds can improve outcomes too.

Innovations in Milling Cutter Designs

Recent advancements in milling cutter technology. Future trends in groove machining strategies.Modern milling cutters have seen exciting changes. New designs help make machining faster and more precise. These improvements are making it easier to create specific grooves. Cutting-edge materials make tools last longer. Additionally, some are even eco-friendly!

- Tools now last longer.

- New shapes cut faster.

- Eco-friendly materials are used.

- Advanced coatings improve performance.

Looking ahead, future trends show a focus on smart technology. Machines may soon learn and adapt for better accuracy. This means less waste and more efficiency in groove machining strategies. The future is bright for these innovations!

What are the latest advancements in milling cutter technology?

Recent advancements include improved materials and sharper designs that enhance precision and durability.

Key features of new designs:

- Smart technology for quicker setup.

- Precision-engineered shapes.

- Innovative coatings for longer life.

Best Practices for Groove Machining

Maintenance and care for milling cutters. Tips for maximizing the lifespan of cutters in groove applications.Keeping milling cutters in top shape is key to getting the best grooves. First, clean them regularly to prevent buildup. A quick wipe can save you big headaches later! If your cutter gets a bit dull, don’t panic—sharpen it! This simple step can add hours to its life. Also, store them safely away from moisture. If only they could appreciate a cozy home like we do! Lastly, check settings regularly. The right speed can work wonders.

| Tip | Benefit |

|---|---|

| Regular Cleaning | Prevents buildup |

| Sharpen Dull Cutters | Extends lifespan |

| Safe Storage | Reduces rust |

| Check Settings | Improves performance |

Remember, even cutters like a little TLC! Keep these tips handy, and you’ll groove through your projects like a pro!

Conclusion

In conclusion, using a milling cutter groove machining strategy helps create precise grooves in materials. You should choose the right cutter for better results. Understanding feed rates and cutting speeds is crucial. We encourage you to experiment with different strategies. For more details, consider reading additional resources or guides on machining techniques to become even more skilled!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Milling Cutter Groove Machining Strategy:Sure! Let’s talk about milling cutter groove machining. This is a way to cut shapes out of materials, like metal or wood. We use special tools called milling cutters to make grooves, which are like deep lines or channels. You can think of it as carving out a path. It helps make things look nice and fit together better!

Sure! Just ask your question, and I’ll be happy to help you!

What Factors Should Be Considered When Selecting The Appropriate Milling Cutter For Groove Machining?When choosing a milling cutter for groove machining, you should think about a few things. First, consider the size of the groove you need. Next, look at the material you are cutting. Some cutters work better on harder materials. Also, check the speed of the machine you are using, because it affects how well the cutter works. Lastly, remember your budget; some cutters cost more than others.

How Does The Geometry Of A Groove Affect The Milling Strategy And Toolpath Planning?The shape of a groove changes how we cut it. If the groove is deep or wide, we need to plan carefully. We can’t use the same tool for every groove. By knowing the groove’s shape, we choose the right tool and path to make a clean cut. This helps us finish our work faster and better!

What Are The Advantages Of Using Different Types Of Milling Cutters (E.G., End Mills Vs. Shell Mills) For Machining Grooves?Using different milling cutters, like end mills and shell mills, helps us make grooves better. End mills are great for making precise and detailed shapes. They can get into tight spots easily. Shell mills are bigger and cut wider grooves faster. Choosing the right cutter helps us work efficiently and get the best results!

How Can Machining Parameters Such As Feed Rate And Spindle Speed Be Optimized For Efficient Groove Machining?To optimize machining parameters like feed rate and spindle speed, you should start by testing different settings. The feed rate is how fast the tool moves. The spindle speed is how fast the tool spins. You can try slower and faster speeds to see what works best. Always check the results to find the best settings for making grooves.

What Are Some Common Challenges Faced During Groove Machining, And What Strategies Can Be Employed To Overcome Them?Groove machining can be tricky. One challenge is keeping the tool from wearing out too fast. You can fix this by using better materials or slowing down a bit. Another problem is getting the right shape. We can measure carefully and adjust the machine to make it perfect. Finally, sometimes the machine can shake. We can solve this by making sure everything is tight and stable.