Have you ever wondered how machines carve and shape metal? The secret lies in milling machines and their tool holders. These special tools grip and secure cutting bits that do the hard work. But did you know there are various types of milling machine tool holders?

Imagine a toolbox filled with different keys, each opening a different lock. That’s what milling machine tool holders are like. Each type serves a unique purpose in making metal parts. This variety helps workers create everything from tiny gears to giant engine blocks.

Surprisingly, the right tool holder can improve safety and efficiency in the workshop. Choosing the wrong one might slow you down or even lead to accidents. Are you curious to learn about the different types? Let’s explore the world of milling machine tool holders together!

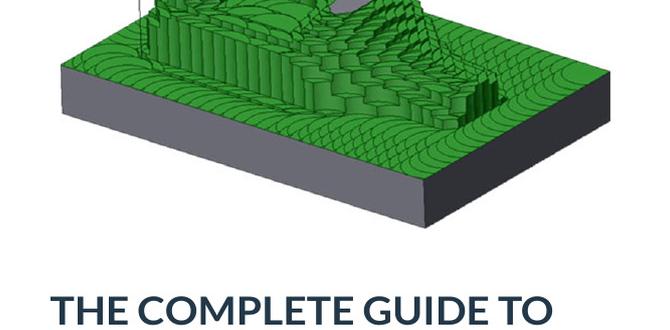

Milling Machine Tool Holder Types: A Comprehensive Guide

Milling Machine Tool Holder Types

Milling machines have various tool holder types that significantly affect performance. Common types include collet chucks, end mill holders, and face mill adapters. Each holder has unique features that cater to different tasks. For example, collet chucks are perfect for small, precise jobs. Did you know that using the right tool holder can improve tool life and cut quality? Choosing wisely can make a big difference in your projects.3. Collet Holders

Explanation of collet types and their applications. Advantages and disadvantages of using collet holders.Collet holders are handy tools that grip a shank tightly. They come in different types, such as slip collets, which allow some movement, and grip collets, which hold things firmly. These holders are widely used in milling machines for their strength and versatility. However, they can be tricky to set up and might slip if not tightened properly.

| Type | Advantages | Disadvantages |

|---|---|---|

| Slip Collet | Easy to adjust | May not hold as tightly |

| Grip Collet | Strong grip | Can be hard to remove |

In the end, collet holders are like a good friend. They lift you up but can sometimes let you down if you don’t give them the attention they need!

4. End Mill Holders

Characteristics of end mill holders and their uses. Comparison with other types of tool holders.End mill holders are important for keeping tools steady during machining. They can have unique shapes, like tapered ends or collar designs, which help with precise cuts. These holders fit snugly and reduce tool movement, leading to a smooth finish. Compared to other tool holders, like collet holders, end mill holders tend to offer better stability. So, they are used for heavy-duty tasks and in making larger parts.

What are the key benefits of end mill holders?

End mill holders provide excellent grip and stability. This ensures less vibration and better accuracy during cuts. They are easy to change and fit various milling machines, making them versatile.

Characteristics of end mill holders:

- Strong grip for less vibration

- Various shapes for different tasks

- Quick tool changes for efficiency

- Sturdy materials for durability

5. Shrink Fit Tool Holders

Description of shrink fit technology and its benefits. Ideal applications for shrink fit tool holders.Shrink fit tool holders use a special method to hold cutting tools tightly. They use heat to expand the holder. Once cooled, it grips the tool firmly. This design reduces vibrations and increases accuracy. It works best for precise machining tasks.

- Benefits: Strong grip, less tool vibration, and greater precision.

- Ideal Applications: Aerospace manufacturing, automotive parts, and intricate machining.

What are the benefits of shrink fit tool holders?

Shrink fit tool holders offer better tool grip and stability. They reduce vibrations, which leads to higher accuracy in machining. They are lightweight and can handle various materials, making them a smart choice for precise jobs.

7. Face Mill Holders

Definition and usage of face mill tool holders. Key features that enhance machining performance.Face mill holders are special tools used in milling machines. They hold cutting tools, helping to shape materials. These holders make work easier and faster. Key features include:

- Stability – They keep the tool steady during use.

- Versatility – They can fit different tools for various jobs.

- Durability – Built from strong materials to last longer.

With the right face mill holder, machining performance improves. It leads to cleaner cuts and reduces production time, making every cut count.

What are face mill holders used for?

Face mill holders are used to secure cutting tools in milling machines. They help shape and finish materials effectively.

8. Quick Change Tool Holders

Explanation of quick change systems and their efficiency. Applications in highproduction environments.Quick change tool holders make life easier in busy workshops. They let workers swap tools quickly, saving time and boosting productivity. Imagine changing tools faster than you can say “Jack be nimble!” In high-production environments, this speed is vital. It helps keep machines running smoothly, which means more products made in less time. Plus, these holders fit snugly, so no tools go missing during the rush. Here’s a quick look at some key advantages:

| Advantage | Description |

|---|---|

| Speed | Change tools in seconds rather than minutes. |

| Efficiency | Less downtime means more production. |

| Precision | Consistent tool positioning for high-quality results. |

In short, quick change tool holders are like superheroes for machines, swooping in to save the day with speed and efficiency!

9. Choosing the Right Tool Holder for Your Needs

Factors to consider when selecting a tool holder. How to determine compatibility with milling machines.Choosing the right tool holder can feel like searching for a needle in a haystack—if the haystack were in the middle of a tricky jungle! First, think about size and shape. Different tool holders fit various milling machines. You can check this compatibility using specifications provided by manufacturers. Don’t forget to consider material! Certain materials work better with specific tools. Finally, keep your project needs in mind. If you’re milling wood, a simple holder might do, but for metal, go for something stronger!

| Factor | Importance |

|---|---|

| Size | Must match the machine |

| Material | Determines strength and durability |

| Project Needs | Choose based on the material being milled |

10. Maintenance and Care of Tool Holders

Best practices for maintaining tool holders for longevity. Common issues and troubleshooting tips.Keeping your tool holders in tip-top shape is key for long life and great performance. Regular cleaning is important—think of it like giving them a bubble bath! Also, store them in a dry place to avoid rust, like putting them in a cozy, dry bed. Common issues include wear and tear, which can lead to improper fitting. If your tools don’t fit snugly, it might be time to replace them. Remember, a happy tool holder makes for a happy milling machine!

| Issue | Solution |

|---|---|

| Rust on Tool Holder | Clean and apply rust inhibitor |

| Poor Fitting | Check for wear; replace if necessary |

| Dirt Build-Up | Regular cleaning with appropriate tools |

Conclusion

In summary, understanding milling machine tool holder types is essential for effective machining. Each type serves different needs. You can choose from collet chucks, end mill holders, and more. By learning these options, you can improve your projects. We recommend exploring specific tool holders further to see what fits your work best. Happy milling!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Milling Machine Tool Holder Types:Milling machines use special parts called tool holders to hold cutting tools. There are different types, like Collet Chuck and End Mill Holder. You choose a type based on what you’re cutting. Each type helps make sure the tool works well and stays steady. It’s important to use the right one for your project!

Sure! Please share the question you’d like me to answer.

What Are The Main Types Of Tool Holders Used In Milling Machines And How Do They Differ In Design And Application?In milling machines, there are three main types of tool holders: end mill holders, collets, and shell mill holders. End mill holders hold flat tools tightly and are very strong. Collets are small holders that grip round tools tightly. Shell mill holders let you change tools quickly and are used for larger jobs. Each type works a bit differently depending on your project needs.

How Does The Choice Of Tool Holder Affect The Machining Process And The Quality Of The Finished Part?The tool holder is like a special grip for the tool in machines. When you choose the right one, it holds the tool steady and helps it cut better. If it’s not good, the tool can shake and make rough parts. This means the finished part might not look or work well. So, picking the right tool holder is very important!

What Are The Advantages And Disadvantages Of Using Collet Chucks Compared To End Mill Holders In Milling Operations?Collet chucks are great because they hold the tool snugly, making it less likely to slip. This helps you cut better and more accurately. But, collet chucks can wear out faster and be harder to change. End mill holders are easier to switch tools but might not hold the tool as tight. So, it’s about choosing what you need for your work!

In What Scenarios Would A Milling Machine Benefit From Using High-Precision Tool Holders Like Shrink Fit Or Hydraulic Holders?High-precision tool holders, like shrink fit or hydraulic holders, help milling machines do a better job. You should use them when making tiny or detailed parts. They hold the tools very tightly, so they don’t move around. This makes the cuts smoother and more accurate. If you want your work to be perfect, these tool holders are the way to go!

How Do Factors Such As Tool Holder Material And Taper Type Influence The Performance And Longevity Of Milling Machine Tool Holders?The material of the tool holder affects how strong and tough it is. Harder materials last longer and withstand heat better. The taper type, which is how the holder fits the machine, helps keep everything steady while we work. If the fit is good, it improves performance and reduces wear and tear. This means our tools will last longer and work better!