Quick Summary: For beautiful Delrin trochoidal milling, a 35-degree TiAlN ball nose end mill is essential. It helps cut smoothly, reduces heat, and prevents melting, leading to clean, precise finishes beginners can achieve.

Hey makers! Daniel Bates here from Lathe Hub, and I get it. You’re looking at Delrin, that super slick plastic, wanting to create some amazing parts with trochoidal milling. But maybe your finishes aren’t quite there, or you’re worried about melting that delicious plastic. It can be a bit frustrating when your tools don’t play nicely with your material. Well, let’s sort this out! Today, we’re diving deep into why a specific tool – the 35-degree TiAlN ball nose end mill – is your secret weapon for stunning Delrin trochoidal milling. We’ll break down exactly why this combo works so well, what makes it special, and how you can use it to get those professional-looking results, even if you’re just starting out.

The Magic Combo: 35-Degree TiAlN Ball Nose End Mill for Delrin

When we talk about milling Delrin, especially using the efficient trochoidal method, the right cutting tool makes all the difference. Think of it like using the right screwdriver for a screw; the wrong one makes a mess. For Delrin, the 35-degree TiAlN ball nose end mill is a standout choice for beginners. Let’s unwrap why this specific combination is so effective.

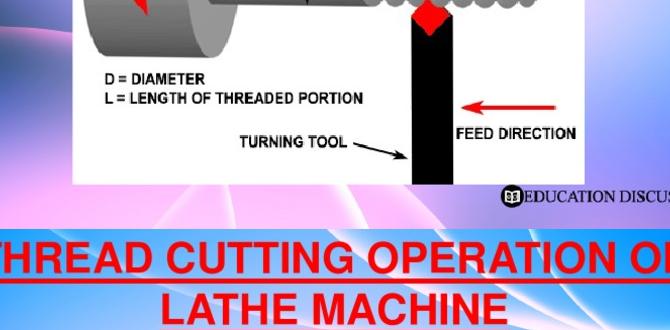

What is Trochoidal Milling Anyway?

Before we dive into the tool, let’s quickly touch on trochoidal milling. It’s a high-speed machining technique that uses small, circular movements of the tool to remove material. Imagine a tiny, spiraling path. This method is fantastic for creating pockets and slots because it keeps the cutting tool engaged with the material in a controlled way. It’s efficient, reduces heat buildup compared to traditional slotting, and can be much faster. However, it requires tools that can handle the dynamic cutting action.

Why Delrin Likes This Specific Tool

Delrin, also known as acetal or POM (Polyoxymethylene), is a fantastic engineering thermoplastic. It’s strong, stiff, has low friction, and is dimensionally stable. But it’s also a plastic that can deform and melt if too much heat is generated. This is where our 35-degree TiAlN ball nose end mill shines.

The Ball Nose Shape: Smooth Curves and Details

A ball nose end mill has a rounded tip, like a ball. This shape is perfect for creating curved surfaces and detailed features. In trochoidal milling, the rounded tip helps the tool smoothly transition between its circular paths, reducing stress on the cutting edges and the workpiece. For those intricate designs or smooth blends in your Delrin parts, the ball nose is key. It avoids sharp corners that can snag or create stress points.

The 35-Degree Helix Angle: The Sweet Spot for Plastics

End mills come with different helix angles (the angle of the flutes, which are the spiral grooves that cut the material). For plastics like Delrin, a lower helix angle is generally better. A 35-degree helix is often considered a sweet spot. Here’s why:

- Reduced Cutting Forces: Lower helix angles typically exert less force on the material. This means less chance of the Delrin deforming or the tool digging in too aggressively.

- Better Chip Evacuation: While plastics don’t produce chips like metal, they do produce swarf (plastic shavings). The 35-degree angle helps in clearing this swarf effectively, preventing it from clogging the flutes and causing overheating.

- Smoother Finish: Compared to higher helix angles, the 35-degree angle often results in a smoother surface finish on plastics, which is exactly what we want for stunning Delrin parts.

TiAlN Coating: Protection and Performance

TiAlN stands for Titanium Aluminum Nitride. It’s a high-performance coating applied to the cutting tool. For Delrin and other plastics, this coating offers several benefits:

- Heat Resistance: Delrin can generate heat when machined. TiAlN coating is very hard and resists high temperatures, which helps prolong the life of the end mill and prevents it from softening or degrading.

- Reduced Friction: The coating acts as a lubricant, reducing friction between the tool and the Delrin. This means less heat is generated, and the cutting process is smoother.

- Increased Tool Life: By combating heat and friction, the TiAlN coating significantly extends the usable life of your end mill, saving you money and fewer tool changes.

Putting It All Together for Delrin

When you combine these three features – the ball nose shape for smooth contours, the 35-degree helix angle for controlled cutting and chip clearance, and the TiAlN coating for heat and friction reduction – you get an end mill that’s exceptionally well-suited for trochoidal milling Delrin. It’s designed to cut cleanly, minimize melting, and produce those beautiful, precise finishes that make your projects stand out.

Choosing Your 35-Degree TiAlN Ball Nose End Mill: What to Look For

Now that we know why this tool is great, let’s talk about how to pick the right one for your CNC machine and your projects. It’s not just about grabbing any end mill with these specs; a few details can make your milling experience even better.

Material of the End Mill

Most high-quality end mills, especially those with advanced coatings like TiAlN, are made from solid carbide. Carbide is extremely hard and holds its sharp edge much better than high-speed steel (HSS), making it ideal for milling plastics and softer metals. Always look for a “Solidcarbide” end mill.

Number of Flutes

The number of flutes (the cutting edges along the spiral) on an end mill affects how it cuts. For plastics, especially in high-speed applications like trochoidal milling, fewer flutes are often preferred.

- 2-Flute End Mills: These are generally the best choice for plastics. They provide excellent chip clearance, which is crucial for preventing Delrin from melting and clogging the flutes. The larger space between the flutes allows the swarf to escape easily.

- 3-or-4-Flute End Mills: While common in metal machining, these can sometimes struggle with chip evacuation in plastics, leading to heat buildup and melted material. Stick with 2-flute for Delrin when possible.

Diameter and Cutting Length

The diameter of your end mill will depend on the size of the features you need to create. Ball nose end mills are often available in a wide range of diameters. The cutting length refers to how far down the shank the flutes extend. For most Delrin milling, a standard cutting length is usually sufficient. However, if you’re milling deep pockets, you might need an end mill with a longer flute length. Always ensure the cutting diameter is appropriate for the detail you want and for the trochoidal stepover you plan to use.

Shank Type

Most end mills have a straight shank, which fits into your CNC machine’s collet. Ensure the shank diameter matches your collet size. Some end mills might have a Weldon shank, which includes a flat spot for a set screw in some tool holders – this is less common for smaller end mills used in hobbyist machines but good to be aware of.

Brand and Quality

While it might be tempting to go for the cheapest option, investing in a reputable brand for your cutting tools is usually worth it. High-quality end mills are manufactured to tighter tolerances, have sharper edges, and their coatings are applied more effectively. This leads to better performance, longer tool life, and more reliable results – something we all want!

Example Specs to Look For:

When searching online or in a tool catalog, you’ll be looking for something like:

- Type: Ball Nose End Mill

- Coating: TiAlN (or Ti, Al)N

- Helix Angle: 35 degrees (sometimes listed as “low helix” or specific angles like 35°)

- Material: Solid Carbide

- Flutes: 2

- Diameter: (e.g., 1/8″, 1/4″, 3mm, 6mm – choose based on your project needs)

Setting Up Your CNC for Delrin Trochoidal Milling

Having the right tool is only half the battle. Setting up your CNC machine correctly is crucial for success. Let’s look at the key parameters for milling Delrin with your 35-degree TiAlN ball nose end mill.

Speeds and Feeds: The Golden Rules

Speeds and feeds are perhaps the most critical settings. They determine how fast the tool spins (spindle speed, RPM) and how fast it moves through the material (feed rate, inches per minute or millimeters per minute).

- Spindle Speed (RPM): For Delrin and a 2-flute end mill, you’ll typically want to run at a relatively high RPM. This leverages the benefits of high-speed machining. A good starting point might be anywhere from 10,000 to 25,000 RPM, depending on your machine’s capabilities and the end mill diameter. Smaller end mills often require higher RPMs.

- Feed Rate (IPM/MPM): The feed rate dictates how much material is removed per rotation of the tool. You want to feed fast enough to create a clean chip, but not so fast that you overload the tool or the machine. Because we’re using trochoidal milling, the chip load (the amount of material removed by each cutting edge in each revolution) is key. For Delrin with a 2-flute end mill, a chip load might range from 0.001″ to 0.004″ (0.025mm to 0.1mm).

Important Note: Always consult the end mill manufacturer’s recommendations for speeds and feeds, or use a reliable speeds and feeds calculator. These are just starting points.

An excellent resource for understanding machining basics, including speeds and feeds, is the National Institute of Standards and Technology (NIST) Manufacturing Extension Partnership, which provides guidance on advanced manufacturing topics.

Trochoidal Milling Parameters

Trochoidal milling involves specific parameters that differ from traditional pocketing:

- Stepover: This is the distance the tool moves sideways with each small circle. For trochoidal milling, a small stepover is essential. It keeps the tool from rubbing and overheating. A stepover of 10-30% of the tool diameter is common. For Delrin, starting on the lower end (10-20%) is often safer.

- Stepdown (Axial Depth of Cut): This is how deep the tool cuts on each pass. Plastics can machine with relatively high stepdowns compared to metals, but always consider the tool’s rigidity and your machine’s stability. A common starting point might be 0.5 to 1 times the tool diameter, but smaller stepdowns often yield better finishes. For Delrin, you can often get away with aggressive stepdowns, but balancing this with surface finish is key.

- Step in (Radial Depth of Cut): In trochoidal milling, this is effectively your stepover. The software using trochoidal paths will manage the radial engagement.

- Ramp Angle: If your CAM software allows, setting a shallow ramp angle (e.g., 5 degrees or less) for the tool to enter the material can be beneficial. This helps the tool engage gradually.

Coolant/Lubrication

Delrin doesn’t typically require the same flood coolant as metals. However, some form of lubrication or cooling can significantly improve surface finish and tool life. For Delrin:

- Compressed Air Blast: Often sufficient, a targeted blast of compressed air can help clear swarf and keep the cutting zone cool.

- Mist Coolant: A light mist of a plastic-safe coolant can be very effective. It lubricates the cut and removes heat without flooding the machine. Avoid oil-based coolants unless specifically recommended for the plastic, as they can sometimes cause issues or be messy.

- Dry Machining: With the right speeds, feeds, and tool, you can sometimes machine Delrin dry. However, this usually results in a slightly rougher finish and increased tool wear compared to using some form of cooling.

Always be mindful of fume production when machining plastics. Ensure good ventilation in your workshop. You can learn more about workshop safety and ventilation, including for plastics, from resources like the Occupational Safety and Health Administration (OSHA), particularly regarding dust and fumes.

Workholding

Securely holding your Delrin workpiece is paramount. Use clamps, vises, or double-sided tape that won’t interfere with the tool path. Make sure the workpiece is flat and won’t move during machining. Delrin is relatively stiff, but aggressive cuts could still dislodge a poorly secured part.

Step-by-Step Guide: Trochoidal Milling Delrin with Your TiAlN Ball Nose End Mill

Let’s walk through a typical process to achieve those amazing Delrin trochoidal milling results. This assumes you have your 35-degree TiAlN ball nose end mill selected and your CNC machine ready.

Step 1: Design Your Part and Create Your CAM Toolpath

Using your CAD (Computer-Aided Design) software, create the 2D or 3D model of your part. Then, import this into your CAM (Computer-Aided Manufacturing) software. When setting up your toolpath for pockets or slots:

- Select your 35-degree TiAlN ball nose end mill as the tool.

- Choose a “Trochoidal Milling” or “High-Speed Pocketing” strategy.

- Input your desired diameter, number of flutes (2), and coating (TiAlN).

- Set the appropriate spindle speed (RPM) and chip load.

- Define your stepover (e.g., 15% of tool diameter) and stepdown (e.g., 0.5x tool diameter).

- Configure your coolant strategy (e.g., air blast).

- Set your safe Z height and rapid moves.

Simulate your toolpath in the CAM software to check for any potential collisions or issues before generating the G-code.

Step 2: Prepare Your CNC Machine and Workpiece

Safely secure your Delrin workpiece to your machine bed using your chosen workholding method. Ensure it’s firmly in place and won’t vibrate or move. Insert your 35-degree TiAlN ball nose end mill into the collet and tighten it securely.

Step 3: Set Your Zero Points (Work Coordinate System)

Using your machine’s probe or a manual indicator, set your X, Y, and Z zero points accurately on your workpiece. This tells the machine where to start cutting.

Step 4: Load and Verify G-Code

Load the generated G-code into your CNC machine’s controller. Perform a “dry run” by executing the program with the spindle off and the Z-axis several inches above the workpiece. Watch to ensure the machine follows the intended path and all movements are correct. This is a critical safety step!

Step 5: Initiate the Cut with Coolant/Air

With the dry run confirmed, set the Z-zero to the top of the material. Start your coolant or compressed air system. Turn on the spindle to the programmed RPM. Once the spindle is up to speed, begin the cutting program.

Step 6: Monitor the Machining Process

Watch and listen to the machine as it cuts. You’re looking for:

- Smooth Cutting Sound: A consistent, light cutting sound is ideal. Banging or chattering can indicate issues with speeds, feeds, or tool engagement.

- Swarf Evacuation: Ensure the Delrin swarf is being cleared away effectively by the air blast or mist. It shouldn’t be piling up or melting.

- Overheating: If you see smoke or smell melting plastic, stop the machine immediately. This usually points to an issue with speeds/feeds, stepover, or chip evacuation.

Step 7: Inspect the Finished Part

Once the program has finished, wait for the spindle to stop completely. Carefully remove the finished Delrin part. Inspect it for surface finish, dimensional accuracy, and any signs of melting or burning. A properly executed trochoidal milling operation with this tool should yield a very clean, smooth finish.

Maintenance and Care for Your End Mill

Your 35-degree TiAlN ball nose end mill is an investment. Taking a little time for care will ensure it performs reliably for many projects to come.

Cleaning

After each use, clean any residual Delrin swarf off the end mill. A stiff brush is usually effective. If there’s any stubborn residue, a bit of isopropyl alcohol can help