Quick Summary: A TIALN 40-degree ball nose end mill is your go-to tool for achieving smooth, precise, and beautiful finishes on mild steel, especially when you need detailed curves and complex contours. It’s essential for that final, professional touch in your machining projects.

Hey makers! Daniel Bates here from Lathe Hub. Ever look at a finished metal part and wonder how they got those super-smooth, flowing curves and perfect surfaces? Often, it’s down to a specific type of cutting tool. Today, we’re diving into one of my favorites: the TIALN ball nose end mill with a 40-degree helix angle. If you’re working with mild steel and want that professional, chip-free finish, this little gem is going to be your new best friend. It can seem a bit daunting at first, but I promise, we’ll break down exactly why it’s so good and how you can use it to make your projects shine – step by step!

Why Your Projects Need a TIALN 40-Degree Ball Nose End Mill

When you’re machining mild steel, especially for intricate shapes or detailed surface work, the finish is everything. You want smooth transitions, no tool marks, and a clean look that says “quality.” This is where the TIALN 40-degree ball nose end mill really earns its keep. It’s not just a tool; it’s a finishing specialist.

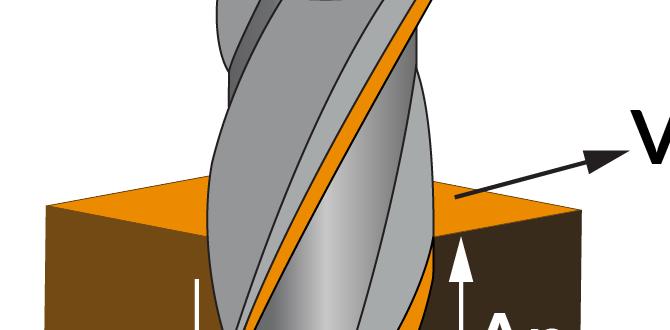

Understanding the Anatomy of the Tool

Let’s look at what makes this tool special:

- Ball Nose: This means the cutting tip is a perfect half-sphere. Imagine a ball – that’s the shape of the end. This allows it to create curved surfaces, fillets, and contours without sharp corners, which are often a source of stress in parts.

- 40-Degree Helix Angle: The flutes (the spiral grooves on the cutter) are twisted at a 40-degree angle. This angle promotes smoother cutting action and better chip evacuation compared to tools with steeper or shallower helix angles. It’s a sweet spot for many materials, including mild steel, offering a good balance of cutting force and surface finish.

- TIALN Coating: This is the secret sauce! TIALN stands for Titanium Aluminum Nitride. It’s a super-hard coating applied to the end mill. Why is this important?

- Increased Hardness: It makes the tool much harder, allowing it to cut tougher materials and resist wear.

- High-Temperature Resistance: When cutting, friction creates heat. TIALN coatings can handle much higher temperatures than uncoated tools without losing their cutting edge. This means you can often run faster cutting speeds.

- Reduced Friction: The coating helps chips slide off the tool more easily, preventing them from welding onto the cutting edge. This means cleaner cuts and a longer tool life.

- Extended Tool Life: All these benefits add up to your end mill lasting much longer.

The Magic of TIALN for Mild Steel Finishing

Mild steel is a common material, but getting a mirror-smooth finish can be tricky. The TIALN coating on a 40-degree ball nose end mill is particularly effective for this because it:

- Minimizes Chatter: The 40-degree helix angle helps to reduce vibration, or chatter, during the cut. Chatter leads to rough surfaces and can damage your tool.

- Evacuates Chips Efficiently: For finishing passes, you don’t want chips recutting into your workpiece. The TIALN coating and the helix angle work together to clear chips away smoothly.

- Produces a Superior Surface Finish: The combination of the ball shape and the optimized helix angle allows the tool to glide over the material, leaving a remarkably smooth surface. Think of it like a finely tuned sculptor’s tool.

- Allows for Higher Cutting Speeds (with care): The heat resistance means you can often push the speeds a bit, which can lead to faster cycle times for your finishing operations. However, always start conservatively and adjust.

This type of end mill is perfect for creating radiused internal corners, blending surfaces, machining 3D contours, and achieving that final polished look on your parts.

When to Choose a TIALN 40-Degree Ball Nose End Mill

You’ve got a project, and you’re wondering if this specific tool is the right one. Here are the key scenarios where it excels:

- Achieving Smooth, Radiused Internal Corners: If your design calls for fillets (smooth, curved inside corners) rather than sharp, 90-degree ones, a ball nose end mill is essential. The 40-degree helix and TIALN coating ensure a clean, chatter-free radius.

- 3D Contour Machining: For parts with complex curved surfaces, like molds, prototypes, or artistic pieces, this end mill is ideal. It can follow the curves smoothly, leaving a consistent finish.

- Final Finishing Passes: When you’ve done your heavy material removal and just need to refine the surface, this tool is your specialist. It’s designed to skim the surface cleanly.

- Machining Mild Steels and Other Materials: While we’re focusing on mild steel here, the TIALN coating makes this an excellent choice for other softer metals like aluminum and brass too, as well as some plastics.

- Reducing Secondary Operations: A good finish from this tool might mean you need less sanding or polishing afterward, saving you time and effort.

Think of it this way: if the goal is a smooth, flowing, and aesthetically pleasing surface on mild steel, especially in contoured areas, this is likely your tool.

Getting Started: Setting Up and Using Your TIALN 40-Degree Ball Nose End Mill

Now that you understand why this tool is so great, let’s get it onto your machine and into the metal safely and effectively. Remember, patience and precision are key when finishing.

Step 1: Safety First!

Before you even touch the machine, make sure you’re set up for safety. This is non-negotiable in any machining operation.

- Eye Protection: Always wear safety glasses or a face shield. Metal chips can fly!

- Hearing Protection: Machines can be loud. Protect your ears.

- Clothing: Avoid loose clothing, jewelry, or anything that could get caught in the machine. Tie back long hair.

- Gloves (with caution): Wear gloves when handling tools and stock, but never when operating the machine, as they can get caught.

- Know Your Machine: Be familiar with the emergency stop button and how to operate your mill safely.

For more comprehensive safety guidelines, you can refer to resources from organizations like the Occupational Safety and Health Administration (OSHA), which provides standards for safe workplace practices, including those in manufacturing environments.

Step 2: Inspect Your Tool and Machine

A quick check can prevent bigger problems.

- End Mill Condition: Check the TIALN coating for any damage or wear. Ensure the cutting edges are sharp and intact. A damaged end mill will produce a poor finish and can break.

- Spindle and Collet: Make sure the machine’s spindle is clean. The collet you’ll use to hold the end mill should be the correct size and clean. Any debris can cause runout, leading to vibration and a bad finish.

Step 3: Secure Your Workpiece

Your mild steel part needs to be held firmly.

- Use Appropriate Clamping: Whether it’s a vise, clamps, or the machine table, ensure your workpiece is rigidly secured. It should not move at all during the machining process. For finishing passes, even slight movement can ruin the surface.

- Check for Stability: Give the workpiece a good shake (before you start the machine, of course!). If it moves, you need to secure it better.

Step 4: Set Up the End Mill in Your Machine

This is where you actually install the tool.

- Select the Correct Collet: Choose a collet that snugly fits the shank of your TIALN ball nose end mill.

- Insert the End Mill: Place the end mill into the collet. Don’t insert it too deep, but ensure enough of the shank is gripped by the collet for stability – typically, the cutting length should not exceed 4 times the diameter when possible.

- Tighten the Collet: Secure the collet in the machine’s spindle according to your machine’s procedure. Make sure it’s tight.

- Consider Tool Length Measurement: Use a tool length setter or probe to accurately set the height of the end mill relative to your workpiece. This is crucial for consistent depth of cut.

Step 5: Setting Cutting Parameters (Speeds and Feeds)

This is a critical step. For finishing, you generally want:

- Slower Spindle Speeds (RPM): While TIALN can handle heat, for finishing, a slower, more controlled speed often yields a better surface by reducing vibration.

- Lower Depth of Cut (DOC): Finishing passes take off a very small amount of material – often just a few thousandths of an inch (e.g., 0.001″ to 0.005″).

- Appropriate Feed Rate: The feed rate (how fast the tool moves across the material) needs to be balanced with your RPM and DOC to maintain a consistent cut and prevent rubbing.

Finding the exact parameters depends on your specific machine, the exact alloy of mild steel, and the size of your end mill. However, as a starting point for a typical finishing pass on mild steel with a 4mm or 6mm TIALN 40-degree ball nose end mill, consider these ranges:

| Parameter | Typical Range for Mild Steel Finishing | Notes |

|---|---|---|

| Spindle Speed (RPM) | 1000 – 3000 RPM | Start lower, listen to the cut. |

| Feed Rate (IPM or mm/min) | 100 – 400 IPM (250 – 1000 mm/min) | Adjust based on finish quality. Too fast can cause rubbing. |

| Depth of Cut (DOC) | 0.001″ – 0.005″ (0.025 mm – 0.125 mm) | Very shallow for finishing. |

| Stepover (percentage of cutter diameter) | 5% – 20% | Smaller stepover for smoother surface. |

Important Note: Always consult the end mill manufacturer’s recommendations if available. You can find machining calculators online or use charts provided by tool manufacturers. For example, Widia (a prominent cutting tool manufacturer) offers resources that can help you calculate appropriate speeds and feeds. Learning to use these resources is a key skill for machinists.

Step 6: Machining the Finish Pass

With everything set up, it’s time to cut.

- Engage the Spindle: Start your spindle at the chosen RPM.

- Initiate the Cut: Carefully feed the end mill into the material at the programmed feed rate and depth. Listen to the sound of the cut. It should be a consistent, gentle whirring or slicing sound, not a harsh grinding or chattering noise.

- Monitor the Cut: Keep an eye on the chip formation. For finishing, you want small, consistent chips. Watch for any signs of excessive heat or vibration.

- Use Coolant/Lubricant (Optional but Recommended): For mild steel, a good quality cutting fluid or mist coolant helps to keep the tool cool, lubricate the cut, and wash away chips. This significantly improves finish quality and tool life.

- Let the Tool Do the Work: Resist the urge to push the tool too fast or too deep. Finishing is about finesse.

- Retract the Tool: Once the programmed path is complete, retract the end mill clear of the material before stopping the spindle and moving to the next operation.

Step 7: Inspect the Finish

The moment of truth!

- Visually Inspect: Carefully examine the surface for tool marks, chatter, or any imperfections.

- Use a Comparator or Gauge: For critical dimensions or surface roughness, use measuring tools like a profilometer or even a simple gauge block to check for accuracy.

- Compare and Adjust: If the finish isn’t perfect, don’t despair. Review your parameters, tool condition, and setup. Was the feed rate too high? Was there slight vibration? A small adjustment might be all you need for the next pass.

Tips for Maximizing Your TIALN 40-Degree Ball Nose End Mill

To get the absolute best out of your TIALN coated ball nose end mill, here are a few extra pointers:

- Rigidity is King: The more rigid your setup (machine, tool holder, workpiece), the better the finish.

- Use the Smallest Effective Diameter: For internal radii, use the smallest diameter ball nose end mill that can create the required radius. A smaller diameter tool often provides a smoother finish in tight areas.

- Consider Toolpath Strategies: In your CAM software (if you’re using one), choose appropriate finishing toolpaths like constant Z or variable Z to ensure the ball nose stays engaged with the surface in the most efficient and smoothest way. Stepping over by a smaller percentage of the tool diameter will naturally create a smoother surface.

- Keep it Clean: After use, clean the end mill to remove any workpiece material or coolant residue. Store it properly to protect the coating.

- Tool Wear Management: TIALN coatings extend tool life significantly, but tools do wear out. Develop a system for monitoring tool wear and replacing tools before they start to degrade your finish quality.

- Material Consistency: Mild steel can vary slightly in hardness. Be prepared to make minor adjustments to your speeds and feeds based on how the material is behaving.

Common Problems and How to Fix Them

Even with the best tools, things can go wrong. Here’s how to troubleshoot common finishing issues when using your TIALN 40-degree ball nose end mill:

| Problem | Possible Causes | Solutions |

|---|---|---|

| Surface is Rough / Tool Marks Visible | Depth of cut too high. | Reduce DOC significantly. |

| Feed rate too high. | Slow down the feed rate. | |

| Machine vibration or chatter. | Check tool holder rigidity, collet runout, workpiece clamping. Ensure tool isn’t sticking out too far. | |

| Tool wear or damage. | Inspect and replace the end mill. | |

| Chips Welded to Tool (Weld Buildup) | Incorrect cutting speed or feed. | Adjust RPM and feed rate. Sometimes a slightly faster feed can help clear chips. |

| Insufficient coolant or lubrication. | Increase coolant flow or use a better lubricant. | |

| Low heat resistance from coating (less likely with TIALN). | Ensure you are using a properly coated tool. Possibly reduce cutting speed if heat is excessive. | |

| Tool Broke | Feed rate too high for DOC. | Slow down feed rate. |

| Workpiece shifted or not clamped properly. | Re-clamp workpiece securely. | |

| Excessive depth of cut. | Reduce DOC. | |

| Tool not inserted correctly in collet. | Ensure proper insertion depth. | |

| Poor Radius Quality (not smooth) | Incorrect toolpath or stepover in CAM. | Reduce stepover percentage. Ensure toolpath strategy is optimized for the ball nose. |

| Tool runout. | Check collet and spindle. |

Remember, diagnosing machining issues is a skill that improves with experience. Don’t be discouraged if your first few attempts aren’t perfect!