Quick Summary:

Use a Tialn ball nose end mill with a 40-degree helix angle for effortless profiling, especially in cast iron. Its design offers excellent chip evacuation and a smooth finish, making complex shapes achievable for beginners.

Hey there, machining enthusiasts! Daniel Bates here from Lathe Hub. Ever find yourself staring at a complex curved surface on your blueprint and thinking, “How on earth am I going to machine that?” It’s a common hurdle, especially when you’re just starting out. The good news is, with the right tools, these challenging profiles become surprisingly manageable. Today, we’re diving deep into a fantastic tool that makes shaping those smooth contours a breeze: the Tialn ball nose end mill with a 40-degree helix angle. This specialized cutter is a game-changer for profiling, and we’ll break down exactly why, how to use it, and where it shines brightest, especially when working with tough materials like cast iron. Stick around, and you’ll be profiling like a pro in no time!

What is a Ball Nose End Mill and Why the 40-Degree Helix?

Let’s start with the basics. An end mill is a type of milling cutter tool. It spins around its axis and moves through a workpiece to cut material. Think of it like a drill that can also cut sideways. Now, a “ball nose” end mill is special because its cutting tip is shaped like half a sphere – a perfect ball. This shape is ideal for creating rounded corners, grooves, and, you guessed it, curved profiles.

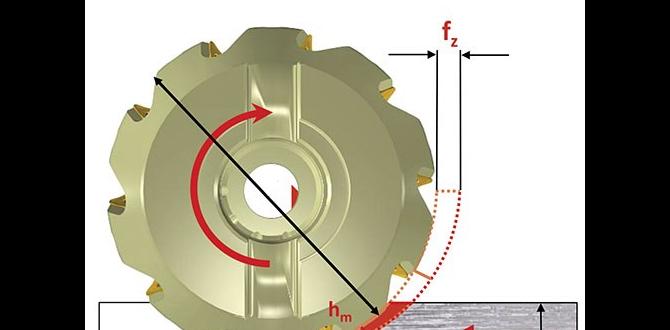

But what about the “40-degree” part? This refers to the helix angle of the flutes (the spiral grooves that run along the cutter). Traditional end mills often have a 30-degree helix. A 40-degree helix angle offers some distinct advantages, particularly for profiling applications. It generally provides:

- Improved Surface Finish: The steeper angle helps to shear the material more cleanly, leading to a smoother finish on your workpiece.

- Better Chip Evacuation: Especially when machining materials that produce stringy chips, like some aluminum alloys, a higher helix angle can help move those chips away from the cutting area more effectively. This prevents chips from recutting, which can damage the tool and the workpiece.

- Reduced Cutting Forces: A 40-degree helix can sometimes lead to lower radial forces, making the cut more stable.

- Good for Contouring: The combination of the ball tip and the helix angle makes these tools superb for following complex contours and creating smooth, flowing surfaces.

When we specifically talk about a “Tialn” ball nose end mill, “Tialn” usually refers to a specific TiAlN (Titanium Aluminum Nitride) coating. This coating is super hard and can withstand higher temperatures, making it excellent for machining tougher materials like steels and cast irons without wearing out too quickly. It’s like putting a tiny, heat-resistant shield on your cutting tool!

Why Choose a 40-Degree Tialn Ball Nose End Mill for Profiling?

Profiling involves cutting along the perimeter of a shape. When that shape has curves, rounded edges, or complex 3D contours, a ball nose end mill is your go-to tool. The 40-degree helix angle, combined with the Tialn coating, makes it particularly well-suited for these tasks, especially when accuracy and a great surface finish are key.

Here’s why this specific configuration is so great for profiling:

- Smooth Transitions: The ball tip naturally creates smooth, flowing cuts. When you’re moving the cutter along a curved path, the rounded tip ensures there are no sharp edges or steps left behind, resulting in a seamless transition from one point to the next.

- Versatility in Depth of Cut: Because the tip is a full radius, you can take varying depths of cut along a contoured surface without changing the effective diameter of your cut at the point of contact. This is crucial for maintaining consistent profiling.

- Handling Tough Materials: Cast iron, while not as hard as hardened steel, can be abrasive and brittle. The Tialn coating on the end mill provides the necessary wear resistance and thermal stability to cut through cast iron effectively, reducing tool wear and preventing premature failure. The 40-degree helix also helps manage the type of chips cast iron produces, which can sometimes be chunky and abrasive.

- Reduced Chatter: A well-designed 40-degree helix angle can help dampen vibration, or chatter, which is a common problem in milling. Less chatter means a better surface finish and longer tool life.

- Achieving Intricate Details: For hobbyists and professionals alike, the ability to create detailed features is essential. A ball nose end mill allows for the machining of fillets, rounded pockets, and complex 3D shapes that would be very difficult or impossible with other types of cutters.

When you’re aiming for a professional-looking finish on your contoured parts, especially in materials like cast iron where surface finish can be a challenge, a Tialn ball nose end mill with a 40-degree helix angle is a powerhouse tool. It’s designed to excel where other tools might struggle.

When to Use Your 40-Degree Tialn Ball Nose End Mill

This specialized end mill isn’t for every job, but when the job calls for it, it’s indispensable. Here are the prime scenarios where you’ll want to reach for your 40-degree Tialn ball nose end mill:

1. Machining Curved Surfaces and Contours

This is its bread and butter. Think of creating:

- Draft Angles: Essential for parts that need to be released from a mold, such as in die-casting or injection molding.

- Radiused Edges and Corners: For aesthetics, stress relief, or smoother transitions between surfaces.

- Complex 3D Shapes: Sculpting, creating artistic elements, or detailed component geometries.

- Impellers and Turbine Blades: These often have intricate, smooth curves where precision is paramount.

2. Finishing Passes

Because of their ability to leave an excellent surface finish, ball nose end mills are often used for the final “finishing” pass in a machining operation. After a roughing end mill has removed most of the material, a ball nose end mill can come in to clean up the surface, especially in contoured areas, leaving it smooth and ready for inspection or further processing.

3. Working with Cast Iron

As we’ve touched upon, cast iron is a material that benefits greatly from the Tialn coating. It’s abrasive, and standard coatings can wear down quickly. The Tialn coating offers superior hardness and heat resistance, making it ideal for:

- Engine Blocks and Heads: Many components of engines are made from cast iron and require precise profiling.

- Machine Bases and Frames: These often feature cast iron construction with complex surfaces.

- Decorative Castings: For artistic or architectural pieces.

The 40-degree helix helps manage the chip load effectively when cutting cast iron, preventing excessive tool wear and ensuring a cleaner cut.

4. Creating Rounded Pockets and Cavities

Need to create a pocket with a nice, smooth radius at the bottom? A ball nose end mill is perfect for this. You can plunge it into the material and mill out the pocket, leaving a perfectly radiused internal corner.

5. Engraving and Texturing

While not its primary purpose, the fine ball tip can be used for very detailed engraving or creating textured surfaces on a workpiece.

Understanding End Mill Specifications: What to Look For

When you’re selecting your 40-degree Tialn ball nose end mill, a few key specifications will help you make the right choice for your project:

Here’s a quick breakdown of what you’ll see on the packaging or in a catalog:

| Specification | What it Means | Why it Matters for Profiling |

|---|---|---|

| Diameter (e.g., 6mm, 1/4 inch) | The overall width of the cutting head. | Determines the smallest radius you can achieve and the area you can cover in one pass. Smaller diameters are for more intricate details. |

| Number of Flutes (e.g., 2, 3, 4) | The number of cutting edges on the tool. | More flutes (e.g., 4) are better for finishing in harder materials with good chip clearance. Fewer flutes (e.g., 2) are good for softer materials or roughing, as they provide better chip evacuation. For a 40-degree helix Tialn in cast iron, 2 or 3 flutes are common for finishing. |

| Coating (Tialn) | Titanium Aluminum Nitride coating. | Provides excellent hardness, heat resistance, and lubricity for cutting tough materials like cast iron and steel. Significantly extends tool life. |

| Helix Angle (40 degrees) | The angle of the spiral flutes. | As discussed, this angle promotes better chip evacuation and a smoother surface finish, ideal for profiling and contouring. |

| Ball Radius (e.g., 3mm, 1/8 inch) | Half the diameter of the ball nose tip. | This is the radius of the corner it will create. A smaller radius allows for finer detail. For a full ball nose, the radius is half the diameter of the tool. |

| Overall Length & Length of Cut | How long the entire tool is and how much of it can actually cut. | Ensures the tool is long enough to reach your workpiece without crashing into the tool holder or machine. |

Using this information, you can pick the right size and type of end mill for your specific profiling task. For example, if you need to create a small internal fillet, you’d choose a smaller diameter ball nose end mill.

Step-by-Step Guide: Using Your 40-Degree Tialn Ball Nose End Mill for Profiling

Ready to put your new tool to work? Here’s a straightforward guide to get you started with effortless profiling. Remember to always prioritize safety!

Step 1: Safety First!

Before you do anything, ensure you’re dressed for the job. Wear safety glasses or a face shield, appropriate work clothing, and no loose jewelry or gloves that could get caught in the spinning machine. Make sure your workpiece is securely clamped and your machine is ready.

Step 2: Select Your End Mill

Choose the correct diameter and ball radius based on your part’s design. For cast iron with a 40-degree helix and Tialn coating, you’re already on the right track. Ensure the end mill is clean and free from damage.

Step 3: Set Up Your Machine

Mount the end mill securely in your machine’s spindle. Use a collet that matches the shank diameter of your end mill for the best runout and holding power. Ensure there are no vibrations or wobbles when you spin the spindle by hand.

Step 4: Determine Your Cutting Parameters

This is crucial. The right speed and feed rate will make a huge difference in cut quality and tool life. For cast iron, you generally need to run at a slower surface speed than you would for aluminum, but faster than very hard steels. A good starting point for uncoated cast iron might be:

- Spindle Speed (RPM): 300-600 RPM

- Feed Rate: 0.001 to 0.003 inches per tooth (IPT)

- Depth of Cut (Axial): For finishing passes, this is usually very shallow, around 0.005 to 0.020 inches.

- Stepover (Radial): For profiling, this can vary. A smaller stepover (e.g., 10-30% of the tool diameter) gives a smoother finish.

Important Note: These are starting points. Always consult your end mill manufacturer’s recommendations or a reliable machining handbook (like those from The Machinist’s Edge or similar resources) for specific values based on your tool and material. Adjust based on how the cut sounds and looks.

Step 5: Program Your Tool Path (or Manually Mill)

If you’re using a CNC machine, you’ll program a contouring tool path. Ensure your software understands that you are using a ball nose end mill (Type G82 in some CAM software, or simply selecting a ball end mill in the tool library).

If you’re manual milling:

- Set your Z-zero: Touch off on the top surface of your workpiece.

- Set your X/Y origin: Establish where your profile starts.

- Engage the spindle: Bring it up to your desired RPM.

- Peck or Step Down: For profiling along a complex curve, you might make multiple shallower passes rather than one deep pass. This is especially true for finishing.

- Feed: Carefully feed the cutter into the material. For manual milling, use a comfortable and consistent pace.

- Follow the Path: Move the Z-axis to control depth and the X/Y axes to follow your desired profile. A common strategy is to use the ball nose for the final contour passes after a bull-nosed or corner-rounding end mill has established the basic shape, or if you need a full radius.

Step 6: Make the Cut

Start the machine and carefully engage the end mill with the workpiece. Listen to the sound of the cut. A smooth, consistent sound is good; loud chattering or grinding indicates a problem with your parameters (speed, feed, depth, or tool sharpness).

Step 7: Perform Finishing Passes

For the best surface finish, make a final pass with a very shallow depth of cut (e.g., 0.005-0.010 inches) and a moderate stepover (e.g., 10-20% of the tool diameter). This “clean-up” pass is where the 40-degree helix Tialn ball nose end mill truly shines! Ensure coolant is used if specified for cast iron; it helps keep the tool cool and washes away chips.

Step 8: Inspect Your Work

Once the machining is complete, carefully remove the part. Inspect the profiled surface. It should be smooth, with no tool marks, and accurately match your design.

Pros and Cons of Using a 40-Degree Tialn Ball Nose End Mill

Like any tool, it has its strengths and weaknesses. Let’s look at them:

| Pros | Cons |

|---|---|

| Excellent for Radiused and Curved Features: Naturally creates smooth, flowing shapes. | Not Ideal for Square Corners: Cannot create sharp internal corners; requires a secondary tool for true 90-degree internal features. |

| Superior Surface Finish: Especially in finishing passes, produces a very smooth surface. | Limited Material Removal Rate (for roughing): The ball shape isn’t as efficient for bulk material removal as a flat-bottomed end mill. |

| Good Chip Evacuation: The 40-degree helix helps manage chips, especially in materials like cast iron. | Potential for Tool Wear on Sharp Tips: While Tialn is good, the very tip of the ball can still wear over time, affecting the perfect radius. |

| Tialn Coating Enhances Durability: Significantly increases tool life when machining abrasive materials like cast iron and some steels. | Requires Specific Programming/Technique: Toolpath generation needs to account for the ball radius, and manual milling requires careful control. |

| Versatile: Can be used for profiling, cavity machining, and even some detailed work. | Can Be More Expensive: Specialized coatings and geometries can increase the cost compared to basic end mills. |

Alternatives for Profiling

While the 40-degree Tialn ball nose end mill is excellent, it’s good to know about other options you might encounter or use:

- 30-Degree Helix Ball Nose End Mills: A more common helix angle. Often good for softer materials or general-purpose profiling. The 40-degree generally offers slightly better chip evacuation and finish in tougher materials.

- Standard Ball Nose End Mills (Uncoated): Suitable for