Imagine shaping a block of wood into something amazing. With a wood lathe, you can turn that idea into reality. But what if you want to create something round like a bowl? That’s where faceplate turning steps in.

Have you ever thought about how bowls are made? It’s not magic; it’s faceplate turning. This technique lets you spin wood around and sculpt it while it spins. It’s like watching a dancer twirl gracefully, revealing beautiful shapes.

Did you know faceplate turning has been a trick up woodcraft’s sleeve for ages? It’s a simple yet clever way to turn something ordinary into art. Whether you’re a curious kid or a budding woodworker, learning about faceplate turning can be your first step in crafting wonders. So, do you think you’re ready to try?

Mastering Wood Lathe Faceplate Turning Techniques

Exploring Wood Lathe Faceplate Turning

Have you ever watched wood spinning on a lathe? It’s like magic! Wood lathe faceplate turning allows you to create round objects like bowls. The faceplate helps hold the wood steady. Beginners can easily learn this technique. Imagine crafting a wooden bowl to show your friends. Did you know? Ancient people used early lathes to shape wood. Dive into wood lathe faceplate turning and discover a world of creativity!Understanding Wood Lathe Faceplate Turning

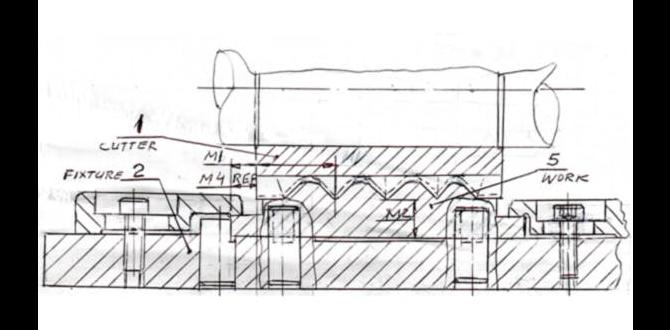

Definition and significance of faceplate turning. Common applications and advantages.Picture this: you’re spinning wood like a DJ spins records. That’s what faceplate turning is all about! This wood lathe technique is all about attaching a piece of wood to a flat plate to carve out amazing shapes and designs. Why is it significant? It lets you create bowls, platters, and even funky sculptures! What’s more, it’s a favorite for making round, symmetrical masterpieces. Plus, it gives woodworkers the freedom to shape their wood with creativity and precision.

| Common Applications | Advantages |

|---|---|

| Salad bowls | High precision |

| Decorative platters | Symmetrical designs |

| Wooden sculptures | Creative flexibility |

A wood lathe faceplate is like a superhero’s utility belt—handy and highly versatile! With it, you can create art, bring elegance to your dinner table, or simply pull a “Wow!” from your guests. So, grab that faceplate, twirl some wood, and let your imagination run wild!

Setting Up Your Lathe for Faceplate Turning

Properly mounting the faceplate. Aligning and securing the workpiece.When you’re ready to work with a wood lathe, start with the faceplate. Make sure it’s properly mounted. Tighten it, so it doesn’t wobble. Next, align the workpiece correctly on the faceplate. Secure it tightly using screws or clamps. This keeps everything in place while turning. Follow these steps to avoid slips and enjoy a smooth crafting experience.

How do you align the workpiece on a lathe?

Use a center finder tool to locate the wood’s center. Once centered, tighten the piece onto the faceplate. Always double-check the alignment to ensure even weight distribution. Proper alignment helps in achieving a balanced turn.- Locate the center of the wood.

- Secure the wood firmly.

- Ensure the weight is evenly distributed.

Techniques for Effective Faceplate Turning

Stepbystep guide to faceplate turning techniques. Tips for maintaining control and precision.Faceplate turning can be fun and easy. Follow these steps to get started:

- Securely attach your wood piece to the faceplate.

- Use a tool rest and keep tools sharp for smooth cuts.

- Start at a slow speed; increase gradually.

- Make even, gentle cuts with a steady hand.

Here are some tips:

- Keep your grip firm to maintain control.

- Stand in a balanced position for stability.

- Regularly check your progress to ensure precision.

How do I choose the right faceplate for turning?

Select a faceplate that matches your wood size and type. It should fit well onto your lathe. Using the right size helps in keeping the wood stable during turning.

Using these techniques can make your work better. As woodworker Frank Howarth says, “Precision is key to a perfect turn.” Remember, practice makes perfect!

Safety Precautions in Faceplate Turning

Essential safety equipment and guidelines. Common hazards and how to avoid them.Faceplate turning on a wood lathe can be fun, but you should gear up like a knight! A helmet isn’t required, but a face shield is a must. Ear plugs will block the noise and keep you happy. Remember to keep your sleeves tight or your shirt might try woodturning all by itself. Tools should be sharp—no one likes a lazy chisel! Make sure the wood is securely fastened, or it will fly like a boomerang.

Here’s a quick guide:

| Equipment | Purpose |

|---|---|

| Face Shield | Protects eyes and face |

| Ear Plugs | Reduces noise |

| Dust Mask | Keeps lungs happy |

| Tight Clothing | Prevents entanglement |

Common hazards include flying wood pieces and loud noise. Secure the piece tightly to avoid unexpected flying objects. A dull tool might chat with your nerves, so keep them sharp! Never rush; remember, slow and steady wins the race. Now, stay safe and turn that wood into something amazing!

Creative Projects Using Faceplate Turning

Inspiring ideas for wood lathe projects. Personalizing and finishing your work.Turning wood on a lathe isn’t just about making bowls and plates; it’s an art. With a faceplate, you can create cool projects like clocks, mirrors, or even giant wooden doughnuts—although these aren’t edible! The idea is to let your imagination lead the way while also adding personal touches. To finish your project, some sanding and polishing will make it shine. Adding colors or using wood stains can make your designs stand out.

| Project Idea | Personal Touch |

|---|---|

| Wall Clock | Engrave family names |

| Wooden Bowl | Paint quirky designs |

| Mirror Frame | Add custom carvings |

Whether it’s personalizing items or using unique finishes, the outcome is uniquely yours. As the saying goes, “Every piece of wood has a story”. So get turning, and let your projects tell yours!

Maintenance and Care for Your Lathe and Tools

Routine maintenance tips for longevity. Proper cleaning and storage practices.Maintenance and Care for Your Lathe and Tools

Keeping your lathe and tools in top shape is key for both safety and performance. Here are some simple steps:

- Check the alignment often. This keeps projects smooth and accurate.

- Wipe surfaces every week. Dust and wood shavings can affect your tools.

- Use a soft cloth for cleaning. Hard brushes might scratch the surface.

- Apply oil to moving parts. This reduces wear and tear.

Store tools in a dry, cool place. Moisture can cause rust. A proper cover protects from dust.

Why is tool maintenance important?

Tool maintenance is important because it ensures safety, improves tool life, and maintains the quality of work. Proper care leads to better and more precise projects.

“Good tools, good work” goes a wise saying. This highlights the direct link between tool condition and output quality. Proper tool care isn’t just about longevity; it also makes working with the lathe more enjoyable, and predictable projects improve what you make.

Troubleshooting Common Faceplate Turning Issues

Identifying and resolving common problems. When to seek professional assistance.When your wood lathe faceplate isn’t working right, it can be frustrating. Some common problems include the wood not sticking to the faceplate or the tool making strange noises. To fix these issues:

- Check if the wood is securely attached.

- Ensure that the faceplate is not wobbly.

- Listen for unusual sounds while turning.

- Adjust speed settings if needed.

If these basic fixes don’t work, it might be time to call in the experts. They can help ensure your tool is safe to use.

What causes wood not to stay on the faceplate?

Incorrect mounting or a dirty surface can cause wood to slip. Clean the faceplate and use proper screws to keep wood steady.

Why does my wood lathe make noise?

If your lathe makes noise, it might mean there’s a loose part or uneven wood grain. Regular maintenance can help prevent this.

Expert Tips and Advanced Techniques

Techniques from seasoned woodworkers. Exploring advanced faceplate turning methods.Imagine crafting a masterpiece using a wood lathe; it could be thrilling! Seasoned woodworkers often have techniques that seem like magic. One nifty trick involves ensuring your faceplate is centered and secure. A misaligned faceplate could make your project dance away—a comedy not found in most workshops! For faceplate turning, using the right speed is crucial. As an expert once joked, “Turn it too fast, and you’ll start a new career in flying splinters!” But seriously, balancing the lathe speed keeps your work steady and your nerves intact.

When exploring advanced methods, understanding the wood’s grain direction can make or break your project. A fun fact: Working against the grain is not only a saying but also a recipe for disaster in woodworking! So, what’s the expert secret? Respect the grain!

| Tip | Description |

|---|---|

| Centering the Faceplate | Ensure even weight distribution to prevent wobbling. |

| Correct Speed | Adjust speed based on wood type to avoid mishaps. |

| Grain Direction | Always work with the grain for a smoother finish. |

Curious minds often ask, “Why is grain direction so important?” The answer is simple. It affects the smoothness and longevity of your work. So, remember these tips to avoid turning your workshops into comedy clubs!

Conclusion

Wood lathe faceplate turning is fun and creative. It helps you make amazing round objects from wood. Remember to choose the right wood and secure it properly. Always wear safety gear and take your time. Now, try your own faceplate project, or read more to learn new techniques and become even better!FAQs

What Are The Key Safety Precautions To Consider When Using A Faceplate On A Wood Lathe For Turning Projects?When using a faceplate on a wood lathe, wear safety goggles to protect your eyes. Make sure the wood piece is securely attached to the faceplate. Keep your hands and fingers away from the spinning wood. Tie up long hair and avoid loose clothing to prevent accidents. Always stand to the side when turning on the lathe.

How Do You Properly Mount A Wooden Blank Onto A Faceplate For Secure Turning On A Lathe?First, find the center of your wooden piece, which we call a blank. Then, attach the blank to the faceplate using screws. Make sure the screws are tight so the wood doesn’t move. Finally, fix the faceplate onto the lathe securely. Now, you’re ready to turn the wood safely.

What Are The Advantages And Disadvantages Of Using A Faceplate Compared To A Chuck For Woodturning?Using a faceplate for woodturning is great because it holds wood very securely. It helps when you’re shaping a bowl or a large piece. However, it’s a bit tricky since you have to screw the wood on tightly, which takes time. A chuck is faster to use because it grips the wood with a twist, but it might not be as strong for big pieces.

How Can You Prevent Wood From Cracking Or Coming Loose When Using A Faceplate On A Wood Lathe?To keep the wood from cracking on a wood lathe, tighten the faceplate screws firmly. Use screws that are the right size for the wood. Make sure the wood is dry and without knots. Work slowly and check that the wood is secure often.

What Types Of Projects Or Shapes Are Best Suited For Faceplate Turning As Opposed To Other Wood Lathe Techniques?Faceplate turning is great for making flat or wide items. We can use it to make bowls, platters, and trays. It’s perfect for projects that need a large surface. Faceplate turning helps us shape wood pieces that are more open and curved. This makes our projects sturdy and smooth!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Safety Precautions To Consider When Using A Faceplate On A Wood Lathe For Turning Projects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a faceplate on a wood lathe, wear safety goggles to protect your eyes. Make sure the wood piece is securely attached to the faceplate. Keep your hands and fingers away from the spinning wood. Tie up long hair and avoid loose clothing to prevent accidents. Always stand to the side when turning on the lathe.”}},{“@type”: “Question”,”name”: “How Do You Properly Mount A Wooden Blank Onto A Faceplate For Secure Turning On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “First, find the center of your wooden piece, which we call a blank. Then, attach the blank to the faceplate using screws. Make sure the screws are tight so the wood doesn’t move. Finally, fix the faceplate onto the lathe securely. Now, you’re ready to turn the wood safely.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using A Faceplate Compared To A Chuck For Woodturning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a faceplate for woodturning is great because it holds wood very securely. It helps when you’re shaping a bowl or a large piece. However, it’s a bit tricky since you have to screw the wood on tightly, which takes time. A chuck is faster to use because it grips the wood with a twist, but it might not be as strong for big pieces.”}},{“@type”: “Question”,”name”: “How Can You Prevent Wood From Cracking Or Coming Loose When Using A Faceplate On A Wood Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the wood from cracking on a wood lathe, tighten the faceplate screws firmly. Use screws that are the right size for the wood. Make sure the wood is dry and without knots. Work slowly and check that the wood is secure often.”}},{“@type”: “Question”,”name”: “What Types Of Projects Or Shapes Are Best Suited For Faceplate Turning As Opposed To Other Wood Lathe Techniques?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Faceplate turning is great for making flat or wide items. We can use it to make bowls, platters, and trays. It’s perfect for projects that need a large surface. Faceplate turning helps us shape wood pieces that are more open and curved. This makes our projects sturdy and smooth!”}}]}