Proven wood lathe jig setup: Essential Guide. Master jig setups on your wood lathe with this beginner-friendly guide, ensuring precision, safety, and great results for all your turning projects.

Turning on a wood lathe opens up a world of creative possibilities, from crafting beautiful bowls to intricate spindle work. But to achieve those perfect shapes and finishes, you often need specialized tools and techniques. That’s where wood lathe jigs come in! They’re your secret weapon for repeatability, accuracy, and safety. Setting them up might seem a bit daunting at first, but once you understand the basics, it’s like any other tool – with a little practice, you’ll be using them like a pro. This guide will walk you through the essential steps to set up your wood lathe jigs with confidence. Let’s get started!

Why Wood Lathe Jigs Are a Beginner’s Best Friend

As a fellow tool enthusiast and lifelong maker, I’ve seen countless beginners struggle with achieving consistent results on the wood lathe. Often, the issue isn’t a lack of skill, but rather the absence of reliable jigs. Jigs are designed to hold your work or your tools in precise positions, eliminating guesswork and reducing the chance of errors. For newcomers, this means fewer frustrating mistakes and more satisfying projects. Think of them as helpful assistants that guide your hands and ensure every cut is exactly where you want it. This is especially crucial when you’re learning something like wood lathe tool sharpening jig setup, where precision directly impacts the performance of your cutting tools.

Understanding Your Wood Lathe Jigs

Before we dive into setup, let’s quickly identify some common jigs you’ll encounter. Each serves a specific purpose, and knowing what each one does is the first step to using it effectively.

Common Wood Lathe Jigs:

- Tool Sharpening Jigs: Essential for keeping your turning tools razor-sharp. These jigs hold your chisels and gouges at the correct angles for grinding or honing.

- Bowl Jigs (Faceplate Rings, Chuck Jaws): Used for securely mounting and turning bowls, particularly when working with larger or irregularly shaped pieces.

- Spindle Turning Jigs: Assist in creating identical repeated spindle elements for furniture legs or other decorative pieces.

- Drilling Jigs: Allow you to accurately drill holes in the center of your turned pieces, like for lamps or hollow vessels.

- hollowing Jigs: Specifically designed to help you safely and accurately hollow out bowls and other hollow forms.

For this guide, we’ll focus on the fundamental setup principles that apply to most jigs, with a special emphasis on tool sharpening jigs, as they are universally important for anyone using a wood lathe.

The Foundation: Safety First!

Before even thinking about setting up a jig, let’s talk safety. My number one priority as Daniel Bates of Lathe Hub is always making sure you’re safe. Working with rotating machinery demands respect and attention. Always:

- Disconnect Power: Always turn off and unplug your lathe before making any adjustments or setting up jigs.

- Wear Safety Gear: Safety glasses or a face shield are non-negotiable. A dust mask is also a good idea.

- Secure Your Workpiece: Ensure your workpiece, and any jig attached to it, is firmly secured. Loose items can become projectiles.

- Understand the Tool: Read the manual for both your lathe and your specific jig. Know how it operates.

- Clear Your Workspace: Keep your lathe area tidy. Remove any clutter that could get caught or cause a trip hazard.

Safety isn’t just a suggestion; it’s the bedrock of good woodworking and machining. A moment of carelessness can lead to serious injury.

Essential Tools for Jig Setup

While jigs themselves are the star, a few common tools will make the setup process much smoother and more accurate. You likely already have most of these in your workshop:

Tool Checklist:

- Combination Square or Speed Square: For ensuring 90-degree angles and making quick measurements.

- Measuring Tape or Ruler: For precise length and distance checks.

- Wrenches/Allen Keys: To tighten bolts and adjustments on your jig and lathe.

- Center Punch: For marking precise locations if drilling or starting a project.

- Level: To ensure your jig is mounted perfectly horizontal or vertical where necessary.

- Calipers (Optional but helpful): For more precise measurements of diameters and thicknesses.

Step-by-Step: Setting Up a Tool Sharpening Jig for Your Wood Lathe

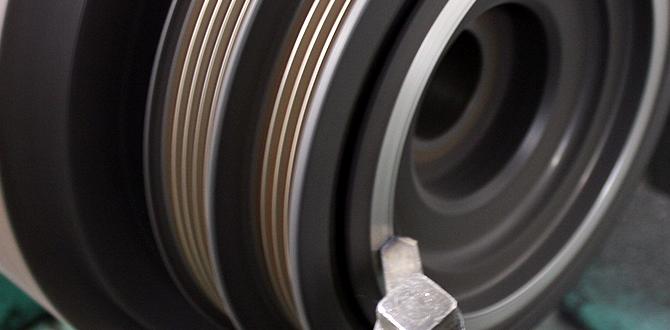

Let’s walk through setting up a common type of tool sharpening jig. These can vary, but the core principles of alignment and setting the correct angle are universal. Many jigs utilize a platform or arm that travels across your tool rest, allowing you to present your tool to the grinding wheel or sharpening stone at a consistent angle.

Step 1: Prepare Your Grinding Station

First, ensure your grinder is set up safely. This usually means having the grinding wheels at a comfortable height, and the tool rests adjusted so there’s a small gap between the rest and the wheel (check your grinder’s manual, typically around 1/8 inch or 3mm). If you’re using a jig, it will likely attach to or rest on your grinder’s tool rest. Make sure the tool rest is securely clamped and adjusted correctly.

Step 2: Mount the Jig to the Tool Rest

Most sharpening jigs are designed to slide onto or clamp securely onto the tool rest of your grinder. Carefully place the jig onto the tool rest. Ensure it sits flat and stable. Tighten any knobs or bolts that secure the jig to the tool rest. Give it a gentle shake to confirm it’s firmly in place. A wobbly jig leads to inconsistent sharpening.

Step 3: Understand the Jig’s Adjustments

Take a moment to familiarize yourself with all the adjustment mechanisms on your jig. You’ll typically find:

- Angle Adjustment: This is the most critical part. It allows you to set the bevel angle of your tool. It might be a dial, a pivot with measurement markings, or a simple sliding scale.

- Depth Adjustment: Controls how far the tool edge contacts the grinding wheel.

- Centering/Positioning: Some jigs allow you to slide them left or right on the tool rest or adjust their height to align with the center of the grinding wheel.

Step 4: Set the Primary Bevel Angle

This is where your research comes in. Different tools (skew chisels, gouges, scrapers) require different bevel angles for optimal cutting. For a general woodworking chisel or gouge, a primary bevel of around 30-45 degrees is common for general-purpose work. For more specialized tasks, you might need different angles.

Use your jig’s angle adjustment mechanism to set your desired angle. Many jigs have indicator marks. For extreme accuracy, you might use a digital angle finder or a protractor, but start with the jig’s built-in scale. Ensure the adjustment is locked down firmly.

Step 5: Position the Tool and Set Depth

Place your tool (e.g., a bowl gouge) into the jig. The V-shaped groove or clamp on most jigs is designed to hold the tool securely. Initially, set the jig so that the tool’s heel (the rear part of the bevel) just touches the grinding wheel when the wheel is stationary. Then, adjust the depth of cut. A common starting point is to set the jig so the very cutting edge of the tool is presented to the wheel.

Tip: For a fresh grind and to avoid overheating the tool, start with a light pass. You can always remove more metal. A good rule of thumb is to grind in short bursts and periodically dip your tool in water to cool it down. Overheating will ruin the temper of your steel.

Step 6: Perform a Test Grind/Hone

With the power still off, move the tool back and forth along the jig to see how it travels. Ensure it moves smoothly and consistently across the entire length of the bevel you intend to sharpen. Then, turn on the grinder/sandpaper. Make a light pass with your tool against the jig. Turn off the grinder and inspect the edge. You should see a faint, even burr forming along the cutting edge. If the burr is inconsistent, uneven, or non-existent, re-check your jig setup, angle, and tool presentation.

Step 7: Fine-Tune and Sharpen

Once you’re happy with the initial setup and the evenness of the burr, you can proceed with sharpening. Grind in short bursts, alternating sides if sharpening both bevels. Keep the tool cool. After grinding, you’ll typically move to a honing stage (using stones or strops) to refine the edge. Many jigs can also be adapted for honing, or you can use them to set the angle on your honing guides.

Beyond Sharpening: Setting Up Other Essential Jigs

While sharpening jigs are fundamental, mastering other jig setups will significantly expand what you can do with your wood lathe.

Drilling Jigs for Perfect Center Holes

A good drilling jig, often mounted to the lathe’s bed or tool rest, ensures your drill bit enters the workpiece precisely at its center. This is vital for projects like turning hollow forms, lamps, or pen blanks.

- Setup Basics: The jig usually has a mechanism to hold your drill bit and a guide that aligns with the lathe’s center line. You’ll need to align the jig’s guide perfectly with the headstock and tailstock center line. A laser alignment tool can be extremely helpful here.

- Key Considerations: Ensure the drill bit spins true and that the jig allows for easy feeding of the bit into the rotating workpiece.

For accurate alignment guides, resources like the Wood Magazine article on drilling wood lathe work offer excellent visual aids and tips.

Faceplate and Chuck Jaw Setup for Bowl Turning

These aren’t strictly “jigs” in the same way, but they are critical for securely mounting work for bowl turning and require careful setup.

- Faceplate Rings: Used for larger projects where direct mounting to a faceplate is beneficial. Ensure the faceplate is securely screwed to a solid piece of timber, which is then screwed to your faceplate. Always ensure all screws are fully countersunk and the wood is sound.

- Chuck Jaws: Modern wood lathe chucks with interchangeable jaws are incredibly versatile. When mounting work, ensure the jaws are properly seated and tightened securely around your workpiece. Many chucks have alignment indicators. Always read your chuck manufacturer’s instructions.

The importance of properly securing bowls cannot be overstated, as a chucked bowl at speed can be very dangerous if it separates from the chuck. For detailed information on chuck safety, refer to resources from organizations like the American Association of Woodturners (AAW Safety Best Practices).

Troubleshooting Common Jig Setup Issues

Even with the best intentions, you might run into a few snags. Here’s how to tackle them:

Problem: Inconsistent Grinding Angle on Tools

- Check: Is the jig securely clamped to the tool rest? Is the tool resting evenly within the jig’s holder? Are the jig’s angle indicators accurate, or is there play in the mechanism?

- Solution: Re-clamp the jig securely. Ensure the tool is seated properly. Use a separate angle gauge for verification.

Problem: Tool Chatters or Jumps During Sharpening

This indicates instability.

- Check: Is the grinder’s tool rest also stable? Is the jig itself wobbling? Are you applying too much pressure?

- Solution: Ensure the grinder’s tool rest is solid and correctly positioned. Double-check the jig’s mounting. Use lighter pressure and short bursts.

Problem: Jig Doesn’t Seem to Align Correctly

This is common with drilling jigs or more complex setups.

- Check: Has the jig been mounted perfectly parallel to the lathe’s bed? Are you using the correct reference points?

- Solution: Use a known straight edge or a laser guide to confirm alignment. Re-read setup instructions and double-check all mounting points.

Maintaining Your Jigs for Longevity and Accuracy

Just like your lathe tools, your jigs deserve a little care. Keeping them clean and in good working order ensures they perform reliably for years to come.

- Clean Regularly: Wipe down jigs after each use to remove dust, metal shavings, or grinding grit. This prevents grit from interfering with adjustments or scratching your tools.

- Lubricate Moving Parts: If your jig has threaded adjustments or pivot points, a light application of oil or wax can keep them moving smoothly and prevent corrosion.

- Inspect for Wear: Periodically check for any signs of significant wear, damage, or bent components. Replace parts if they compromise the jig’s accuracy or safety.

- Secure Storage: Store your jigs in a dry place, preferably in a toolbox or on a shelf where they won’t get damaged.

A Comparison: Jig Setup vs. Freehand Sharpening

Many experienced turners can sharpen their tools freehand, relying on years of feel and practice. However, for beginners, jigs offer distinct advantages:

| Feature | Wood Lathe Jig Setup | Freehand Sharpening |

|---|---|---|

| Precision & Consistency | High. Maintains exact angles. | Variable. Relies heavily on user skill. |

| Learning Curve | Moderate. Requires understanding jig mechanics. | Steep. Takes significant practice to master. |

| Tool Wear | Controlled. Minimal metal removed per sharpening. | Can result in excessive wear if angles are misjudged. |

| Confidence for Beginners | High. Reassuring and forgiving. | Low. Often leads to frustration and dull tools. |

| Speed | Can be faster once set up. | Quick for experienced users, but can be slow if corrections are needed. |

| Cost | Initial investment for the jig itself. | Minimal if using existing bench grinder/stones. |

As you can see, for those starting out, a jig is an invaluable aid. It allows you to focus on learning the correct tool geometry and sharpening principles without the added pressure of holding precise angles by feel alone. This foundation will serve you well, even if you decide to transition to freehand sharpening later.

FAQ: Your Wood Lathe Jig Setup Questions Answered

Q1: How do I know what angle to set my wood lathe tool sharpening jig to?

A1: The correct angle depends on the tool and the type of cut you’ll make. For general-purpose bowl gouges, a primary bevel of 30-45 degrees is common. For scrapers, it might be flatter (around 60 degrees) or even zero degrees if you’re burnishing. Skew chisels have more complex grind angles. Consult your tool manufacturer’s recommendations or woodworking resources for specific angles.

Q2: Can I use the same jig for all my wood lathe tools?

A2: Many sharpening jigs are versatile and can accommodate various tools like gouges, scrapers, and chisels by simply adjusting how the tool is held or presented. However, some highly specialized tools or specific sharpening needs might benefit from a dedicated jig.

Q3: How tight should I make the jig’s clamps?

A3: Tight enough so that the jig is completely secure and doesn’t shift during operation. However, avoid over-tightening, which could strip threads or damage the jig, your tool rest, or the tool itself.

Q4: What if my jig doesn’t seem to give a consistent edge?

A4: This usually points to an issue with the setup. Double-check that the jig is firmly attached to the tool rest, that the tool is seated correctly in the jig, and that all locking mechanisms are engaged. A slightly bent tool rest on your grinder could also be the culprit.

Q5: Do I need to lubricate my jigs?

A5: If your jig has threaded adjustment screws or pivot points, a light application of wax or a dry lubricant can help keep them moving smoothly and prevent rust, especially in humid workshops. Excessive lubrication can attract dust; use sparingly.