Choosing between a wood lathe and a CNC router? For beginners, this decision can seem complex. Both are fantastic tools for creating amazing projects, but they work very differently. This guide breaks down the key differences, helping you pick the right machine for your workshop and your creative goals.

Wood Lathe vs CNC Router: Essential Comparison

Hey there, fellow makers! Daniel Bates here, your guide from Lathe Hub. If you’re stepping into the world of woodworking or metalworking and eyeing up some cool machinery, you’ve probably stumbled upon wood lathes and CNC routers. They both let you shape materials, but in ways that are almost opposite. One relies on your skilled hands and a spinning piece of wood, while the other uses computer power to guide a cutting tool. Which one is right for you? That’s what we’re here to figure out, step-by-step.

For years, I’ve worked with all sorts of tools in my workshop, from classic manual lathes to the latest electronic marvels. I know how it feels to be at the start, wondering if you’re making the right investment. My goal is to make these powerful tools accessible and understandable. We’ll look at what each machine offers, who it’s best for, and what kind of projects you can tackle.

What is a Wood Lathe?

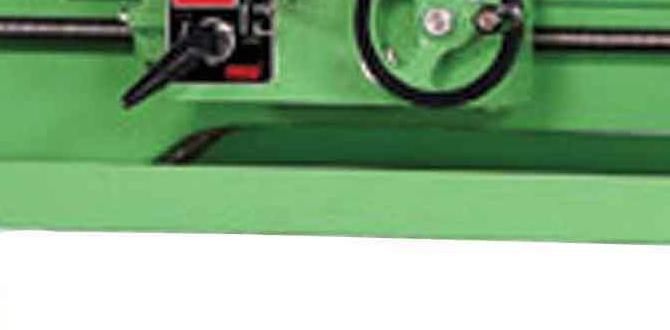

At its heart, a wood lathe is a woodworking machine that spins a piece of wood. You then use sharp tools to shave, cut, and shape the wood as it turns. Think of turning a raw log into a beautiful table leg, a decorative bowl, or a spindle. It’s a very hands-on process that requires skill, patience, and a good feel for the material.

The wood is held between two points: a “headstock” that drives the wood and a “tailstock” that supports the other end. As the headstock spins the wood at a set speed, you use chisels and gouges to carefully remove material. The result is often a symmetrical, rounded shape. Fine motor skills and practice are key to mastering a wood lathe.

How a Wood Lathe Works

1. Mounting the Workpiece: The wood is secured between the headstock spindle (often with a spur drive) and the tailstock center. For faceplate work, it can be screwed directly onto a faceplate attached to the headstock spindle.

2. Spindle Speed: The headstock motor controls the rotational speed (RPM) of the workpiece. Slower speeds are good for rough turning or larger pieces, while faster speeds are better for finishing finer details.

3. Using Tools: You hold specialized wood turning chisels and gouges against a tool rest. As the wood spins, you carefully present the cutting edge of your tool to the wood to remove material. Different tools are used for different tasks, like roughing out shapes, hollowing bowls, or creating fine details.

4. Shaping: By controlling the angle and pressure of the tool against the spinning wood, you gradually refine the shape until it matches your design. This often involves a series of steps, from rough shaping to sanding and finishing.

Pros of a Wood Lathe

- Hands-on Skill Development: Excellent for building tactile skills and developing an intuitive feel for woodworking.

- Simplicity and Affordability: Generally less complex and more affordable upfront than CNC routers.

- Immediate Results: You can often see your projects take shape very quickly as you turn.

- Satisfying Craftsmanship: Offers a deep sense of accomplishment from creating something with your own hands.

- Lower Tooling Costs: Woodworking chisels and gouges are typically less expensive than CNC router bits.

Cons of a Wood Lathe

- Requires Skill and Practice: Mastering the techniques takes time and dedication.

- Limited to Rotational Shapes: Primarily suited for round or symmetrical objects.

- Safety Concerns: Wood chips and spinning pieces can be hazardous if safety precautions aren’t followed strictly.

- Manual Effort: Can be physically demanding, especially for larger or more complex projects.

- Difficult for Identical Duplicates: Extremely hard to make two identical pieces without extensive practice and templates.

What is a CNC Router?

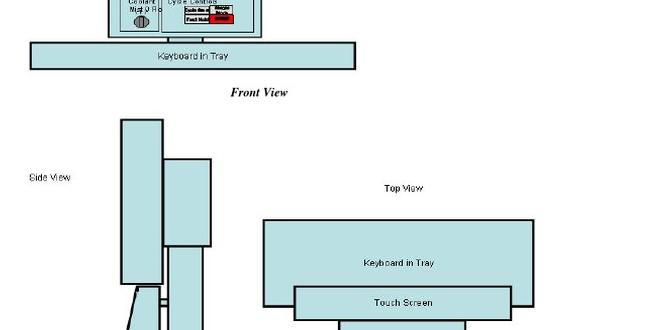

A CNC (Computer Numerical Control) router is a versatile cutting machine. Instead of your hands guiding the tool, computer commands direct a high-speed spindle that holds a cutting bit. This spindle moves in multiple directions (usually X, Y, and Z axes) across a flat bed, cutting away material from a stationary workpiece. It’s like a robotic sculptor, capable of incredibly precise and complex designs.

CNC routers can work with wood, but also many other materials like plastics, foams, and even soft metals. Because the computer controls the movement, you can repeat designs exactly, create intricate patterns, and achieve a level of accuracy that’s very difficult to attain by hand. You design your project on a computer using CAD (Computer-Aided Design) software, then use CAM (Computer-Aided Manufacturing) software to generate the toolpaths.

How a CNC Router Works

1. Design Creation: You create your design in CAD software (e.g., fusion 360, SketchUp, Vectric VCarve). This is a digital blueprint of what you want to cut.

2. Toolpath Generation: CAM software translates your design into a series of machine instructions (G-code). This tells the CNC router exactly where to move, how fast, and when to engage the cutting tool.

3. Material Setup: The workpiece is secured to the bed of the CNC router, typically using clamps, screws, or a vacuum table. The correct cutting bit is installed in the spindle.

4. Execution: You load the G-code into the CNC controller. The machine then precisely moves the spindle and router bit according to the program, cutting the material away to create your design.

5. Finishing: Once the cutting is complete, you remove the workpiece. Depending on the complexity, some manual finishing (like sanding) might still be required.

Pros of a CNC Router

- Precision and Accuracy: Capable of incredibly detailed and repeatable cuts.

- Versatility: Can cut complex shapes, intricate details, inlay work, and 3D carvings.

- Repeatability: Perfect for making multiple identical items with ease.

- Automation: Once programmed, it can run with minimal supervision, freeing you up for other tasks.

- Material Range: Can work with a wide variety of materials beyond just wood.

Cons of a CNC Router

- Higher Initial Cost: CNC routers are typically more expensive than wood lathes.

- Learning Curve: Requires learning CAD/CAM software and understanding machine operation.

- Dust Management: Produces a lot of fine dust that needs effective collection systems.

- Tooling Costs: CNC bits can be expensive and wear out, requiring replacement.

- Less Tactile Experience: Can feel less hands-on and more like operating a computer.

Wood Lathe vs CNC Router: Key Differences

The most fundamental difference lies in how material is removed and how the user interacts with the process. A wood lathe uses a spinning workpiece and static cutting tools guided by hand. A CNC router uses a static workpiece and a moving cutting tool guided by computer code.

| Feature | Wood Lathe | CNC Router |

|---|---|---|

| Primary Operation | Spinning workpiece, hand-held tools | Stationary workpiece, computer-guided tool |

| Typical Projects | Bowls, spindles, table legs, pens, ornamental turning | Signs, intricate inlays, cabinet doors, 3D carvings, puzzle boxes, custom parts |

| Shape Capabilities | Primarily symmetrical and round | Highly complex 2D and 3D shapes |

| Precision | Dependent on user skill | High, computer-controlled accuracy |

| Repeatability | Very difficult to achieve | Excellent; perfect for duplicates |

| Learning Curve | Moderate (tool control techniques) | Steeper (CAD/CAM software, machine logic) |

| Initial Cost | Lower to moderate | Moderate to high |

| Material Versatility | Primarily wood | Wood, plastics, foam, soft metals, composites |

| Hands-on Experience | Very high | Moderate (setting up, supervising) |

Who Should Choose a Wood Lathe?

A wood lathe is an excellent choice if you’re drawn to the tactile, hands-on nature of woodworking. It’s for the hobbyist who loves the feel of wood and enjoys the process of shaping it with their own hands. If your interest lies in creating classic turned items like elegant bowls, sturdy table legs, decorative spindles for furniture, or even small items like pens and bottle stoppers, a wood lathe is your go-to machine.

It’s also for those who want to develop a fundamental woodworking skill. Learning to use a wood lathe teaches you about wood grain, tool control, and the subtle art of creating smooth, flowing curves. If you’re on a tighter budget for your first major workshop tool, a good quality wood lathe can often be acquired at a lower price point than a capable CNC router. Plus, the immediate feedback you get from turning is incredibly rewarding and helps build confidence quickly.

Ideal Wood Lathe Projects for Beginners:

- Simple turned pens and pencils.

- Basic bowls and platters.

- Straight spindles for small projects.

- Candlestick holders.

- Wooden scoops or spatulas.

Who Should Choose a CNC Router?

A CNC router is perfect for those who envision creating designs with intricate details, sharp lines, and consistent repetition. If you find yourself sketching complex patterns, wanting to create stencils, inlaying different materials, or designing cabinet doors with unique panel profiles, a CNC router will be your best friend. It’s for the tinkerer who loves problem-solving with technology and enjoys the precision that digital design offers.

If you have a business idea that requires making many identical parts, or if you’re an educator looking to introduce students to advanced manufacturing concepts, a CNC router is invaluable. While the initial learning curve – mastering CAD/CAM software and understanding the machine’s operation – can be steeper, the payoff is immense. You can bring incredibly complex digital designs to life with remarkable accuracy. It opens up a world of possibilities for custom furniture, intricate signage, puzzles, circuit boards, and even prototypes for other inventions. For a deeper dive into CNC basics, resources like the National Institute of Standards and Technology (NIST) offer foundational information on how CNC technology works.

Ideal CNC Router Projects for Beginners:

- Custom signs with lettering and graphics.

- Jigs and fixtures for other workshops.

- Simple 2D cutouts and puzzles.

- Engraved plaques.

- Basic cabinet door designs.

Making the Choice: Key Considerations

When deciding between a wood lathe and a CNC router, consider your passion, your budget, and your workspace. What kind of projects do you dream of making? Do you enjoy the physical craft of shaping wood by hand, or do you get excited by digital design and automated precision?

Your available space is also a factor. Wood lathes can be more compact, but keep in mind the need for good dust collection regardless of your choice. Both machines require clear space around them for safe operation. And finally, your budget will play a significant role. Entry-level wood lathes are generally more affordable than entry-level CNC routers. However, consider the long-term value and the types of projects you’ll be able to accomplish with each.

Safety First: Always!

No matter which machine you choose, safety is paramount. Always wear appropriate safety gear. For wood turning, this means eye protection, a dust mask, and often a face shield. Ensure your tools are sharp and properly handled. Never wear loose clothing or jewelry that could get caught. For CNC routers, eye protection and dust masks are essential. Be aware of the moving parts and ensure the workpiece is securely fixtured before starting any cut. Understanding the emergency stop procedures for your specific machine is critical. For detailed safety guidelines specific to woodworking tools, check out resources from organizations like the Wood Magazine or the Woodworkers Alliance for Safer Machines (W.A.S.M.).

Frequently Asked Questions (FAQ)

Q1: Can a wood lathe cut shapes like a CNC router?

A1: No, a wood lathe is primarily designed for creating symmetrical, round shapes by shaving material off a spinning workpiece with hand-held tools. A CNC router, on the other hand, can cut highly complex, non-symmetrical 2D and 3D shapes and intricate details using computer-controlled movements.

Q2: Is a CNC router difficult to learn?

A2: Yes, it does have a steeper learning curve than a wood lathe. You’ll need to learn CAD (design) and CAM (toolpath generation) software, understand G-code, and get comfortable with machine operation and maintenance. However, with dedication, it’s very achievable.

Q3: Which machine is better for making multiple identical items?

A3: A CNC router is far superior for making multiple identical items. Once programmed, it can replicate designs with high accuracy repeatedly. Doing this by hand on a wood lathe requires exceptional skill and extreme patience, and even then, slight variations are likely.

Q4: What is the typical cost difference between a wood lathe and a CNC router?

A4: Generally, entry-level wood lathes are more affordable than entry-level CNC routers. You can find basic wood lathes for a few hundred dollars, while capable hobbyist CNC routers often start in the low thousands. High-end machines for both categories can be significantly more expensive.

Q5: Can I use my CNC router to make wood-turned objects?

A5: No, a CNC router is not designed for wood turning in the same way a wood lathe is. While a CNC can carve shapes that mimic turned forms on a flat surface, it cannot create the hollow or fully rounded profiles that a spinning workpiece on a lathe can produce.

Q6: Which machine produces more dust?

A6: Both can produce significant dust. Wood lathes create chips and sawdust from the turning process. CNC routers, especially when cutting wood, create very fine dust that requires robust dust collection systems. Effective dust management is crucial for both.

Q7: If I want to make a wooden bowl, should I get a lathe or a router?

A7: For making a traditional wooden bowl, a wood lathe is the correct tool. While a CNC router can carve out a bowl shape from a block of wood, it won’t have the smooth, flowing curves and often the thin walls achievable with a lathe from a blank mounted between centers or on a faceplate.

Conclusion: Your Workshop, Your Choice

So, there you have it! The wood lathe and the CNC router are both incredible tools, but they serve different purposes and appeal to different makers. If you crave the direct, tactile experience of shaping wood with your own hands, and enjoy creating beautiful, symmetrical forms, a wood lathe is likely your path forward. It’s a classic skill that offers immense satisfaction.

On the other hand, if your imagination is filled with intricate designs, complex patterns, and the desire for perfect repeatability through precision engineering, a CNC router will unlock a world of creative potential. It’s a bridge between your digital vision and a physical creation.

Don’t feel pressured to pick the “better” machine; instead, focus on the one that best aligns with your personal interests, projects, and learning style. Many experienced makers even have both! Whichever you choose, remember that practice, patience, and a commitment to safety will lead you to amazing results. Happy making, and I’ll see you in the workshop!