Quick Summary: For working with bronze, a 3-flute end mill is generally the superior choice over a 4-flute. Its design allows for better chip clearance, reducing clogging and heat buildup, which is crucial for this softer, “gummy” metal, leading to cleaner cuts and extended tool life.

Choosing the right cutting tool can feel like a puzzle, especially when you’re just starting out in the workshop. You’ve got your project in mind, maybe something with that beautiful, warm glow of bronze, but then you hit a snag: which end mill should you use? You’ve seen them around – some with more teeth, some with fewer. This often brings up the question: “4 flute vs. 3 flute: which is best for bronze?” It’s a valid question, and one that can make a real difference in your results. Don’t worry, though! We’re going to break down exactly why this choice matters and which one will make your bronze projects sing. We’ll cover everything you need to know so you can confidently grab the right tool and get to making.

Demystifying End Mills: Flutes and Their Function

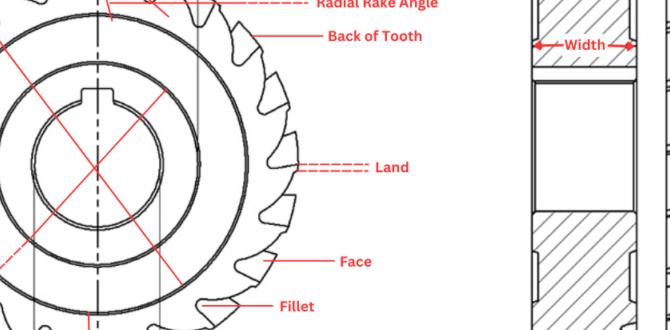

Before we dive into the specifics of 3-flute versus 4-flute end mills for bronze, let’s quickly cover what “flutes” actually are. Think of flutes as the spiral grooves machined into the cutting head of an end mill. Their main jobs are twofold: they act as channels to remove material (chips) from the workpiece, and they form the cutting edges that actually slice into the material. The number of flutes tells you how many of these cutting edges are present on the tool.

More flutes generally mean more cutting edges. This sounds like it would always be better, right? Not necessarily, especially when you’re dealing with different materials like bronze. The number of flutes impacts how much chip material can escape and how much heat the tool can manage. This is where the distinction between 4-flute and 3-flute tools becomes really important.

Understanding Bronze: A Machinists’ Perspective

Bronze is a fascinating alloy, typically made from copper and tin. It’s known for its strength, corrosion resistance, and that distinctive, appealing color. However, from a machining standpoint, bronze can be a bit… challenging. It’s often described as “gummy” or “sticky.” This means it tends to deform rather than chip cleanly, and it can cling to cutting tools. This gummy nature leads to increased friction, which means more heat generated during the machining process. Overheating can cause tool wear, poor surface finish, and even damage to your workpiece. So, when selecting an end mill, we need a tool that can handle these characteristics effectively.

4 Flute End Mill: What It’s Good For

A 4-flute end mill has four cutting edges. Because it has more cutting edges, it can generally take a heavier depth of cut and produce a smoother surface finish in many materials. This is because the load is distributed across more edges, and the chip load (the amount of material removed by each tooth) can be smaller. This makes 4-flute end mills excellent for finishing operations where a smooth surface is paramount, and for machining tougher metals like steel or stainless steel where efficient chip evacuation isn’t quite as critical as with softer metals. Their higher number of flutes also means they can often run at slightly higher surface speeds in certain applications.

Key characteristics of 4-flute end mills:

- More cutting edges for a smoother finish.

- Better suited for harder materials like steel.

- Can handle heavier depths of cut in some materials.

- More prone to chip clogging in “gummy” materials.

3 Flute End Mill: The Workhorse for Softer Metals

Now, let’s talk about the 3-flute end mill. With three cutting edges, it leaves more space between the flutes compared to a 4-flute of the same size. This increased space is precisely what gives it an advantage when machining softer, “gummy” materials like aluminum and, crucially for us, bronze. The larger flute gullets (the space between the cutting edges) allow for much better chip evacuation. When you’re cutting bronze, chips can be long and stringy. If the flutes can’t clear these chips quickly, they can re-cut, overheat, and clog the tool. A 3-flute end mill is designed to handle this by providing more room for those chips to escape.

Additionally, with fewer cutting edges, the chip load per tooth can be increased slightly, or conversely, the heat generated per cutting edge is spread out over fewer edges, which can sometimes lead to less overall heat buildup in very gummy materials compared to a 4-flute. This makes 3-flute end mills a fantastic choice for slotting, pocketing, and general milling operations in softer metals.

Key characteristics of 3-flute end mills:

- Increased chip clearance, ideal for gummy materials.

- Reduced risk of chip clogging and overheating.

- Excellent for slotting and pocketing.

- Good balance between material removal and finish.

4 Flute vs. 3 Flute for Bronze: The Showdown

So, when it comes to the specific question of “4 flute end mill vs. 3 flute end mill for bronze,” the answer leans heavily towards the 3-flute end mill. Let’s break down why:

- Chip Evacuation: Bronze’s tendency to be “gummy” means it produces longer, stringy chips. A 3-flute end mill has larger flute gaps, allowing these chips to exit the cutting zone more freely. This prevents the material from packing into the flutes, which is a major cause of tool breakage and poor surface finish. A 4-flute end mill’s tighter flutes would struggle to clear these chips, leading to rapid clogging and overheating.

- Heat Management: Because bronze generates more heat due to friction, efficient chip evacuation is key to carrying that heat away. By clearing chips effectively, the 3-flute end mill helps keep the cutting edge cooler. Overheating is the enemy of tool life and workpiece quality, and for bronze, a 3-flute tool is better equipped to combat it.

- Cutting Load: While a 4-flute might handle a higher overall load in some materials, the “gummy” nature of bronze can make the cutting forces unpredictable. A 3-flute end mill can often achieve a good chip load per tooth without excessive force, reducing the strain on both the tool and your machine.

- Surface Finish: While 4-flute end mills are often praised for finishing, a sharp 3-flute end mill, when used correctly with appropriate speeds and feeds, can produce an excellent surface finish on bronze. The key is to avoid the issues that arise from chip packing, which a 4-flute is more prone to in this material.

Think of it this way: you’re trying to clear a path through a sticky, crowded room. A path with fewer people (flutes, allowing more space) will be much easier to navigate and clear out than a path with many people crammed together, where everyone gets stuck. That’s the difference for bronze.

Choosing the Right Bronze: A Material Guide

Not all “bronze” is created equal. While the general principles for end mill selection hold true throughout the bronze family, understanding specific alloy types can further refine your approach. Here are a few common types and their machining considerations:

- Phosphor Bronze (e.g., C51000, C52100): These are workhorses known for good bearing properties and wear resistance. Phosphor bronzes can be a bit harder than some other bronzes, but they still fall into the “gummy” category. A 3-flute end mill is still the go-to for effective machining here.

- Aluminum Bronze (e.g., C61400, C95400): These alloys offer excellent strength, wear resistance, and corrosion resistance, often rivalling some steels. They can be tougher to machine than tin bronzes and tend to generate more heat. The need for good chip clearance becomes even more critical, reinforcing the choice of a 3-flute end mill. Proper speeds and feeds are vital here.

- Manganese Bronze (e.g., C86500): Often used for high-stress applications like valve stems and gears. These are also quite strong and can be abrasive. Again, a 3-flute end mill provides the best balance for chip evacuation and tool life.

For any bronze alloy, starting with a 3-flute end mill as your primary choice for milling operations like pocketing or slotting is a safe and effective bet. If you’re doing some very light, shallow finishing passes, a 4-flute might be considered in some edge cases, but the risk of clogging often outweighs any perceived benefit.

Materials for End Mills: High-Speed Steel vs. Carbide

Beyond the number of flutes, the material the end mill is made from also plays a significant role in its performance. For machining bronze, you’ll typically encounter two main types:

High-Speed Steel (HSS) End Mills

HSS end mills are a more traditional choice. They are generally less expensive than carbide tools and are quite tough, meaning they can absorb shock well. For softer, “gummy” materials like bronze, HSS can be a good option because its toughness can help prevent chipping. However, HSS has a lower heat resistance than carbide, so maintaining appropriate speeds and feeds to avoid overheating is crucial. If you’re just starting or on a budget, HSS can get the job done, but you might need to run slightly slower.

Carbide (Solid Carbide) End Mills

Solid carbide end mills are made from tungsten carbide, a very hard and wear-resistant material. They can withstand higher cutting speeds and temperatures than HSS, often leading to faster machining times and longer tool life when used correctly. For bronze, carbide end mills, particularly those with a bright (uncoated) finish, are excellent. They maintain their sharpness longer and can handle the heat generated. While they are more expensive upfront, their longevity often makes them more cost-effective in the long run, especially for production work or if you’re frequently milling bronze.

Recommendation for Bronze: For bronze, a solid carbide 3-flute end mill is often considered the gold standard. The combination of excellent chip clearance and the heat resistance of carbide provides the best results for tool life and cut quality. If you are on a tighter budget, a good quality HSS 3-flute end mill will still perform well, but you’ll need to be more mindful of your cutting parameters.

Speeds and Feeds: The Crucial Parameters

Choosing the right end mill is only half the battle. Properly setting your speeds and feeds (how fast the tool spins and how fast it moves into the material) is absolutely critical for success, especially with bronze. Incorrect speeds and feeds are a common source of frustration and tool failure.

General Guidelines for Bronze with a 3-Flute End Mill:

- Surface Speed (SFM): For solid carbide, you might start in the range of 200-400 SFM (Surface Feet per Minute). For HSS, you’ll want to be lower, perhaps 50-150 SFM. These are starting points; always consult tool manufacturer recommendations if available.

- Chip Load per Tooth (IPT): This is the thickness of the chip each flute takes. For a 3-flute end mill in bronze, you might aim for a chip load of 0.001″ to 0.005″ (0.025mm to 0.127mm), depending on the diameter of the end mill. Smaller diameter end mills require smaller chip loads.

- Calculation: Your machine’s controller or a CAM software will use your desired Spindle Speed RPM and the Chip Load per Tooth to calculate the Feed Rate (IPM or mm/min).

Example Calculation (Simplified):

Let’s say you have a 1/4″ diameter carbide 3-flute end mill and you want to run at 300 SFM.

First, convert SFM to RPM:

RPM = (SFM 3.25) / Diameter

RPM = (300 3.25) / 0.25 = 3900 RPM.

Now, let’s choose a chip load of 0.002″ per tooth.

Feed Rate (IPM) = RPM Number of Flutes Chip Load per Tooth

Feed Rate = 3900 3 0.002 = 23.4 IPM.

These are just illustrative numbers. Always consult reliable resources for your specific end mill geometry and material. Machining Doctor is a great online resource for exploring speeds and feeds for various materials and tool types.

Key Takeaway: Start with conservative speeds and feeds, listen to your machine and the cut, and gradually adjust. If you’re getting chatter, poor finishes, or excessive heat, it’s likely an issue with your speeds or feeds.

Table: 3-Flute vs. 4-Flute End Mills for Bronze

To summarize the core differences and their impact on machining bronze, let’s look at this comparison:

| Feature | 3-Flute End Mill | 4-Flute End Mill |

|---|---|---|

| Primary Advantage for Bronze | Superior chip clearance for “gummy” materials. | Smoother finish in less gummy materials. |

| Chip Evacuation | Excellent. Larger gullets allow for easy removal of long chips. | Fair to Poor. Smaller gullets can clog easily with bronze chips. |

| Heat Management | Good, aided by efficient chip evacuation to carry heat away. | Can lead to increased heat buildup due to chip packing. |

| Risk of Clogging | Low. | High. |

| Recommended Operations for Bronze | Slotting, pocketing, general milling, roughing passes. | Generally Avoided for primary milling operations in bronze. May be used for very light finishing passes in specific scenarios. |

| Material Suitability Comparison | Excellent for aluminum, copper, brass, bronze, plastics. | Excellent for steels, stainless steels, cast iron, harder plastics. |

Practical Tips for Milling Bronze

Beyond choosing the correct end mill, here are a few extra tips to ensure your bronze milling projects go smoothly:

- Use a Cutting Fluid or Lubricant: Even with good chip clearance, machining bronze generates significant heat. A good quality cutting fluid or lubricant will help dissipate heat, reduce friction, and improve the surface finish. It also helps wash away chips.

- Don’t Rush: Bronze can be cut effectively, but it’s not a race. Start with conservative speeds and feeds and increase them gradually as you gain confidence and observe the cut.

- Clean Your Machine Regularly: Bronze chips, being “gummy,” can stick to surfaces. Keep your mill clean to prevent chips from interfering with subsequent operations or getting into other parts of your machine. Visit OSHA’s metal machining safety guidelines to ensure you’re always working safely.

- Consider Depth of Cut: For roughing operations, you might be able to take a more aggressive depth of cut. However, for finishing passes, a lighter depth of cut will yield a much better surface.

- Tool Holder Rigidity: Ensure your end mill is held securely in a rigid tool holder. Any runout or looseness in the holder will exacerbate issues with finish and tool life, especially in a material like bronze.

- Sharp Tools are Essential: A dull end mill will only make bronze harder to machine, leading to more heat and a worse finish. Keep your end mills sharp, or replace them when they start to show signs of wear.

Frequently Asked Questions (FAQ)

Q1: Can I use a 4-flute end mill on bronze at all?

While not ideal for most milling operations, you might be able to use a 4-flute end mill for very light finishing passes if you carefully manage your speeds, feeds, and use plenty of coolant. However, for all significant cutting, including slotting and pocketing, a 3-flute end mill is a much safer and more effective choice.

Q2: What kind of coolant is best for machining bronze?

Water-miscible coolants are generally a good choice for bronze. Look for a synthetic or semi-synthetic coolant designed for non-ferrous metals. They provide good cooling and lubrication. Always follow the manufacturer’s dilution and maintenance instructions.