A 1/8 inch carbide end mill, especially a stub length model with a 1/4 inch shank, is crucial for achieving high Metal Removal Rate (MRR) when cutting acrylic. This specific bit excels due to its geometry and material, offering precision and efficiency for hobbyists and professionals alike.

Working with acrylic on a CNC machine can sometimes feel tricky. You want clean cuts, fast machining, and a tool that just, well, works. That’s where the humble 1/8 inch carbide end mill shines, particularly when you’re looking to push for a high Metal Removal Rate (MRR). It might sound technical, but MRR simply means how quickly you can remove material. For beginners, this is key because it translates to quicker projects and less frustration. Getting started with the right tool makes all the difference. We’ll walk through exactly why this end mill is so good for acrylic and how to use it effectively. Let’s get your CNC projects cutting smoother and faster!

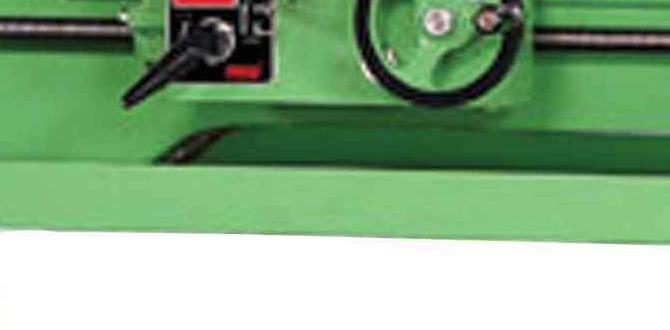

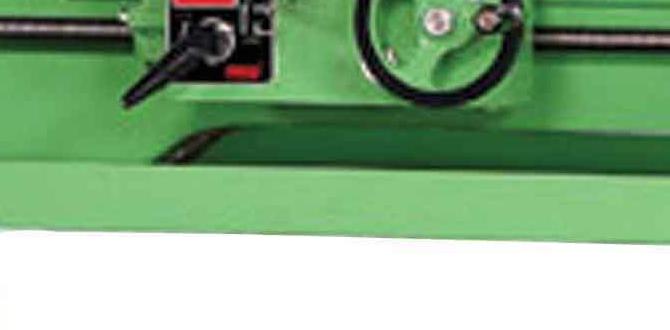

Understanding the 1/8 Inch Carbide End Mill for Acrylic

When you’re diving into CNC machining, especially with a material like acrylic, choosing the right cutting tool is paramount. The 1/8 inch carbide end mill has become a go-to choice for many enthusiasts and professionals, and for good reason. This isn’t just any cutting bit; its specific design and material properties make it exceptionally well-suited for tackling acrylic efficiently and cleanly. Let’s break down what makes this combination work so well.

Why Carbide?

Carbide, or tungsten carbide, is a composite material made from tungsten and carbon atoms. It’s renowned in the machining world for its extreme hardness and wear resistance. When you compare it to High-Speed Steel (HSS), carbide holds an edge much longer and can withstand higher temperatures. This is critical for materials like acrylic, which can melt or gum up if the heat generated during cutting isn’t managed properly. A carbide end mill stays sharp, cuts crisply, and reduces the chances of that dreaded melted plastic mess you can get with softer tools.

The Significance of 1/8 Inch Diameter

The 1/8 inch (or 3.175 mm) diameter is a sweet spot for many smaller CNC machines and detailed work. For acrylic, this size offers a few key advantages:

- Detail and Precision: It allows for fine details and intricate designs that larger bits simply can’t achieve. This is perfect for signs, artistic pieces, or small functional parts.

- Manageable Chip Load: A smaller diameter generally means you can use a lighter chip load. This is the amount of material removed with each rotation of the tool. For acrylic, a controlled chip load helps prevent overheating and chipping.

- Lower Spindle Load: Smaller end mills require less torque from your CNC spindle, making them more forgiving on less powerful machines.

What is “MRR” and Why Does It Matter for Acrylic?

MRR, or Metal Removal Rate, is a metric that quantifies how much material your cutting tool can remove per unit of time. For CNC machining, it’s often calculated as volume removed per minute: cubic inches per minute (in³/min) or cubic millimeters per minute (mm³/min). When we talk about achieving a “high MRR,” we mean cutting material quickly and efficiently.

For acrylic, a high MRR is desirable for several reasons:

- Speed: Faster machining means quicker project completion, which is great for hobbyists balancing time and passion.

- Reduced Heat Buildup: Counterintuitively, cutting faster with the correct parameters can actually reduce heat. When a tool spins too slowly or takes too long to pass through the material, it dwells and transfers more heat. Efficient chip evacuation is key here, and a well-chosen end mill and settings help with that.

- Cleaner Cuts: Proper MRR, along with the right tool and speeds, leads to crisper edges and less chance of melting or chipping.

The Role of “Stub Length” and “1/4 Inch Shank”

When you see “stub length” and “1/4 inch shank” in the context of a 1/8 inch end mill, it refers to specific physical characteristics that enhance its performance:

- Stub Length: This means the flute length (the part of the tool with cutting edges) is shorter than a standard end mill of the same diameter. A shorter flute length provides greater rigidity. For acrylic, this rigidity is crucial. It reduces chatter (vibrations) and deflection, leading to more accurate cuts and a better surface finish. Less deflection means the tool stays on its intended path, crucial for precise details.

- 1/4 Inch Shank: This is the solid, unsharpened portion of the tool that fits into your CNC machine’s collet or tool holder. A 1/4 inch shank is very common for desktop CNC machines and is sturdy enough to handle the forces involved in cutting acrylic with a 1/8 inch cutting diameter. It provides a secure and stable connection.

So, when we talk about a “carbide end mill 1/8 inch 1/4 shank stub length for acrylic high mrr,” we’re referring to a tool specifically designed to cut acrylic quickly and cleanly, offering rigidity and precision ideal for detailed work on common CNC machines.

The Best End Mill for Acrylic: Why This One Wins

You might be wondering, with all the end mill options out there, why is a 1/8 inch carbide end mill, particularly a stub length with a 1/4 inch shank, such a standout for acrylic? It boils down to a combination of material properties, geometrical design, and how those interact with the challenges of cutting acrylic. Let’s dive into the specifics that make this tool a champion for your projects.

Material: The Power of Carbide

First, let’s talk about the material: carbide. Unlike High-Speed Steel (HSS), carbide is incredibly hard and can withstand higher temperatures. Acrylic, when machined, can generate significant heat. If a tool isn’t hard enough or doesn’t manage heat well, it can lead to:

- Melting: The acrylic can liquefy and gum up the flutes of the end mill, leading to poor cut quality and potential tool breakage.

- Dulling: Softer steels will dull quickly, requiring more frequent sharpening or replacement.

- Poor Surface Finish: A dull or overheating tool will leave a rough, hazy, or melted edge on the acrylic.

Carbide’s hardness means it stays sharp longer and can handle the heat associated with faster cutting speeds, which we’ll discuss more later. This translates to cleaner cuts and a longer tool life. For any CNC hobbyist looking for reliability, carbide is the way to go.

Geometry: Designed for Clean Cutting

Beyond the material, the geometry of the end mill itself plays a massive role. For acrylic, specific flute designs are crucial:

- Single Flute vs. Multiple Flutes: For many plastics like acrylic, a single-flute end mill is often preferred. Why? It provides excellent chip evacuation. When cutting plastic, chips can be large and “stringy.” A single flute has more open space in its flutes to clear these chips, preventing recutting and reducing heat buildup. While two-flute bits can also work, single-flute bits are often the go-to for achieving that high MRR and clean finish.

- Polished Flutes: Look for end mills with highly polished flutes. This smooth surface helps the melted plastic slide up and out of the flutes more easily, further preventing gumming and contributing to a cleaner cut and extended tool life.

- Sharp Cutting Edges: The sharpness of the cutting edge is paramount. Carbide allows for very fine, sharp edges that slice cleanly through the acrylic rather than dragging or melting.

The Advantage of Stub Length

The “stub length” specification might seem minor, but it’s significant for rigidity. Standard end mills have a flute length that’s roughly 2 to 4 times their diameter. Stub length end mills have flutes that are shorter, often closer to 1 to 1.5 times the diameter. What does this mean for you?

- Increased Rigidity: A shorter flute length means less “stick-out” and a more robust tool. This reduces the tendency of the end mill to flex or vibrate (chatter) under cutting forces.

- Better Accuracy: When an end mill deflects, your cuts aren’t as accurate as you intended. Stub length bits minimize this deflection, leading to more precise results.

- Higher Feed Rates: Because they are more rigid, stub length end mills can often handle slightly higher feed rates without compromising cut quality, contributing to a higher MRR.

For cutting acrylic, where precise detail and a smooth finish are often desired, this enhanced rigidity is invaluable. It helps prevent chipping and breakout, especially when working near the edges of your material.

The Reliable Workhorse: 1/4 Inch Shank

The 1/4 inch shank is a standard size for many common desktop CNC routers and mills. This means that most hobbyist-grade collets and tool holders will readily accept it. Its solid construction provides a secure grip within your spindle, ensuring that the vibrations and forces of cutting are handled effectively without slippage or runout (wobble). This stability is fundamental for predictable and repeatable machining operations.

Putting It All Together: The Perfect Acrylic Bit

When you combine these features – the hardness of carbide, the efficient chip evacuation of a single-flute design (often found in these), the rigidity of a stub length, and the common, secure 1/4 inch shank – you get an end mill that is specifically optimized for cutting acrylic. It allows you to push for that higher MRR because it can handle the speeds and feeds required, all while maintaining cut quality and tool longevity. This makes the 1/8 inch carbide stub length end mill with a 1/4 inch shank an essential tool for anyone looking to get serious about their acrylic CNC projects.

Mastering High MRR with Your 1/8 Inch Carbide End Mill on Acrylic

Achieving a high Metal Removal Rate (MRR) with your 1/8 inch carbide end mill on acrylic isn’t just about having the right tool; it’s about using it correctly. This involves understanding a few key concepts and dialing in your CNC machine’s settings. Let’s break down how to get the most out of your end mill for speedy, clean acrylic cutting.

Key Parameters for High MRR

The magic happens when you balance three critical settings: Spindle Speed (RPM), Feed Rate, and Depth of Cut (DOC).

1. Spindle Speed (RPM):

- This is how fast the end mill spins. For acrylic with a 1/8 inch carbide end mill, a common starting point is often between 18,000 and 24,000 RPM.

- Why this range? Higher RPMs help the tool cut crisply and can contribute to faster material removal if the feed rate is also appropriate. It also helps the flutes clear chips more efficiently, reducing heat.

2. Feed Rate (IPM or mm/min):

- This is how fast the CNC machine moves the tool through the material. This is arguably the MOST important setting for MRR and cut quality.

- The Goal: You want to feed fast enough to remove material efficiently but not so fast that you overload the end mill, cause excessive heat, or get poor surface finish.

- Starting Points: For a 1/8 inch end mill in acrylic, you might start with feed rates anywhere from 20 to 60 inches per minute (IPM) or 500 to 1500 millimeters per minute (mm/min). This vastly depends on your machine’s rigidity and depth of cut.

- Chip Load Connection: Feed Rate is directly related to Chip Load (F = RPM x N x CL), where N is the number of flutes and CL is the chip load per tooth. A good chip load for acrylic on a 1/8 inch end mill might be around 0.003″ to 0.005″ per tooth.

3. Depth of Cut (DOC):

- This is how deep the end mill cuts into the material in a single pass.

- Rule of Thumb: For a 1/8 inch end mill, especially a stub length, you can often take a fairly aggressive Depth of Cut. A DOC of 0.125″ (1/8 inch) to 0.250″ (1/4 inch) is often achievable for full slotting (cutting a channel all the way through the material).

- Shallow vs. Deep Cuts: While deeper cuts contribute to higher MRR, they also put more stress on the tool and machine. For very thin acrylic, you might need to use shallower DOCs to prevent chipping.

Achieving High MRR Through Strategy

Here’s how to use these parameters strategically:

1. Single Flute End Mills are Your Friend:

- As mentioned, single-flute bits excel at clearing chips from acrylic. This is crucial for preventing heat buildup and gumming, allowing you to maintain higher feed rates.

2. Climb Milling vs. Conventional Milling:

- Climb Milling: The tool rotates in the same direction as the material is being fed. This typically results in a better surface finish and can reduce cutting forces, allowing for higher feed rates. For acrylic, climb milling is often recommended.

- Conventional Milling: The tool rotates against the direction of feed. This can sometimes lead to cutter chatter or a rougher surface on plastics.

- Recommendation: Set your CNC software (CAM) to climb mill whenever possible for acrylic.

3. “High MRR” Specific Techniques:

- Ramping Plunges: Instead of plunging straight down into the material (which generates a lot of heat and stress), use a ramp plunge. The end mill enters the material at an angle (e.g., drill a 5-degree ramp). This allows the bit to cut its way in gradually, improving chip evacuation and reducing heat.

- Optimal Slotting: When cutting a full slot (a channel through the material), you can often use a DOC equal to the diameter of the end mill (0.125″ for your bit) and push your feed rate.

- Adaptive Clearing (if your CAM supports it): This advanced CAM strategy creates tool paths that maintain a consistent chip load by varying the depth and width of cut. It’s highly effective for maximizing MRR while minimizing tool stress and heat.

Example Settings for Acrylic (1/8″ Carbide Single Flute Stub Length)

These are starting points. Always perform test cuts on scrap material and listen to your machine!

For Profiling (Cutting out shapes):

- Spindle Speed: 18,000 RPM

- Feed Rate: 30-40 IPM (approx. 750-1000 mm/min)

- Depth of Cut: 0.125″ (3mm) to 0.250″ (6mm) for full depth cuts if your machine is rigid. For pockets or shallower cuts, 0.125″ is a good starting point.

- Stepover (for pockets): 40-50% of tool diameter (0.050″ – 0.060″)

For Engraving/Detail Work:

- Spindle Speed: 20,000 RPM

- Feed Rate: 20-30 IPM (approx. 500-750 mm/min)

- Depth of Cut: 0.020″ – 0.050″ (0.5mm – 1.2mm) – shallow cuts for surface detail.

Important Considerations for High MRR:**

1. Machine Rigidity: This is paramount. A powerful, rigid CNC machine can handle higher feed rates and depths of cut. A flexy machine will chatter and produce poor results, no matter how good your tool is. Work within your machine’s capabilities.

2. Air Blast or Coolant: While not always used for acrylic, a directed stream of compressed air can help clear chips and cool the cutting zone, extending tool life and improving finishes during high MRR operations.

3. Tool Quality: Invest in a reputable brand. Cheap end mills may have inconsistent carbide, poor coatings, or suboptimal geometry, which will prevent you from achieving those desirable high MRR rates and good finishes.

4. Sound and Vibration: Your ears are your best diagnostic tool. If you hear chattering, screeching, or excessive vibration, slow down your feed rate or reduce your depth of cut. If it sounds like a smooth, efficient cut, you’re likely in the right range.

By understanding these parameters and applying the right strategies, you can leverage your 1/8 inch carbide end mill