Have you ever wondered how a simple piece of metal can turn into a precise tool or part? The magic happens in a workshop where a metal lathe machine works its wonders. One important aspect of this machine is the lathe gear ratio. This ratio helps control the speed of the lathe, making it easier to shape metal accurately.

Imagine trying to make a perfect round shape out of a metal block. Without the right gear ratio, it could be nearly impossible! The lathe gear ratio acts like a superhero, helping the machine achieve the right speed for the job.

Did you know that choosing the right gear ratio can make a huge difference in the final product? A small change can bring out better quality and finish. In this article, we’ll explore how the lathe gear ratio affects a metal lathe machine and why it matters. Prepare to dive into the fascinating world of metalworking!

Understanding Lathe Gear Ratio In Metal Lathe Machines

Understanding Lathe Gear Ratio in Metal Lathe Machines

Lathe gear ratio is essential for metal lathe machines. It determines the speed and torque needed for different tasks. A higher gear ratio means lower speed and more power, great for heavy cuts. Conversely, a lower ratio allows for faster, lighter cuts. This balance helps create precise metal parts. Did you know that adjusting gear ratios can change how a lathe works? It’s like shifting gears in a bicycle! Understanding this concept can improve your machining skills significantly.What is a Lathe Gear Ratio?

Definition of gear ratio in the context of metal lathe machines. Importance of gear ratios for operating efficiency.A gear ratio tells us how fast the lathe spins compared to the motor speed. It’s the magic number for metal lathe machines. Think of it as the machine’s favorite dance move. The right gear ratio boosts operating efficiency and ensures smooth work. If it’s too fast or too slow, the results can be a bit wonky, like trying to do the robot at a slow jam! A good gear ratio makes everything run like a well-oiled machine.

| Gear Ratio | Effect on Speed | Effect on Torque |

|---|---|---|

| High Ratio | Lower Speed | More Torque |

| Low Ratio | Higher Speed | Less Torque |

How Gear Ratios Affect Cutting Performance

Impact of gear ratios on torque and spindle speed. Relationship between gear ratios and surface finish quality.Gear ratios play a key role in how a lathe cuts metal. A higher gear ratio means more torque. This helps the machine exert more strength during cutting. It also affects spindle speed. Higher spindle speed can lead to better surface finishes. On the other hand, low gear ratios can slow down cutting but allow for more control, especially on tough materials. Knowing how to balance these factors can improve your metalworking results.

How do gear ratios impact torque and spindle speed?

Higher gear ratios give more torque but reduce spindle speed. Lower gear ratios offer faster speeds with lower torque.

Key Effects of Gear Ratios

- High gear ratios = strong cutting force

- Low gear ratios = faster cutting speed

- Surface finish improves with right gear ratio adjustments

Calculating Gear Ratios for Metal Lathes

Stepbystep guide on how to compute gear ratios. Examples of gear ratio calculations for different lathe setups.Calculating gear ratios for your metal lathe machine is simple. First, divide the number of teeth on the driven gear by the teeth on the driving gear. Here’s how you can do it in a few easy steps:

- Count teeth on the driving gear.

- Count teeth on the driven gear.

- Use this formula: Gear Ratio = Driven Teeth ÷ Driving Teeth.

For example, if the driving gear has 10 teeth and the driven gear has 40 teeth, the gear ratio equals 40 ÷ 10 = 4. This means the lathe spins four times slower than the driving gear. You can try this with different setups to see how the speed changes!

Why are gear ratios important?

Gear ratios determine how fast your lathe spins. They help in choosing the right speed for different types of work.

Choosing the Right Gear Ratio for Your Project

Factors to consider when selecting gear ratios for specific machining tasks. Recommendations for optimal gear ratios based on material types.Gear ratios play a key role in machining tasks. They determine how fast and efficiently your lathe works. To choose the right gear ratio, consider these factors:

- Material type: Softer materials need lower ratios, while hard metals require higher ratios.

- Desired finish: A smoother finish may need a slower speed.

- Tool wear: Higher speeds can wear out tools faster.

For optimal results, here are some recommendations:

- Aluminum: Use a ratio of 3:1.

- Steel: A 5:1 ratio works best.

- Cast iron: Go for a 7:1 ratio.

What gear ratio should I use for different materials?

Use lower ratios for soft materials and higher ratios for hard metals. This helps in achieving better results and minimizing tool wear.

Common Mistakes in Gear Ratio Usage

Identification of frequent errors made by users regarding gear ratios. Tips for avoiding these mistakes to enhance machining results.Many users trip over common mistakes when using gear ratios. One common error is not adjusting the ratio for different materials. This could make your lathe work as smoothly as a cat in a bathtub! Another issue is forgetting to double-check the settings. Always read the manual; it’s there for a reason! To improve your machining results, consider this copper penny: even the tiniest adjustments can make a big difference.

| Error | Tip to Avoid |

|---|---|

| Using incorrect ratio | Check material type! |

| Neglecting to read settings | Always consult the manual! |

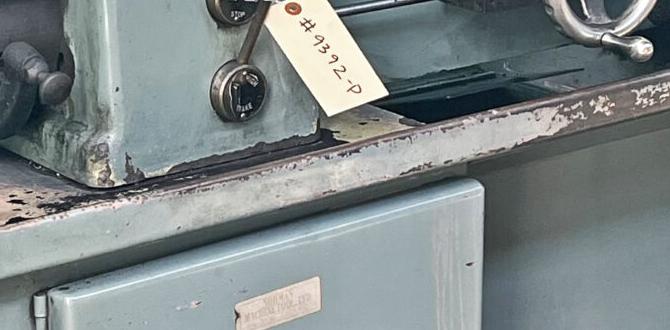

Upgrading Your Metal Lathe: Gear Ratio Considerations

Factors to evaluate when modifying or upgrading existing gear ratio setups. Benefits of modernizing gear ratios to improve productivity and precision.Upgrading your metal lathe with a new gear ratio can make a big difference. First, consider your current tasks. Are you cutting thick metal or making fine details? Next, think about productivity. A better gear ratio helps you work faster. Lastly, precision is key. The right setup can improve your accuracy. Here are some things to keep in mind:

- Type of projects you do

- Desired speed and torque

- Compatibility with existing parts

Modernizing gear ratios can boost your skills and save time. A happy lathe means happy makers!

Why should I upgrade my lathe gear ratio?

Upgrading the gear ratio improves efficiency and accuracy. It allows your lathe to handle different jobs better. This change makes every project easier and faster.

Maintenance Tips for Lathe Gears

Best practices for maintaining gear systems to ensure longevity. Troubleshooting common gearrelated issues in metal lathe machines.Keeping your lathe gears happy is key to making them last. First, make sure to oil them often. This helps them move smoothly. Avoid running them dry, as that can create squeaks that sound like a cat in a blender! Regularly check for dirt and debris. A quick clean can prevent big issues later. If a gear starts to slip, it might need replacing or tightening. Don’t be shy about checking for signs of wear. Keeping gears in shape saves time and money!

| Maintenance Task | How Often? |

|---|---|

| Oiling | Every 10 hours of use |

| Cleaning | Weekly |

| Inspection | Monthly |

Conclusion

In conclusion, understanding lathe gear ratios is key to using a metal lathe machine effectively. The gear ratio affects speed and torque, making it crucial for your projects. You can explore different ratios to find what works best for you. We encourage you to practice and read more about lathe settings to improve your metalworking skills. Happy turning!FAQs

Sure! Here Are Five Questions Related To The Topic Of Lathe Gear Ratio In Metal Lathe Machines:Sure! Here are five questions about lathe gear ratio: 1. **What is a lathe?** A lathe is a machine that cuts and shapes materials like metal. 2. **What does gear ratio mean?** Gear ratio shows how many times one gear turns for each turn of another gear. 3. **Why is gear ratio important?** It helps control the speed and power of the lathe while you work. 4. **How do you change the gear ratio?** You can change it by swapping gears or adjusting settings on the lathe. 5. **What happens if the gear ratio is too high?** If it’s too high, the lathe might go too fast, making it hard to control.

Sure! Just let me know what question you want me to answer, and I’ll keep it simple.

What Is The Significance Of Gear Ratio In A Metal Lathe Machine And How Does It Affect Cutting Speeds?The gear ratio in a metal lathe machine helps you control how fast the tool spins. If the gear ratio is higher, the tool spins faster. This means you can cut through metal more quickly. If it’s lower, the tool goes slower, which can be better for detailed work. So, the gear ratio is important for speed and type of cutting we want to do.

How Can The Gear Ratio Be Adjusted On A Metal Lathe To Accommodate Different Materials And Cutting Requirements?You can adjust the gear ratio on a metal lathe by changing the gears or using levers. This lets you control how fast the metal moves. Different materials, like soft or hard metal, need different speeds. For soft materials, use a higher speed, and for hard ones, go slower. This adjustment helps you cut better and makes the work easier.

What Calculations Are Necessary To Determine The Optimal Gear Ratio For Specific Machining Operations On A Lathe?To find the best gear ratio for a lathe, you need to know a few things. First, you look at the speed of the lathe and the tool you want to use. Then, you find out how fast you need the tool to spin for the job. You can do this by dividing the lathe speed by the tool speed. This gives you the gear ratio, which helps the lathe work better for your task.

How Do Different Gear Ratios Influence The Torque And Power Output Of A Metal Lathe During Operation?Different gear ratios change how fast the lathe’s spindle turns. A lower gear ratio gives you more torque, which helps turn tough metal. This means you can cut better but might go slower. A higher gear ratio makes the spindle turn faster, giving you less torque. This is good for light work but not for hard materials.

What Are The Common Gear Ratios Available In Metal Lathe Machines, And How Do They Impact The Precision And Finish Of Machined Parts?Metal lathe machines usually have gear ratios like 1:1, 2:1, and 4:1. A gear ratio tells us how many times the spindle turns for each turn of the handle. Higher gear ratios can make the lathe go faster but may lower the finish quality. Lower gear ratios offer more precision for detailed work. So, you can choose the ratio that fits your project best!