Imagine creating something amazing with just a machine. Have you ever heard of a metal lathe? This tool shapes metal into all kinds of useful items. From parts in cars to tools for your workshop, a lathe is a magic machine for metal shaping.

Setting up a metal lathe might seem tricky at first. But once you know the basics, it can be a fun challenge. You can craft items that fit your needs perfectly. Did you know that many famous inventors started with just a lathe? It’s true! This simple tool has shaped history.

In this article, we will walk you through the steps of setting up your lathe. You’ll discover tips and tricks that will make your metal shaping journey easier. Are you ready to dive into the world of metal lathes? Let’s get started!

Lathe Metal Shaping: Mastering Your Metal Lathe Setup

Lathe Metal Shaping: Metal Lathe Setup

Setting up a metal lathe can be fun and challenging. Did you know that a properly arranged lathe can make shaping metal easier and smoother? First, ensure your workspace is clean and safe. Next, carefully mount your metal piece on the lathe’s chuck. Adjust the speed based on the material you use. Proper tool positioning is key, too! With the right setup, you can create amazing shapes and parts. Dive in and discover the exciting world of metalworking!

Understanding Metal Lathes

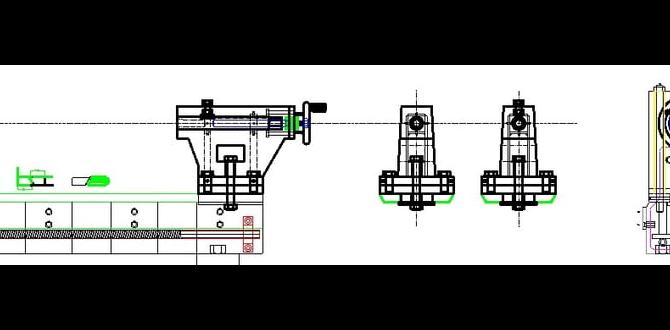

Definition and purpose of a metal lathe. Key components and their functions.

A metal lathe is a machine that shapes metal. It spins the metal while tools cut or shape it. This helps make parts for machines and vehicles. It’s an important tool in workshops.

Key parts of a metal lathe include:

- Headstock: It holds the motor and spins the workpiece.

- Tailstock: It supports the other end of the workpiece.

- Carriage: It moves the cutting tool along the metal.

- Bed: This is the base that keeps everything stable.

Each part has a special job. Together, they help create many objects we use every day.

What is the importance of a metal lathe?

A metal lathe is essential for precise metal shaping. It allows for accurate dimensions and smooth finishes. It is widely used in manufacturing and repairs.

Essential Tools and Accessories for Lathe Setup

List of musthave tools for optimal lathe performance. Importance of quality accessories in metal shaping.

Setting up a lathe for metal shaping? You’ll need some essential tools and accessories to make it shine. Think of quality tools as the secret sauce that makes everything work better. A good chuck holds your work piece tightly, while sharp tools make smooth cuts. Don’t forget the tailstock for stability! Check out our list below for must-have items:

| Tool/Accessory | Purpose |

|---|---|

| Chuck | Holds the work piece tight as a drum. |

| Cutting Tools | Shapes metal like a pro chef slices vegetables. |

| Tailstock | Adds support for longer pieces – no wobbling! |

| Caliper | Ensures precision, making sure your piece doesn’t come out like a banana. |

With these tools, your lathe will perform like a rock star. Quality accessories can make all the difference in metal shaping. They enhance accuracy and smoothness. So, gear up and get ready to shape metal like a wizard!

Preparing for Lathe Setup

Necessary workspace considerations and safety precautions. Guidelines for selecting the right metal for shaping.

Before setting up your lathe, ensure you have the right workspace. Keep the area clean and free of clutter. Safety gear is essential. Always wear safety glasses and ear protection. Consider the type of metal you will shape. Select materials like aluminum or brass for easy handling.

- Workspace: Choose a bright, spacious area.

- Safety Precautions: Use gloves and an apron.

- Metal Selection: Soft metals are best for beginners.

What are the best materials for lathe work?

Use aluminum, brass, or plastic for easier shaping. These materials are gentle on your tools and help you learn the skills needed for more challenging metals later.

Step-by-Step Lathe Setup Process

Detailed instructions for assembling and calibrating the lathe. Tips for ensuring precision alignment and leveling.

Setting up a lathe can seem tricky, but it’s easy with clear steps. Start by assembling the main parts like the bed and tailstock. Use a level to check it is flat. Calibrate the center height for precision. Here are some tips:

- Check for straightness using a ruler.

- Securely tighten all bolts.

- Use a dial indicator to align tools.

Follow these steps carefully to ensure your lathe works well.

How do you properly set up a lathe?

To properly set up a lathe, follow the steps above. Also, ensure that all parts are tight and in place. A well-set lathe helps you create precise work pieces.

Common Problems and Troubleshooting

Identification of frequent issues during lathe operation. Solutions for improving performance and preventing errors.

Working with a lathe can feel like a fun game, but sometimes it turns into a puzzle! Common problems include vibration, uneven cuts, and strange noises. These can happen if tools are dull or settings are off. The good news? Most of these issues have simple fixes. Check your tools regularly and maintain proper speeds and feeds. Remember, a happy lathe makes happy parts!

| Problem | Possible Cause | Solution |

|---|---|---|

| Vibration | Loose components | Tighten all screws |

| Uneven cuts | Dull cutting tool | Sharpen the tool |

| Strange noises | Poor lubrication | Lubricate moving parts |

Maintaining Your Metal Lathe

Routine maintenance tasks for longevity and reliability. Tips for troubleshooting and repairs.

To keep your metal lathe happy, routine maintenance is key. Regularly check for loose parts and clean off dust like you’re tidying up your room. If something breaks, don’t panic! Troubleshooting can be as easy as checking the power supply first. Remember, even lathes enjoy a little pampering—so grease those moving parts! A happy lathe means better accuracy and less fuss. You want it spinning smoothly, not like a roller coaster!

| Maintenance Task | Frequency |

|---|---|

| Clean and lubricate | Weekly |

| Tighten bolts and screws | Monthly |

| Inspect belts and gears | Quarterly |

| Check power connections | As needed |

Resources for Further Learning

Recommended books, websites, and forums for enthusiasts. Information on workshops and handson training opportunities.

There are many great resources for learning about metal shaping and lathe setups. Here are some suggestions:

- Books: Look for titles about metalworking, like “The Metal Lathe” by Tom Lipton.

- Websites: Check out sites like The Home Machinist and Machinist’s Workshop for helpful tips.

- Forums: Join online communities to ask questions and share experiences.

- Workshops: Search for local workshops to get hands-on training.

These resources can enhance your skills and make learning fun!

What are good resources for learning about metal lathe setup?

Books, websites, and forums are great resources for learning about metal lathe setups. Look for local workshops for hands-on experience. Participate in forums to connect with other metalworking enthusiasts!

Conclusion

In summary, setting up a metal lathe is important for shaping metal accurately. First, choose the right tools. Next, ensure proper measurements. Safety is key, so always wear protective gear. Experiment with different materials to improve your skills. If you’re eager to learn more, check out online tutorials or visit a local workshop for hands-on experience!

FAQs

What Are The Essential Components Of A Metal Lathe And How Do They Contribute To The Shaping Process?

A metal lathe has a few important parts. First, it has a bed that holds everything steady. Then, there’s the headstock, which spins the metal piece. The tailstock helps hold the other end of the metal. Lastly, there’s the cutting tool, which shapes the metal as it spins. Together, these parts help you create different shapes in metal.

How Do You Properly Set Up A Metal Lathe For Machining Different Materials Such As Aluminum, Steel, And Brass?

To set up a metal lathe, first, choose the right cutting tool for your material. For aluminum, use a sharp tool that cuts easily. For steel, use a tougher tool that can handle the hardness. For brass, a tool with a nice edge works best. Then, adjust the speed of the lathe for each metal: faster for aluminum, slower for steel, and medium for brass. Lastly, make sure everything is tight and safe before you start.

What Safety Precautions Should Be Considered When Operating A Metal Lathe?

When using a metal lathe, wear safety goggles to protect your eyes. Keep long hair tied back and wear tight clothing to avoid getting caught in the machine. Always use tools, not your hands, to move items. Make sure the area is clean and free from clutter. Finally, never touch the moving parts while the machine is on.

How Can Different Cutting Tools And Insert Types Affect The Performance And Finish Of Workpieces On A Metal Lathe?

Different cutting tools and insert types change how well a metal lathe works. Some tools cut faster and leave smoother surfaces on the metal. Others might wear out quickly, which can affect the quality of what you make. If you pick the right tool, you can make your projects look nicer and finish them quicker. It’s all about choosing what works best for your job!

What Are The Common Troubleshooting Steps To Take When A Metal Lathe Is Producing Inaccurate Or Poor-Quality Cuts?

If your metal lathe isn’t cutting well, first check the tool. Make sure it is sharp and clean. Next, look at the workpiece. Ensure it is securely clamped in place. You should also check the speed settings. Adjust them if they seem too high or too low. Lastly, see if the lathe is level. A level lathe helps make better cuts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components Of A Metal Lathe And How Do They Contribute To The Shaping Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe has a few important parts. First, it has a bed that holds everything steady. Then, there’s the headstock, which spins the metal piece. The tailstock helps hold the other end of the metal. Lastly, there’s the cutting tool, which shapes the metal as it spins. Together, these parts help you create different shapes in metal.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Metal Lathe For Machining Different Materials Such As Aluminum, Steel, And Brass? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe, first, choose the right cutting tool for your material. For aluminum, use a sharp tool that cuts easily. For steel, use a tougher tool that can handle the hardness. For brass, a tool with a nice edge works best. Then, adjust the speed of the lathe for each metal: faster for aluminum, slower for steel, and medium for brass. Lastly, make sure everything is tight and safe before you start.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Considered When Operating A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, wear safety goggles to protect your eyes. Keep long hair tied back and wear tight clothing to avoid getting caught in the machine. Always use tools, not your hands, to move items. Make sure the area is clean and free from clutter. Finally, never touch the moving parts while the machine is on.”}},{“@type”: “Question”,”name”: “How Can Different Cutting Tools And Insert Types Affect The Performance And Finish Of Workpieces On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tools and insert types change how well a metal lathe works. Some tools cut faster and leave smoother surfaces on the metal. Others might wear out quickly, which can affect the quality of what you make. If you pick the right tool, you can make your projects look nicer and finish them quicker. It’s all about choosing what works best for your job!”}},{“@type”: “Question”,”name”: “What Are The Common Troubleshooting Steps To Take When A Metal Lathe Is Producing Inaccurate Or Poor-Quality Cuts? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe isn’t cutting well, first check the tool. Make sure it is sharp and clean. Next, look at the workpiece. Ensure it is securely clamped in place. You should also check the speed settings. Adjust them if they seem too high or too low. Lastly, see if the lathe is level. A level lathe helps make better cuts.”}}]}