Have you ever wondered how metal parts are shaped with incredible precision? One of the most fascinating tools for this task is the metal lathe. This machine is not just any tool; it’s a metal shaping wizard! With a metal lathe, you can create, cut, and shape metal into nearly any design you can imagine.

Imagine your favorite toy car. Did you know that machines like the metal lathe might have helped make its parts? These lathes can perform many tasks, but one of the coolest functions is thread cutting. Thread cutting is how we create those spirals that let screws hold things together. It’s amazing how metal lathes shape our everyday lives!

Whether you’re a budding engineer or someone who enjoys crafts, understanding metal lathes opens a world of creativity. Have you ever thought about building something out of metal? With the right guidance, anyone can learn to use a lathe and create stunning pieces. So, let’s dive into the exciting world of lathe metal shaping and explore how these machines work!

Lathe Metal Shaping: Mastering Metal Lathe Thread Cutting Techniques

Lathe Metal Shaping: Mastering Thread Cutting

Lathe machines are essential tools for shaping metal. They can create precise parts through processes like thread cutting. Using a metal lathe, you can turn raw materials into finely threaded components for all kinds of projects. Imagine building your own toys or gadgets! Did you know that mastering lathe techniques can also lead to amazing creations, like custom bike parts? Learn the basics of metal shaping and unlock your inventiveness with a simple lathe.

Understanding the Basics of Metal Lathes

Definition and functions of a metal lathe. Key components and their roles in metal shaping.

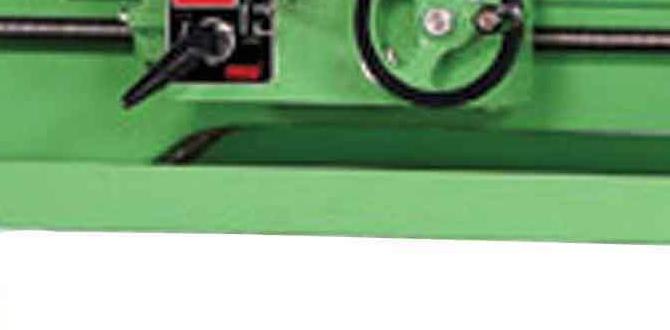

A metal lathe is like a magic wand for shaping metal! It spins metal while sharp tools cut and carve it into specific shapes. Think of it as a giant pencil sharpener, but instead of wood, it works with metals. The main parts include the bed, which holds everything in place; the headstock, where the spinning happens; and the tailstock, which helps support long pieces. These components work together to transform raw metal into beautiful shapes, like tiny metal sculptures or practical tools.

| Component | Function |

|---|---|

| Bed | Supports and aligns components |

| Headstock | Holds the motor and spins the workpiece |

| Tailstock | Supports the other end of the workpiece |

Incredibly, these machines can produce threads, grooves, and even custom shapes. It’s like doing magic tricks with metal! So, grab your wizard hat, and let’s shape some metal together!

The Process of Thread Cutting on a Lathe

Stepbystep guide on setting up for thread cutting. Common techniques and methodologies for thread cutting.

Thread cutting on a lathe is simple if you follow the right steps. First, secure your material. Then, set the tool to the right position. Adjust the speed to match your needs. Here are some common techniques:

- Use of a threading tool for accuracy

- Applying the correct depth of cut

- Maintaining even pressure while cutting

These steps help to achieve smooth, precise threads.

What steps are involved in thread cutting?

Start by securing the workpiece, setting the right tool position, and adjusting the speed. This ensures a clean cut and better results.

Tools and Accessories for Lathe Operations

Essential tools for successful thread cutting. Recommended accessories to enhance lathe performance.

Using the right tools makes thread cutting a breeze! You’ll need essentials like cutting tools, thread gauges, and a tailstock. These buddies help you make smoother cuts and perfect threads. Recommended accessories include a steady rest, which prevents your workpiece from wiggling like jelly. How about tool holders? They keep your tools safe and ready for action. Add a handy oil mister for better performance, leaving your lathe feeling as slick as a seal at the beach!

| Essential Tools | Recommended Accessories |

|---|---|

| Cutting Tools | Steady Rest |

| Thread Gauges | Tool Holders |

| Tailstock | Oil Mister |

Common Challenges in Metal Shaping and Thread Cutting

Identification of common issues faced during lathe operations. Solutions and tips to overcome these challenges.

Working with a lathe can feel like a dance, but sometimes you step on your own toes! Common issues include vibrations, poor finish, and incorrect threading. These can lead to frustration and wasted materials. Luckily, there are solutions! Check tool setups, use proper speeds, and regularly maintain your equipment. Remember, it’s okay to take a break; a fresh mind can turn errors into masterpieces.

| Challenge | Solution |

|---|---|

| Vibrations | Check for loose parts |

| Poor finish | Adjust speed and feed |

| Incorrect threading | Verify tool alignment |

Safety Precautions When Using a Metal Lathe

Importance of safety measures and gear. Best practices to maintain a safe working environment.

Using a metal lathe can be fun but also dangerous. It’s very important to follow safety measures. This keeps you safe while working. Always wear safety gear, like goggles and gloves. Keep the workspace clean and organized. A tidy area helps prevent accidents. Remember these tips:

- Always wear protective eyewear and gloves.

- Keep tools and materials away from spinning parts.

- Check your machine before starting it.

- Don’t wear loose clothing or jewelry.

Staying safe makes your work enjoyable. It’s better to be safe than sorry!

Why is safety gear important?

Using safety gear protects you from flying debris and sharp edges. Always wear safety goggles to shield your eyes and gloves for hand protection.

Advanced Techniques in Metal Shaping

Exploring CNC lathes and automation in metal shaping. Innovations in lathe technology for precision and efficiency.

CNC lathes are changing the way we shape metal. These machines use computers to guide their movements. This makes them very precise. Automation helps factories run smoothly and faster. It reduces the chances of errors.

New lathe technology improves efficiency. This means we can create high-quality parts quickly. Here are some key benefits:

- Precision: Machines make exact cuts every time.

- Speed: Work gets done in less time.

- Less waste: More metal is turned into usable parts.

- Safety: Fewer injuries with automated systems.

Innovation is key in metal shaping. As machines get better, our products can be better too!

What are the benefits of CNC lathes in metal shaping?

CNC lathes offer precision, speed, safety, and less waste in metal shaping.

Maintenance Tips for Longevity of Metal Lathes

Routine maintenance practices to extend the life of a lathe. Signs that indicate maintenance is needed.

Keeping a metal lathe in good shape is simple. Regular checks can help a lot. Clean the lathe after each use. Oil the moving parts to avoid rust. Check the belts and adjust them if needed. Also, look for worn tools. Signs that your lathe needs help include unusual noise, vibrations, or sticking parts.

- Clean regularly

- Oil moving parts

- Check belts

- Inspect tools

What is routine maintenance for a lathe?

Routine maintenance includes cleaning, lubricating parts, and checking tools. This helps the lathe last longer and work better.

Taking care of your lathe is worth it. It can save money on repairs and make your projects easier. Regular maintenance extends the life of your lathe and keeps it running smoothly.

Choosing the Right Lathe for Your Needs

Factors to consider when selecting a metal lathe. Comparison of popular metal lathes in the market.

Finding the perfect metal lathe is like dating—there’s a lot to consider! First, think about your budget. Lathes come in all prices, so know what you can spend. Next, think about your project needs. Will you be shaping metal or cutting threads? Each lathe has its strengths. Popular choices include the Grizzly G0602 and the Jet JWL-1442. Both are excellent, but they have different features. Check the table below for a quick comparison!

| Model | Price | Best for |

|---|---|---|

| Grizzly G0602 | $$$ | Beginners |

| Jet JWL-1442 | $$$$ | Advanced users |

Conclusion

In conclusion, metal lathes shape and cut metal effectively. They help you create precise threads for fittings. Learning to use a lathe can boost your skills in metalworking. We encourage you to explore tutorials and practice safe techniques. By mastering these skills, you can create amazing projects and improve your craftsmanship. Start experimenting and enjoy the process!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Thread Cutting:

Sure! A lathe is a machine that helps shape metal. It spins the metal while we use tools to carve it into different shapes. We can also cut threads, which are spirals that help two pieces fit together tightly. This is important for making things like bolts and screws. It’s like carving a shape out of dough, but with metal!

Sure! Please give me the question you’d like me to answer.

What Are The Key Differences Between A Metal Lathe And Other Types Of Lathes, Such As Wood Lathes, In Terms Of Functionality And Applications?

A metal lathe and a wood lathe are tools we use for shaping materials. A metal lathe is strong and cuts metal, while a wood lathe shapes wood. Metal lathes can make precise parts for machines, but wood lathes create bowls or furniture. The tools and techniques are different because the materials are different. So, we choose the lathe based on what we want to make!

How Do You Set Up A Metal Lathe For Precision Thread Cutting, And What Tools Are Essential For Achieving Accurate Threads?

To set up a metal lathe for cutting precise threads, you first need to adjust the settings. Check the speed and make sure the tool is sharp. You also need to set the right pitch, which controls how tight the threads are. Essential tools include a measuring tool to check your work and a threading tool to cut the threads. Always wear safety gear to protect yourself while you work!

What Are The Common Types Of Threads That Can Be Cut Using A Metal Lathe, And How Do Their Specifications Differ?

You can cut different types of threads using a metal lathe. The most common types are standard (or inch) threads and metric threads. Standard threads use inches for size, while metric threads use millimeters. They also have different shapes, like sharp or rounded edges. These differences help them fit better in different machines or tools.

What Safety Precautions Should Be Taken When Operating A Metal Lathe During The Metal Shaping And Thread Cutting Processes?

When using a metal lathe, we should always wear safety goggles to protect our eyes. You should tie back long hair and avoid loose clothing that could get caught in the machine. Keep your hands clear of the moving parts, and use tools to help instead of your fingers. Always keep the area clean so you don’t trip or bump into things. Lastly, make sure to follow the machine’s rules and ask for help if you’re unsure.

How Can Cad (Computer-Aided Design) Software Be Used To Improve The Efficiency And Accuracy Of Metal Shaping And Thread Cutting On A Lathe?

You can use Computer-Aided Design (CAD) software to plan your metal shapes and threads before starting. This helps you see mistakes on a computer screen instead of on the real metal. You can set specific measurements, making shapes and threads accurate. Also, CAD lets you create designs quickly, saving time and reducing waste. This way, your work becomes easier and better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Thread Cutting:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps shape metal. It spins the metal while we use tools to carve it into different shapes. We can also cut threads, which are spirals that help two pieces fit together tightly. This is important for making things like bolts and screws. It’s like carving a shape out of dough, but with metal!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between A Metal Lathe And Other Types Of Lathes, Such As Wood Lathes, In Terms Of Functionality And Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe and a wood lathe are tools we use for shaping materials. A metal lathe is strong and cuts metal, while a wood lathe shapes wood. Metal lathes can make precise parts for machines, but wood lathes create bowls or furniture. The tools and techniques are different because the materials are different. So, we choose the lathe based on what we want to make!”}},{“@type”: “Question”,”name”: “How Do You Set Up A Metal Lathe For Precision Thread Cutting, And What Tools Are Essential For Achieving Accurate Threads?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe for cutting precise threads, you first need to adjust the settings. Check the speed and make sure the tool is sharp. You also need to set the right pitch, which controls how tight the threads are. Essential tools include a measuring tool to check your work and a threading tool to cut the threads. Always wear safety gear to protect yourself while you work!”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Threads That Can Be Cut Using A Metal Lathe, And How Do Their Specifications Differ?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can cut different types of threads using a metal lathe. The most common types are standard (or inch) threads and metric threads. Standard threads use inches for size, while metric threads use millimeters. They also have different shapes, like sharp or rounded edges. These differences help them fit better in different machines or tools.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe During The Metal Shaping And Thread Cutting Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, we should always wear safety goggles to protect our eyes. You should tie back long hair and avoid loose clothing that could get caught in the machine. Keep your hands clear of the moving parts, and use tools to help instead of your fingers. Always keep the area clean so you don’t trip or bump into things. Lastly, make sure to follow the machine’s rules and ask for help if you’re unsure.”}},{“@type”: “Question”,”name”: “How Can Cad (Computer-Aided Design) Software Be Used To Improve The Efficiency And Accuracy Of Metal Shaping And Thread Cutting On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use Computer-Aided Design (CAD) software to plan your metal shapes and threads before starting. This helps you see mistakes on a computer screen instead of on the real metal. You can set specific measurements, making shapes and threads accurate. Also, CAD lets you create designs quickly, saving time and reducing waste. This way, your work becomes easier and better!”}}]}