Quick Summary

Confused about wood lathes versus metal lathes? A wood lathe shapes softer materials with speed and artistry, while a metal lathe handles tougher metals with precision and power. Understanding their core differences in construction, speed, tooling, and application is key to choosing the right machine for your workshop dreams. This guide breaks it down simply.

Choosing the right lathe can feel a bit overwhelming when you first dive into machining or woodworking. You see these amazing creations, and you know a lathe was involved, but the terminology can get blurry. What’s the real scoop on a wood lathe versus a metal lathe? Are they just different sizes, or is there more to it? Getting this right from the start saves you time, money, and a whole lot of frustration. We’ll clear up the confusion, show you the essential distinctions, and help you figure out which kind of lathe might be your next best friend in the workshop.

Wood Lathe vs. Metal Lathe: The Big Picture

At a glance, both wood lathes and metal lathes are machines designed to spin a workpiece. You then use cutting tools to shape that spinning material. Think of it like a potter’s wheel for wood or metal. However, the materials they’re built to handle—wood versus metal—dictate significant differences in their design, construction, and operation. This fundamental distinction is what we’ll explore.

Core Differences Explained

The main differences between a wood lathe and a metal lathe stem from the properties of the materials they process. Wood is relatively soft, forgiving, and can be worked at higher speeds. Metal is much harder, requiring more force, slower speeds, and much sturdier machinery to manage the stresses and heat generated during cutting.

1. Construction and Robustness

This is perhaps the most obvious difference. Metal lathes are built like tanks. They need to withstand the incredible forces generated when cutting steel, aluminum, or brass. The bed, headstock, tailstock, and tool rest (on a wood lathe) or carriage (on a metal lathe) are all made from heavy-duty cast iron or steel. This mass is crucial for absorbing vibrations and maintaining accuracy, especially when taking heavier cuts.

Wood lathes, on the other hand, don’t need to be quite as massive. While many higher-end wood lathes are also made of cast iron for stability, lighter-duty models might have steel tubing beds or lighter frames. They are designed to handle the lighter forces of shaping wood, which is considerably less dense and requires less brute strength to remove material.

2. Speed and Power

Wood lathes typically operate at much higher spindle speeds than metal lathes. Speeds can range from a few hundred RPM (Revolutions Per Minute) for larger pieces or rough turning, all the way up to 3,000-4,000 RPM or even higher for smaller, detailed work. Higher speeds are great for achieving a smooth finish on wood with sharp chisels or scraping tools.

Metal lathes operate at significantly lower speeds. Depending on the material being cut and the tool used, speeds might range from as low as 30 RPM for heavy steel cutting to 1,500-2,000 RPM for lighter work or finishing passes. This is because metal cutting generates a lot of heat and requires more force, and faster speeds would make the tool and workpiece overheat or chatter uncontrollably. Metal lathes also require more powerful motors to overcome the resistance of the metal.

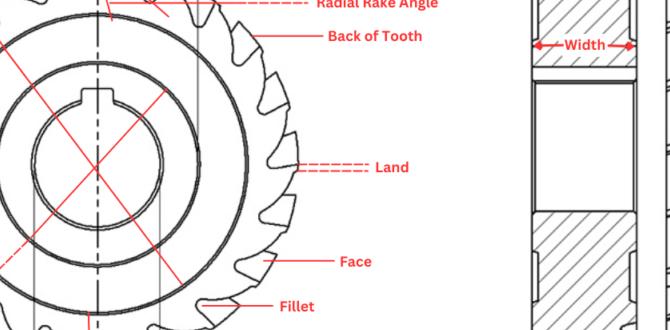

3. Tooling and Cutting Methods

The tools used on each type of lathe are fundamentally different, tailored to the material and speed.

- Wood Lathe Tools: Typically involve chisels, gouges, and scrapers. These are often held by hand or supported by a tool rest. The user applies leverage and skill to shape the wood. The cutting action relies on sharp edges slicing through the wood fibers.

- Metal Lathe Tools: Use rigid “cutting bits” or “tool bits” made of high-speed steel (HSS), carbide, or other hard alloys. These bits are held securely in a tool post on the carriage, which moves along the lathe bed. They are designed to shear off small chips of metal. This requires precise control over depth of cut and feed rate.

4. Precision and Accuracy

Metal lathes are designed for a much higher degree of precision. They have features like graduated dials on the carriage and tailstock, allowing for very fine adjustments, often measured in thousandths of an inch or hundredths of a millimeter. This is essential for creating precisely fitting parts, threads, or complex mechanical components.

While a good wood lathe can be accurate, the inherent nature of hand tools and wood grain means absolute precision to thousandths of an inch is rarely the goal or achievable in the same way. Woodworking often tolerates slightly wider tolerances, focusing more on form and finish.

5. Safety Considerations

Both machines require strict safety protocols, but the nature of the hazards differs.

- Wood Lathe Safety: Primary concerns include flying chips (requiring eye protection and sometimes a face shield), catching loose clothing or long hair, and ensuring the workpiece is securely mounted. The high RPMs mean that if something goes wrong, like a poorly secured piece, it can be ejected with considerable force.

- Metal Lathe Safety: Involves sharp metal chips (requiring eye protection and sometimes chip guards), the risk of entanglement with rotating parts, handling heavy materials and tooling, and managing heat and potential coolant splashes. Metal shavings are sharp and can cause serious cuts.

Always refer to the Occupational Safety and Health Administration (OSHA) guidelines for safe operation of any machinery.

Key Components: How They Differ

Let’s look at some specific parts of these machines and how their design reflects their intended use.

The Bed

The bed is the backbone of the lathe. On a metal lathe, it’s usually a very thick, precisely machined casting of gray iron, often with V-shaped ways (grooves) that guide the carriage and tailstock. This ensures they stay aligned during operation.

Wood lathes may have similar cast iron beds, but lighter-duty models might use steel tubes or rails. The precision required for the ways is generally less critical than on a metal lathe, as the tool is often hand-held or guided differently.

Headstock and Spindle

The headstock houses the motor and drive mechanism, and the spindle is the part that rotates and holds the workpiece. Metal lathe spindles are typically more robust, often featuring a Morse taper (a standardized angled connection) for securely holding chucks and driving centers. They are designed to handle significant torque.

Wood lathe headstocks also hold the motor, but the spindle design prioritizes different needs. They often have a screw thread on the end for mounting faceplates and chucks. While strong, they don’t typically need to transmit the same extreme torque as a metal lathe spindle.

Tailstock

The tailstock on both lathes provides support for the workpiece (via a center) or holds tools like drill bits or reamers. On a metal lathe, the tailstock is crucial for supporting longer workpieces and must align perfectly with the headstock spindle. It often has a quill that extends and retracts with precise control.

Wood lathe tailstocks serve a similar purpose but may be less precisely aligned and less critically used for heavy support, as wood isn’t as prone to bending or deflection under its own weight between supports as metal can be. However, a stable tailstock is still vital for safe operation when turning longer pieces.

Tool Rest vs. Carriage

This is a defining difference in how users interact with the workpiece.

- Wood Lathe: Features a simple, adjustable tool rest. The woodturner moves their chisels and gouges against this rest, using it as a pivot point. The tool rest is positioned close to the workpiece, and the operator controls the cutting action with their hands.

- Metal Lathe: Uses a complex carriage assembly. This includes the cross-slide and compound rest, which hold the metal cutting tool rigidly. The carriage moves along the bed to traverse the tool, and the cross-slide and compound rest allow for precise movements in and out and at angles. This allows for controlled depth-of-cut and feed rates, essential for consistent metal removal and achieving specific dimensions.

Can You Use One for the Other?

This is a common question for those looking to stretch their workshop capabilities. While there’s some overlap, it’s generally not recommended to try and perform heavy-duty operations of one on the other.

Using a Wood Lathe for Metal Work?

Technically, you might be able to turn very soft metals like aluminum or brass on a robust, heavy-duty wood lathe with appropriate tooling and extremely light cuts. However, it’s a risky proposition:

- Insufficient Power: Wood lathes usually lack the torque needed for efficient metal removal without bogging down.

- Vibration Issues: The lighter construction of many wood lathes will lead to excessive vibration when cutting metal, resulting in poor finishes and potential damage.

- Tooling Problems: Standard woodturning tools are not designed for metal cutting and will dull very quickly or break.

- Safety Risks: Higher speeds, potential for tool breakage, and insufficient rigidity create significant safety hazards.

In short, trying to turn metal on a wood lathe is usually inefficient, produces poor results, and is dangerous. You’re much better off investing in a proper metal lathe, even a small benchtop model, for metalworking projects.

Using a Metal Lathe for Wood Work?

This is somewhat more feasible, particularly for basic shaping or when very high precision is needed. You can turn wood on a metal lathe, but there are caveats:

- Speed: Metal lathes don’t typically reach the high RPMs ideal for smooth wood finishes, especially on smaller pieces. You might experience tear-out.

- Chip Evacuation: Metal chip guards and coolant systems are not designed for wood dust, which can be a fire hazard and make a mess.

- Tooling: You’d need to acquire specific woodturning tools, as metal cutting bits are unsuitable for efficient wood shaping. Holding these by hand on a metal lathe carriage is awkward and unsafe. Using them in the tool post is also not ideal for typical woodturning techniques.

- Dust and Mess: Woodworking produces fine dust, which can infiltrate the precise mechanisms of a metal lathe and cause wear over time.

While you could technically sand or do very basic cuts on wood with a metal lathe, it’s inefficient and not what the machine is designed for. The specialized tools and techniques of woodturning are best performed on a wood lathe.

Choosing the Right Lathe for You

The biggest factor in deciding between a wood lathe and a metal lathe is, unsurprisingly, the material you intend to work with. If your passion lies in crafting beautiful bowls, intricate spindles, or decorative wooden objects, a wood lathe is your tool.

If you dream of making precise metal parts, custom hardware, model engine components, or modifications for machinery, then a metal lathe is essential. Even hobbyists can benefit greatly from smaller benchtop metal lathes, which offer capabilities far beyond what a wood lathe can provide for metal.

Table: Wood Lathe vs. Metal Lathe – Key Differences at a Glance

| Feature | Wood Lathe | Metal Lathe |

|---|---|---|

| Primary Material | Wood | Metals (Steel, Aluminum, Brass, etc.) |

| Construction | Lighter to moderately heavy duty; materials may include cast iron, steel tubing. | Heavy duty, very rigid; primarily thick cast iron or steel. |

| Spindle Speed | High (e.g., 300 – 4,000+ RPM) | Low to moderate (e.g., 30 – 2,000 RPM) |

| Motor Power | Varies, typically fractional to a few horsepower. | Varies, often higher horsepower for size, with more torque. |

| Tooling | Handheld chisels, gouges, scrapers. | Rigidly held cutting bits (HSS, carbide) in a tool post. |

| Tool Engagement | Tool rest (body leverage) | Carriage, cross-slide, compound rest (mechanical feed) |

| Precision | Moderate to good; focus on form and finish. | High precision; essential for dimensional accuracy. |

| Vibration Resistance | Moderate | Very High |

| Typical Projects | Bowls, platters, spindles, pens, lamp bases, artistic shapes. | Shafts, bushings, threaded parts, custom fittings, gears, model components. |

Frequently Asked Questions (FAQ)

What is the main difference between a wood lathe and a metal lathe?

The main difference is the material they are designed to work with. Wood lathes are built for softer wood, often operating at higher speeds with hand-held tools. Metal lathes are robust machines designed for harder metals, using precisely controlled cutting tools and operating at lower speeds with much greater force and rigidity.

Can I turn metal on a wood lathe?

It’s generally not recommended. Most wood lathes lack the necessary power, rigidity, and precise control to safely and effectively cut metal. Trying to do so can lead to poor results, damage to the machine, and significant safety risks.

Can I turn wood on a metal lathe?

Yes, you can turn wood on a metal lathe, especially for basic shaping or when high precision is needed. However, it’s less efficient due to lower speeds and different tooling requirements. It also produces fine dust that can be hard on a metal lathe’s mechanisms.

Why do metal lathes run at slower speeds?

Metal lathes run slower to manage the heat generated during cutting, prevent tool wear, control chip formation, and maintain accuracy. Higher speeds would cause overheating, chatter, and unsafe conditions when cutting dense materials.

What kind of tools are used on each lathe?

Wood lathes use chisels, gouges, and scrapers, which are typically held by hand. Metal lathes use rigid cutting tools (tool bits made of HSS or carbide) mounted in a tool post on the carriage, allowing for controlled mechanical feed and depth of cut.

How much more expensive is a metal lathe than a wood lathe?

Generally, a metal lathe tends to be more expensive than a wood lathe of comparable quality and size. This is due to the heavier construction, precision machining, more powerful motors, and complex gearing or electronic speed controls required for metalworking.

What are the safety concerns for each type of lathe?

Wood lathe safety focuses on flying chips, secure workpieces, and avoiding entanglement with rotating parts at high speeds. Metal lathe safety involves handling sharp metal chips, entanglement risks at lower speeds, and managing heat and potential coolant hazards, alongside precise control over powerful cuts.

Conclusion

Understanding the distinctions between a wood lathe and a metal lathe is crucial for any aspiring maker or machinist. It’s not just a matter of what you’re turning, but how you’re turning it. The robust construction, lower speeds, precise tooling, and powerful drive systems of a metal lathe are designed for the demands of metalwork, ensuring accuracy and reliability. Conversely, the higher speeds and versatile, often hand-held tooling of a wood lathe are perfect for the art of shaping wood. By recognizing these fundamental differences—from the heavy-duty bed of a metal lathe to the familiar tool rest of a wood lathe—you can make an informed decision for your workshop. This knowledge empowers you to select the right machine to bring your creative visions to life, safely and effectively, whether you’re crafting a delicate wooden bowl or a precise metal gear.