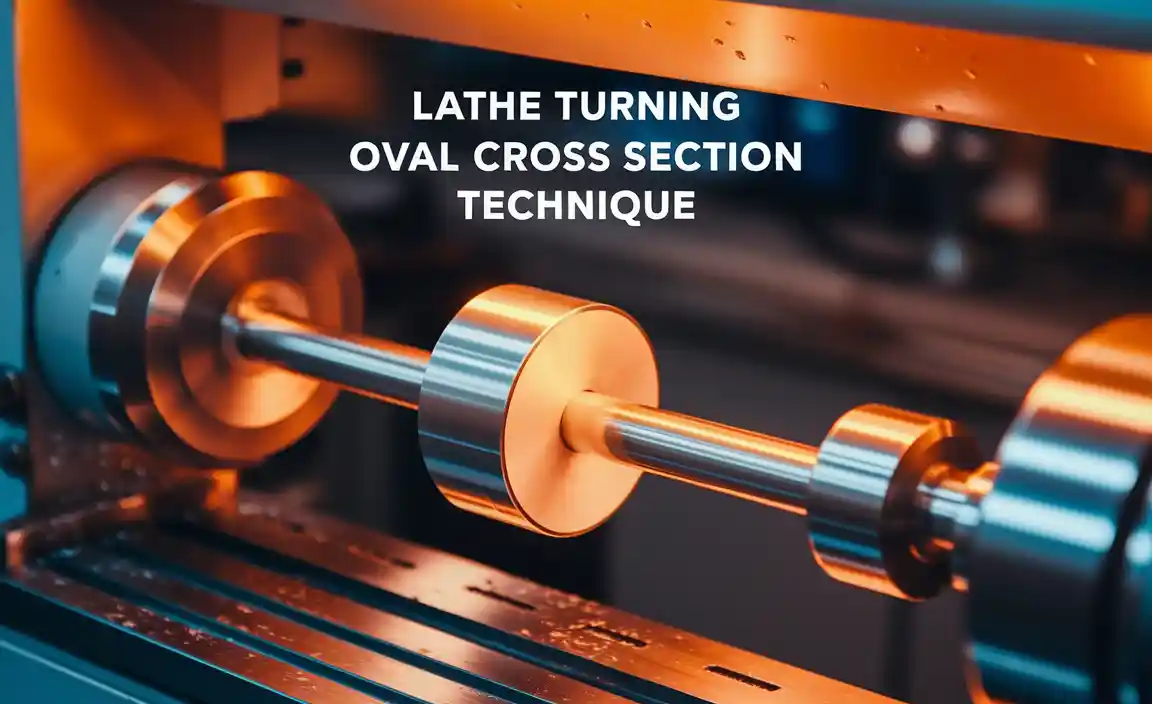

A 1/8″ carbide end mill, particularly one designed for titanium, is a powerful tool for precise machining. It offers excellent strength, high material removal rates (MRR), and durability, making it ideal for working with tough materials like Grade 5 titanium. Choosing the right one ensures cleaner cuts and extends tool life.

Hey folks, Daniel Bates here from Lathe Hub! Ever stared at a piece of stubborn titanium and wondered how to get those clean, precise cuts on your mill? It can feel a bit daunting, right? Especially when you’re starting out. You’ve got this fantastic 1/8″ carbide end mill, maybe even one promising to tackle titanium, but getting it to perform like a champ requires knowing a few key things. We’ll break down exactly what makes a 1/8″ carbide end mill a winner for titanium, especially those with a 1/2″ shank and standard length designed for high material removal rates (MRR). Forget the frustration; by the end of this guide, you’ll feel confident shaping that tough metal.

Understanding Your 1/8″ Carbide End Mill for Titanium

So, why all the fuss about a 1/8″ carbide end mill, especially when we talk about titanium? It boils down to a few critical factors that make this specific tool so effective for certain jobs. Think of it as the perfect handshake between the tool’s design and the material’s stubborn nature.

Carbide, in general, is a super hard material. This means it can handle high temperatures and wear better than many other cutting tool materials. When you’re machining something as tough as titanium (especially Grade 5, which is incredibly common and strong), you need a tool that won’t give up the ghost after a few minutes. A carbide end mill is your go-to for this kind of heavy lifting.

Now, let’s zoom in on the 1/8″ size. This diameter is fantastic for detailed work. It allows for intricate shapes, small features, and precise profiling. While it might not be your first choice for hogging out massive amounts of material, it’s invaluable for the fine-tuning and detailed machining that often follows roughing passes or is required for specific parts. For those tight spots or delicate designs, a 1/8″ end mill is often the only tool that will fit and do the job correctly.

When we add the “1/2 inch shank” specification, we’re talking about the part of the end mill that fits into your milling machine’s collet or tool holder. A 1/2″ shank is a very common size, offering good rigidity and holding power. For a 1/8″ cutting diameter, a 1/2″ shank provides excellent stability, reducing chatter and improving the surface finish of your workpiece, which is crucial when working with materials like titanium that can be prone to vibration.

“Standard length” is also important. It tells you the overall length of the tool and the length of the flutes (the spiraled cutting edges). A standard length is usually a good balance between reach and rigidity. Too short, and you might not be able to reach certain areas. Too long, and it can flex more, leading to chatter and poor finish, especially at higher speeds and feeds.

Finally, the magic ingredient for tackling titanium: “high MRR” (Material Removal Rate). This means the end mill is designed to efficiently cut through the material, taking away a good amount of metal in each pass without overheating or breaking. For titanium, this usually involves specific flute geometry, high-quality carbide grades, and often specialized coatings.

Why Titanium is a Tough Nut to Crack

Before we dive deeper into the end mill itself, let’s quickly touch on why titanium is such a unique material to machine. Understanding this helps us appreciate why specific tools and techniques are necessary.

- High Strength-to-Weight Ratio: Titanium is incredibly strong for its weight. This strength also means it resists cutting forces.

- Low Thermal Conductivity: Unlike aluminum or mild steel, titanium doesn’t transfer heat well. This means the heat generated during cutting stays concentrated right at the cutting edge. This can quickly lead to tool wear and even tool failure.

- Tendency to Work Harden: As titanium is cut, the surface layers can become harder. This “work hardening” makes subsequent cuts more difficult and increases wear on the cutting tool.

- Gummy Nature: Titanium can be “gummy,” meaning it tends to stick to the cutting tool, leading to chip welding and a poor surface finish.

Because of these properties, machining titanium requires tools that are exceptionally hard, sharp, and can handle high temperatures, while also employing strategies to manage heat and chip evacuation. This is precisely where a well-designed 1/8″ carbide end mill shines.

Key Features of a Proven Titanium Carbide End Mill (1/8″ Shank 1/2″)

When you’re looking for a 1/8″ carbide end mill specifically for titanium with a 1/2″ shank and designed for high MRR, there are several features you should pay close attention to. These aren’t just fancy terms; they directly impact performance and longevity.

Carbide Grade and Coating

The type of carbide and any coating applied are paramount for titanium machining.

- Sub-Micron or Micro-Grain Carbide: These are incredibly fine-grained carbides. The finer the grain, the harder and stronger the cutting edge. This allows the end mill to resist wear and chipping when encountering the abrasive nature of titanium.

- Advanced Coatings: For titanium, coatings are not just for show; they are functional necessities.

- TiAlN (Titanium Aluminum Nitride) or AlTiN (Aluminum Titanium Nitride): These are extremely popular and effective coatings for titanium. They form a hard, heat-resistant ceramic layer upon application and oxidation. This layer acts as a barrier, preventing heat from transferring into the carbide substrate and reducing friction. They also provide excellent wear resistance.

- ZrN (Zirconium Nitride): Sometimes used, offering good lubricity and heat resistance, though often less performant than TiAlN for titanium alloys.

- DLC (Diamond-Like Carbon): While excellent for lubricity and wear, DLC coatings can sometimes be too brittle for the shock loads encountered in some milling operations on titanium. However, advancements are being made.

Flute Geometry

The design of the cutting edges, or flutes, is critical for efficient chip removal and preventing chip welding.

- High Helix Angle (e.g., 30-45 degrees): A higher helix angle helps to “screw” the chips up and out of the cutting zone more effectively. Since titanium chips can be stringy and prone to welding, good chip evacuation is vital to prevent recutting chips and overheating.

- 2 or 3 Flutes (for Titanium): While 4-flute end mills are common for general-purpose finishing, they can sometimes struggle with chip evacuation in gummy materials like titanium, leading to chip recutting and poor finish or tool breakage. For titanium, especially with a 1/8″ diameter, 2 or 3 flutes are often preferred. They provide more space between flutes for chip clearance, allowing for higher feed rates and better heat management. Some specialized 3-flute “high-performance” or “hi-feed” end mills are specifically designed for materials like titanium.

- Sharp Cutting Edges: The cutting edges on an end mill for titanium need to be exceptionally sharp yet robust enough not to chip. This often means precision grinding and careful manufacturing.

- Center Cutting: For plunging operations, ensure the end mill is center cutting. This means the flutes extend to the very end of the tool, allowing it to plunge straight down into the material.

Shank and Overall Dimensions

As mentioned, the shank and length contribute significantly to performance.

- 1/2″ Shank Diameter: This provides rigidity needed for a 1/8″ cutting diameter. A larger shank relative to the cutting diameter generally means less deflection and vibration.

- Standard Length: A balance is key. Too short limits reach; too long increases flex. For a 1/8″ diameter, a standard length typically offers a good compromise for most benchtop or small milling machines. Check manufacturer specifications for “reach” and “effective cutting length.

Solid Carbide Construction

The “carbide” in carbide end mill means it’s made from solid cemented carbide. This is what gives it its hardness and resistance to thermal deformation, essential for high-speed machining and tough materials like titanium.

Choosing the Right 1/8″ Carbide End Mill for Your Needs

When you’re ready to buy, consider these factors to ensure you get the right tool:

Material Compatibility

Ensure the end mill is explicitly rated or recommended for titanium. While some “high-performance” or “all-purpose” end mills might handle titanium in a pinch, a tool designed for titanium will perform significantly better and last longer. Look for descriptions like “Titanium Grade 5,” “High-Temp Alloys,” or “Exotic Materials.”

For example, the Titanium Tool 1/8″ Carbide End Mill is often cited in discussions for its suitability with materials like Titanium Grade 5, emphasizing its high MRR capabilities.

Manufacturer Reputation

Stick with reputable manufacturers. Brands known for quality tooling (e.g., Milwaukee, Makita, Lakeshore Carbide, Widia, Sandvik Coromant, if budget allows for their professional lines) are more likely to adhere to strict manufacturing tolerances and use premium materials and coatings. For hobbyist or smaller setups, brands like Precise Bits or Melin Tool often offer good value. Always check reviews specific to machining titanium.

Cost vs. Value

A high-quality end mill designed for titanium won’t be the cheapest option. However, consider the long-term value. A good tool will cut cleaner, last longer, reduce scrap, and reduce frustration. Investing in a decent tool will save you money and headaches in the long run. A cheap, unbranded end mill is far more likely to fail catastrophically when pushing the limits, especially with tough materials.

Specific Application

Are you doing slotting, profiling, contouring, or facing? While a general-purpose end mill can do many things, specialized end mills (though less common in 1/8″ size) might exist for specific operations. For most beginners tackling titanium with a 1/8″ tool, a 2 or 3-flute, high-performance end mill with a TiAlN coating will be the most versatile and effective choice.

Using Your 1/8″ Carbide End Mill on Titanium: Best Practices

This is where the rubber meets the road! Simply having the right tool isn’t enough; you need to use it correctly. Machining titanium requires a different approach than softer metals. Here’s how to get the most out of your 1/8″ carbide end mill.

Speeds and Feeds: The Golden Ticket

This is arguably the most crucial aspect of machining titanium. Titanium requires lower surface speeds (SFM or SMM) and higher feed rates than aluminum or even steel. This might sound counter-intuitive, but it’s essential for several reasons:

- Heat Management: Lower speeds reduce the heat generated at the cutting edge.

- Chip Formation: Higher feed rates create thicker chips, which can carry heat away from the workpiece and cutting tool more effectively. Thin, wispy chips indicate you’re rubbing, not cutting, and generating excessive heat.

- Work Hardening: Taking a sufficient depth of cut and feed rate helps to get below the work-hardened layer.

Here’s a general guideline. Always consult your end mill manufacturer’s recommendations first! These are starting points:

Table: Starting Speeds and Feeds for 1/8″ Carbide End Mill on Grade 5 Titanium

| Operation | Surface Speed (SFM) | Chip Load per Tooth (IPR or mm/tooth) | Spindle Speed (RPM) | Feed Rate (IPM or mm/min) |

|---|---|---|---|---|

| Slotting / Contouring | 60 – 100 SFM (approx. 18-30 SMM) | 0.0005 – 0.002″ (approx. 0.013-0.05 mm) | (SFM 3.82) / Diameter = RPM (approx. 2300 – 3800 RPM for 1/8″) |

(Chip Load Flutes * RPM) = IPM (approx. 5 – 20 IPM for 2-flute) |

| Shoulder/Face Milling (light passes) | 50 – 80 SFM (approx. 15-24 SMM) | 0.0005 – 0.0015″ (approx. 0.013-0.038 mm) | (Approx. 1900 – 3000 RPM for 1/8″) | (Approx. 4 – 12 IPM for 2-flute) |

Note: These are generic starting points. Actual speeds and feeds depend heavily on your machine’s rigidity, coolant use, depth of cut, width of cut, and the specific grade and condition of the titanium. Running with adequate coolant is highly recommended.

To calculate Spindle Speed (RPM): RPM = (SFM × 12) / (π × Diameter in inches)

To calculate Feed Rate (IPM): IPM = RPM × Number of Flutes × Chip Load per Tooth (inches)

Depth and Width of Cut

When machining titanium, it’s often best to take lighter radial (width) and axial (depth) cuts than you might with softer materials. This helps to manage heat and reduce cutting forces.

- Radial Depth of Cut (RDOC): For slotting, aim for a much smaller width of cut than the end mill diameter. A 1/8” end mill might only cut effectively at a 1/16” (50%) or even 1/32” (25%) width of cut in titanium. Step-overs in profiling or contouring should also be conservative.

- Axial Depth of Cut (ADOC): This is the depth you plunge or cut down into the material. Start conservatively. For instance, with a 1/8″ end mill, you might start with an axial depth of cut of 1/8″ or even less, and increase it if the tool and machine can handle it without chatter or excessive heat. Full depth slotting can be very challenging. Consider helical milling or pocketing strategies where you incrementally remove material.

Coolant and Lubrication

Effective coolant is not optional when machining titanium. It plays a critical role in:

- Cooling: Preventing the cutting edge from overheating and extending tool life.

- Chip Evacuation: Flushing chips away from the cutting zone.

- Lubrication: Reducing friction between the tool and workpiece.

For titanium, a high-pressure coolant system is ideal. Flood coolant can help, but a focused stream directed right at the cutting edge is best. Specialized cutting fluids or sprays designed for high-temperature alloys can also be beneficial. Flood coolant systems can be purchased from various industrial suppliers, and many CNC machines come equipped with them. For manual machines, a proper flood coolant setup is a significant upgrade for tough materials.

If high-pressure coolant isn’t available, consider using a mist coolant system or a high-quality cutting paste/fluid applied directly to the cutting area. Air blast can help chip evacuation but doesn’t offer the cooling or lubrication benefits of liquid.

Rigidity is Key

Your milling machine setup needs to be as rigid as possible. Titanium exerts significant cutting forces. Ensure:

- Clean Tool Holder: The collet and tool holder must be clean and free of debris.

- Proper Tool Engagement: Ensure the end mill is inserted sufficiently into the collet for maximum support, but not so far that it risks hitting the workpiece or the bottom of a hole.

- Sturdy Machine Frame: A wobbly machine will vibrate, leading to chatter, poor finish, and broken tools.

- Secure Workholding: The workpiece must be clamped down extremely securely. Any movement here is disastrous.

Research from the National Institute of Standards and Technology (NIST) highlights the importance of understanding material properties and machining parameters for alloys like titanium to achieve optimal results and prevent issues like tool wear and chatter. Rigidity and precise control are consistently emphasized.