Quick Summary: A 1/8 inch carbide end mill, especially those designed for chatter reduction, is your best bet for clean G10 cuts. Look for features like variable helix or specific coatings to ensure smooth results and a chatter-free milling experience.

Hey everyone, Daniel Bates here from Lathe Hub! Chatter. It’s the enemy of a smooth finish on your milling projects, especially when working with tricky materials like G10. That frustrating chatter, that vibration that leaves nasty marks on your workpiece, can really put a damper on your progress. But don’t worry, it’s a common problem, and the solution is often simpler than you think. Today, we’re diving deep into how a specific tool—the 1/8 inch carbide end mill—can be your secret weapon against G10 chatter. We’ll cover why this size and material are perfect, what features to look for, and how to use it effectively so you can achieve those clean, professional-looking cuts you’re after. Stick around, and let’s get your milling projects running smoothly!

Why G10 Tests Your Milling Skills (And Your Tools)

G10. It’s a fantastic material: strong, lightweight, and an excellent electrical insulator. This makes it super popular for everything from knife scales and custom grips to electronic project enclosures and even aerospace components. However, when it comes to milling, G10 can be a bit… stubborn. It’s an abrasive composite material, essentially made of fiberglass cloth and epoxy resin. This composition means it can wear down standard tooling quickly, and worse, it’s prone to vibrating, which leads to that dreaded chatter.

When chatter shows up, it’s like a bad artist scribbling on your perfectly planned design. You get rough surfaces, burrs, and it can even weaken the part itself. For beginners, seeing this can be disheartening. It might feel like you’re doing something wrong, but often, it’s just a matter of selecting the right tool for the job. The 1/8 inch carbide end mill, when chosen wisely, addresses many of G10’s milling challenges head-on.

The 1/8 Inch Carbide End Mill: Your Chatter-Busting Hero

So, why is a 1/8 inch carbide end mill such a good choice for G10 and for reducing chatter?

Carbide vs. HSS: The Material Advantage

First off, let’s talk about carbide. Most beginner-friendly end mills might be made of High-Speed Steel (HSS). HSS is good, but carbide, specifically Tungsten Carbide, is significantly harder and more rigid. This increased hardness means it can withstand the abrasive nature of G10 much better than HSS, leading to longer tool life. Crucially for chatter, carbide’s rigidity also means it’s less prone to deflecting or vibrating under the cutting forces. This makes it a much more stable cutting tool, which is key to smooth, chatter-free cuts.

The Power of Small: Why 1/8 Inch?

Now, the 1/8 inch size. Smaller diameter end mills generally have a few advantages when dealing with chatter:

- Reduced Cutting Forces: A smaller tool removes less material at any given moment. This means lower cutting forces are exerted on the workpiece and the tool itself. Lower forces translate to less potential for vibration.

- Higher Spindle Speeds: Smaller end mills often allow your milling machine to run at higher spindle speeds (RPM). Higher RPMs can sometimes improve surface finish by allowing the tool to “skim” over the material rather than “hogging” it. For G10, finding that sweet spot in RPM is vital.

- Better Chip Evacuation: While it might seem counterintuitive, smaller flutes can sometimes lead to better chip evacuation in certain materials, preventing chips from recutting and causing surface issues.

- Detail and Control: For intricate cuts often found in G10 projects (like intricate grip patterns or precise enclosures), a 1/8 inch end mill offers excellent control and allows for fine detail work.

The 1/4 Inch Shank: A Common and Convenient Size

You’ll often find 1/8 inch end mills on a 1/4 inch shank. This is a very standard size for smaller end mills, meaning they fit common collets and holders found in many desktop and entry-level milling machines. It’s a practical size that balances rigidity of the shank with the cutting diameter of the bit.

Features That Fight Chatter: Beyond Just Size and Material

Just being a 1/8 inch carbide end mill isn’t the whole story. To truly conquer G10 chatter, you need to look for specific design features:

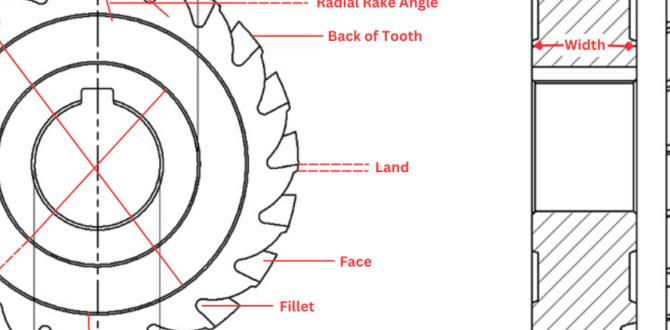

1. Variable Helix Angle

This is a game-changer for chatter reduction. Standard end mills have a uniform spiral flute angle (the helix). Variable helix end mills have flutes that are ground at slightly different angles along the length of the cutting edge.

Imagine a regular end mill like a drumbeat: thump-thump-thump. A variable helix end mill is more like jazz: thump-tah-thump-tah-thump.

This variation breaks up the harmonic vibrations that cause chatter. Instead of the tool hitting the material at the exact same spot and force with every rotation, the varied angles mean the cutting forces are distributed more randomly. This “scatters” the vibration, leading to a much smoother cut. If you see an end mill advertised with a “variable helix” or “anti-vibration” design, it’s a strong candidate for tough materials like G10.

2. Number of Flutes

For milling plastics and composites like G10, the number of flutes is important:

- 2 Flutes: Often preferred for plastics and softer materials. They provide good chip clearance, which is crucial for preventing melting or gumming up. The fewer flutes mean more space for chips to escape.

- 3 Flutes: A good balance. They offer better strength and can handle slightly higher feed rates than 2-flute end mills, but chip clearance can be more of a concern in gummy materials.

- 4+ Flutes: Generally better for harder metals where chip evacuation is less critical and tool rigidity is paramount. For G10, sticking to 2 or 3 flutes is usually the best bet.

For chatter reduction on G10, a 2-flute end mill is often a prime choice due to its excellent chip evacuation capabilities, which aids in smooth cutting.

3. End Mill Coatings

Coatings add another layer of performance and wear resistance. While not always strictly necessary for G10, certain coatings can help:

- Zirconium Nitride (ZrN): This gold-colored coating is excellent for abrasive materials and high-temperature applications. It provides good lubricity and wear resistance, helping to keep the edge sharp and the cutting smooth.

- Titanium Nitride (TiN): A more common, yellowish coating that offers good general-purpose wear resistance.

- Uncoated: For softer materials, an uncoated carbide end mill can perform well. However, for G10’s abrasiveness, a coated tool will likely last longer and perform more consistently.

Look for coatings specifically designed for plastics or composites if possible, but ZrN is a very reliable choice.

4. End Cut Style

Most end mills are “flat” on the end, meaning they cut straight down. For certain operations, you might see end mills with slightly rounded or ball-shaped ends. For general profile milling and pocketing G10, a standard flat-end design is usually what you’ll use and is perfectly capable.

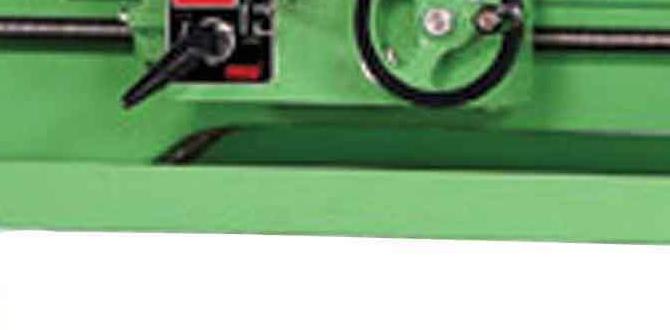

Setting Up for Success: Tooling and Machine Parameters

Once you have the right 1/8 inch carbide end mill, setting it up correctly is crucial. This involves your machine, your collet, your speeds, and your feeds.

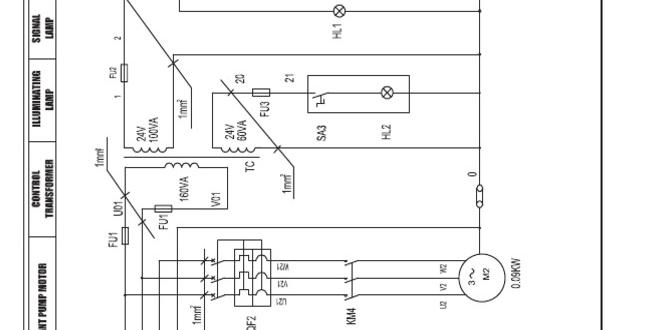

1. The Collet Chuck: Precision is Key

A good quality collet chuck is, in my opinion, a must-have for any serious milling. Why? Because it grips the end mill shank much more precisely and concentrically than a standard drill chuck. A drill chuck typically grips the shank off-center, introducing runout (wobble). This runout is a direct invitation to chatter and poor surface finish.

For a 1/4 inch shank end mill, you’ll need a 1/4 inch ER collet or a similar system. Ensure your collet and the collet nut are clean and free of debris. Install the end mill so it’s securely held, with minimal overhang (the distance the end mill sticks out past the collet). A shorter overhang makes the tool more rigid and less prone to vibration.

You can learn more about collet systems from resources like the Machining Training website, which often has great explanations on precision workholding:

2. Speeds and Feeds: The Balancing Act

This is arguably the most critical part of avoiding chatter, and it’s where many beginners struggle. For G10, you’re looking for a balance between cutting efficiently without overheating or overloading the tool, and moving fast enough to avoid dwelling in one spot too long, which can also cause vibration.

General starting points for a 1/8 inch 2-flute carbide end mill in G10 might look something like this. These are just starting points, and you’ll need to adjust based on your specific machine and end mill.

| Parameter | Recommended Value (Starting Point) | Notes |

|---|---|---|

| Spindle Speed (RPM) | 15,000 – 25,000 RPM | Higher RPMs can help achieve a better surface finish and reduce chip load, but ensure your spindle can reach these speeds. |

| Feed Rate (IPM/min) | 8 – 20 IPM (Inches Per Minute) | This is the speed the tool moves through the material. Adjust based on sound and surface finish. |

| Chip Load per Flute | 0.001″ – 0.002″ | This is the thickness of material removed by each flute per revolution. This is a very important factor you can calculate or find in manufacturer’s data. |

| Depth of Cut (DOC) | 0.010″ – 0.050″ | Start shallow and increase gradually if possible. Small step-downs reduce vibration risk. |

| Width of Cut (WOC) | 0.020″ – 0.060″ | For pocketing, don’t try to remove too much width in one pass. |

Understanding Chip Load: The “Chip Load per Flute” is a fundamental concept. For a 1/8 inch (0.125″) 2-flute end mill, if you’re aiming for a chip load of 0.002″, your feed rate would be:

Feed Rate = Number of Flutes × Chip Load per Flute × Spindle Speed (RPM)

Feed Rate = 2 × 0.002″ × 20,000 RPM = 80 IPM

This calculation highlights that “IPM” values depend heavily on RPM and chip load. Always aim for healthy chip loads that are not too small (which can rub and overheat) or too large (which can overload the tool and cause chatter).

The Sound Test: As you mill, listen carefully to the machine. A smooth, consistent humming sound is good. A high-pitched squeal or a grinding, chattering noise is bad. If you hear chatter, reduce your feed rate slightly or adjust your depth of cut. Sometimes, even a slight change in spindle speed can make a difference.

Use a Feed Calculator: Many tool manufacturers and CNC software providers offer online feed rate calculators. These can be invaluable for getting reasonable starting points. For example, a tool manufacturer like Precise Bits often provides excellent resources for CNC routing, which applies well here:

Precise Bits Feed Rate Calculator

3. Depth and Stepovers

Depth of Cut (DOC): Always err on the side of caution. Taking shallow passes (e.g., 0.010″ to 0.050″) is much better for G10 than trying to hog out a deep cut. Shallow passes reduce the stress on the end mill and the machine, significantly lessening the chance of chatter.

Stepover (Width of Cut – WOC): When performing pocketing or profiling, the “stepover” is the distance the tool moves sideways between passes. A smaller stepover (e.g., 20-40% of the tool diameter) generally results in a smoother surface finish and less chatter than a large stepover.

Practical Steps: Milling G10 with Your 1/8″ End Mill

Let’s walk through a typical scenario. Imagine you need to cut out a shape from a sheet of 1/8 inch thick G10.

- Design Your Part: Create your design in CAD software. Ensure your tool diameter (1/8 inch) is accounted for.

- Select Your End Mill: Choose a 1/8 inch 2-flute carbide end mill with a variable helix design. A ZrN coating would be ideal. Ensure it’s a “standard length” or has a reasonable flute length for your operation.

- Secure Your G10: Clamp your G10 sheet firmly to your milling machine bed. Use a good surface, like a spoilboard or a precision vise, to prevent movement. Double-sided tape can work for very light cuts, but clamps are recommended for G10.

- Set Up Your Machine:

- Load the end mill into a clean collet chuck. Ensure it’s tightened securely and there’s minimal overhang.

- Set your Z-axis zero point accurately on the surface of the G10.

- Program Your Toolpath:

- Set your spindle speed (e.g., start at 20,000 RPM if your machine can handle it).

- Calculate your feed rate based on desired chip load (e.g., target 0.0015″ chip load, giving a feed rate of around 60 IPM for 2 flutes at 20,000 RPM).

- Set your depth of cut to be shallow (e.g., 0.020″).

- Set your stepover if doing pocketing (e.g., 0.040″ for a 1/8″ tool).

- Initiate the Cut:

- Start your spindle and let it come up to speed.

- Begin your cutting operation.

- Listen and Observe: Pay close attention to the sound and the surface finish.

- If you hear chatter, immediately pause the machine or be ready to stop. Try reducing the feed rate by 10-20%.

- If the finish is rough, try a slightly shallower depth of cut or a smaller stepover.

- If you’re getting excessive heat or chips are melting, you might need to increase feed rate slightly or reduce spindle speed a bit to increase chip load.

- Complete the Cut: Once you have stable parameters that produce a smooth cut, let the machine complete the operation.

- Check Your Work: Inspect the cut edges for smoothness and accuracy.

Troubleshooting Common G10 Milling Issues

Even with the right tools, sometimes you hit a snag. Here are common issues and how to fix them:

Issue: Chatter Marks / Rough Surface Finish

- Cause: Too high feed rate, too deep of a cut, worn tool, excessive runout, unstable workholding, wrong spindle speed.

- Solution:

- Reduce feed rate.

- Reduce depth of cut.

- Check and reduce tool overhang.

- Ensure your collet chuck is centered and the collet is clean.

- Firmly clamp your G10.

- Experiment with slight increases or decreases in spindle speed.

- Try a variable helix end mill if you aren’t already.

Issue: Melting or Gumming Up

This is common with plastics and composites. It happens when the material melts instead of being cleanly cut.

- Cause: Too low spindle speed, too high feed rate (rubbing instead of cutting), insufficient chip load, poor