Carbide end mills, especially the 1/8 inch size, are crucial for precise machining. Achieving long tool life is the key to cost-effectiveness and consistent results, even for small-diameter cuts. This guide shows you how to get the most out of your 1/8 inch carbide end mills.

Hey there, workshop friends! Daniel Bates here from Lathe Hub, and I get it. When you’re starting out with milling, or even if you’ve been around the block a few times, figuring out how to make your tools last can feel like a puzzle. Especially with those tiny, fiddly 1/8 inch carbide end mills. They’re amazing for detail work, but if they chip or wear out too fast, it can get frustrating and expensive. We’ve all been there, staring at a dull cutter and wondering what went wrong. But don’t worry! With a few smart practices, you can dramatically extend the life of your 1/8 inch carbide end mills. We’ll dive into the best ways to use them so they perform reliably, cut cleanly, and save you money in the long run. Stick around, because we’re about to unlock the secrets to long tool life!

Why Your 1/8 Inch Carbide End Mill’s Life Matters

That little 1/8 inch carbide end mill is a workhorse for intricate tasks. Whether you’re engraving delicate patterns, creating small slots, or working with hard materials like Inconel 718, this size is often your go-to. But its small diameter also makes it more delicate. When it wears out or breaks prematurely, it’s not just about the cost of a new tool. It means lost production time, potential damage to your workpiece, and the frustration of stopping your project. Understanding what affects tool life is the first step to mastering your milling operations. It’s about precision, efficiency, and making your hard-earned cash go further.

Understanding Carbide End Mills for Beginners

Let’s break down what makes a carbide end mill special. Unlike High-Speed Steel (HSS) tools, carbide is a much harder material. This means it can cut faster and handle tougher jobs, including heat-treated steels and exotic alloys. However, carbide is also more brittle. So, while it’s tough, it can chip if subjected to sudden shocks or improper cutting forces. For a 1/8 inch end mill, this is even more critical because the flutes (the cutting edges) are so small.

When we talk about a “1/8 inch carbide end mill 10mm shank standard length for Inconel 718 long tool life,” we’re specifying a few key things:

- 1/8 Inch Diameter: This is the cutting part of the tool.

- 10mm Shank: This is the part that goes into your milling machine’s collet or holder. A 10mm shank is common and provides a good grip for this diameter.

- Standard Length: Refers to the overall length of the end mill. Some are longer for deeper cuts, but standard is typical for general use.

- Carbide: The material, known for its hardness.

- For Inconel 718: This is a superalloy that’s notoriously difficult to machine. Using the right end mill is critical here.

- Long Tool Life: The primary goal we’re aiming for.

Essential Factors for Long Tool Life

Getting long life out of your 1/8 inch carbide end mill isn’t magic. It’s a combination of using the right settings, the right technique, and taking care of your tool. Here are the key elements:

1. Proper Speeds and Feeds

This is probably THE most important factor. Speeds and feeds dictate how fast the tool spins (speed) and how fast it moves through the material (feed rate). Too fast, and you’ll overheat and dull the tool. Too slow, and you can rub and cause premature wear. For a 1/8 inch carbide end mill, especially in tough materials:

- Surface Speed (SFM): Carbide generally likes to run faster than HSS, but for small tools in hard materials, it’s often better to err on the side of caution. For Inconel 718, you might be looking at surface speeds anywhere from 30-100 SFM, depending on the specific grade of carbide and the milling strategy.

- Chip Load: This is the thickness of the material removed by each tooth of the end mill with each revolution. For 1/8 inch carbide end mills, especially in Inconel, chip load is critical. A typical starting point might be around 0.001 to 0.003 inches per tooth. Too small a chip load causes the tool to rub instead of cut, leading to excessive heat and rapid wear. Too large, and you risk chipping the carbide or overloading the machine.

- Revolution Per Minute (RPM): Once you have your desired Surface Speed (SFM) and know the diameter of your end mill (1/8 inch = 0.125 inches), you can calculate the RPM using the formula: RPM = (SFM 3.25) / Diameter. For example, at 50 SFM with a 0.125-inch diameter: RPM = (50 3.25) / 0.125 = 1300 RPM. However, always consider the chip load and your machine’s capabilities.

- Feed Rate (IPM): Calculated by: Feed Rate = RPM Number of Teeth Chip Load. For a 2-flute end mill, cutting at 1300 RPM with a 0.002-inch chip load: Feed Rate = 1300 2 0.002 = 5.2 inches per minute (IPM).

Tip: Always consult manufacturer data for specific speeds and feeds if available. For tough materials like Inconel, starting conservatively and gradually increasing is wise.

2. Material Considerations

Machining Inconel 718 requires a different approach than machining aluminum. Inconel is known for:

- Work Hardening: It becomes harder the more you cut it. This means you need to maintain adequate chip loads to prevent the material from work-hardening ahead of the tool.

- Low Thermal Conductivity: Heat doesn’t dissipate well, so it concentrates at the cutting edge, increasing wear.

- Abrasiveness: It’s tough and abrasive, which wears down cutting edges faster.

For Inconel, you’ll typically want:

- Specific End Mill Geometry: Look for end mills designed for high-temperature alloys. These often have a higher helix angle (around 30-45 degrees) for better chip evacuation and reduced cutting forces.

- Dedicated Carbide Grade: Uncoated carbide can work, but coatings like TiAlN (Titanium Aluminum Nitride) or AlTiN (Aluminum Titanium Nitride) can significantly improve performance and tool life in tough, hot materials by reducing friction and increasing heat resistance.

- Conservative Speeds, Adequate Chip Load: As mentioned earlier, this is key. Focusing on maintaining a good chip load is paramount to avoid work hardening.

Learning about different material machining properties can be a deep dive, but understanding that Inconel is “sticky” and hardens itself is crucial. For more on machining these challenging materials, resources like the Machinery Magazine often have detailed guides.

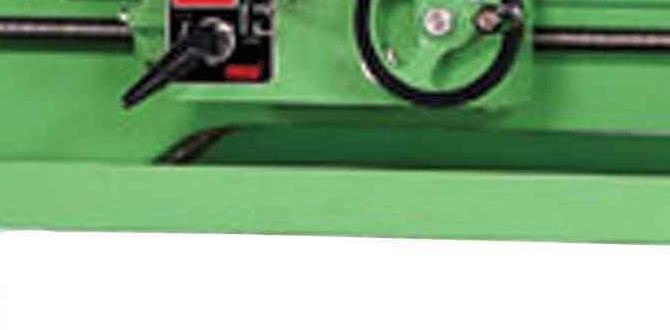

3. Proper Tool Holding and Machine Rigidity

A strong, rigid setup is vital. A wobbly tool holder or a flexy machine spindle will lead to chatter, inconsistent cuts, and premature tool breakage, especially with a small 1/8 inch tool.

- Collet Quality: Use a high-quality, precision collet that fits your 10mm shank tightly and symmetrically. A worn or cheap collet won’t hold the end mill securely, leading to runout and chatter.

- Tool Holder Condition: Ensure your tool holder is clean, undamaged, and provides good runout (the amount the tool deviates from a perfect axial path). Aim for less than 0.0005 inches of runout.

- Machine Rigidity: Can your milling machine handle the forces involved, especially when plunging or taking aggressive cuts? Ensure gibs are properly adjusted and there’s no excessive play in the machine’s axes. A small, delicate tool is more susceptible to vibrations.

4. Coolant and Chip Evacuation

Heat is the enemy of carbide. Proper cooling and ensuring chips get out of the way are critical.

- Flood Coolant: For materials like Inconel, a good flood coolant or high-pressure coolant system is highly recommended. It not only cools the cutting edge but also lubricates the cut and helps flush chips away.

- Mist Coolant (MQL – Minimum Quantity Lubrication): A fine mist of coolant and air can also be effective, especially for smaller operations, and is more environmentally friendly.

- Air Blast: In some non-critical applications or for certain materials, a strong blast of air can help clear chips and offer some cooling.

- Chip Breakers: Some end mills have chip-breaking features, but with a 1/8 inch tool, efficient chip evacuation is more about the cutting strategy and coolant.

Ensure your machine’s coolant system is working effectively and that the nozzle is positioned to blast coolant directly at the cutting zone.

5. Cutting Strategy and Depth of Cut

How you approach a cut matters. For small end mills and tough materials, it’s rarely a good idea to take the widest possible cut or the deepest plunge.

- Axial Depth of Cut (DOC): This is how deep the end mill cuts into the material along its length. For Inconel with a 1/8 inch end mill, you’ll typically want a shallow axial DOC. A common rule of thumb for full slotting is to use a DOC that’s only about 25-50% of the tool diameter. For finishing passes, it might be even shallower.

- Radial Depth of Cut (WOC – Width of Cut): This is how much of the tool’s diameter is engaged in the material. For true slotting, WOC is 100% of the diameter. For features like pockets, you might use a stepped approach or climb milling with a reduced WOC.

- Climb Milling vs. Conventional Milling: Climb milling (where the cutter rotates in the same direction as the feed) is often preferred for tough materials as it can reduce cutting forces and improve surface finish. Conventional milling (where the cutter rotates against the feed) can sometimes be better for very hard materials or to prevent excessive tool deflection. For most beginner scenarios aiming for tool life and good finish on Inconel, climb milling is a good starting point with a shallow DOC.

- Pecking/Ramping: When plunging straight down, especially in deep holes, a plunging end mill can generate a lot of heat and chip packing. Techniques like “peck drilling” (plunging a short distance, retracting to clear chips, and repeating) or “ramping” (feeding into the material at an angle) can significantly improve tool life and prevent tool breakage.

For a comprehensive guide on milling strategies, the National Tooling & Machining Association (NTMA) provides excellent resources on basic machining practices, which can be found on their official website.

6. Tool Coating Selection

Coatings aren’t just for looks; they’re functional layers that protect the carbide.

- Uncoated: Best for softer materials or when very specific micro-finishes are required that a coating might interfere with.

- TiN (Titanium Nitride): A basic, gold-colored coating offering some wear resistance and reduced friction. Good for general-purpose machining of steels and aluminum.

- TiCN (Titanium Carbonitride): Darker gray/blue, harder than TiN, better for abrasive materials and higher speeds.

- TiAlN / AlTiN (Titanium Aluminum Nitride / Aluminum Titanium Nitride): These are excellent choices for high-temperature alloys like Inconel. They form a protective aluminum oxide layer at high temperatures, providing superior heat resistance and wear life. These are often dark purple or black.

For 1/8 inch carbide end mills machining Inconel 718, a TiAlN or AlTiN coating is almost a necessity for achieving any reasonable tool life.

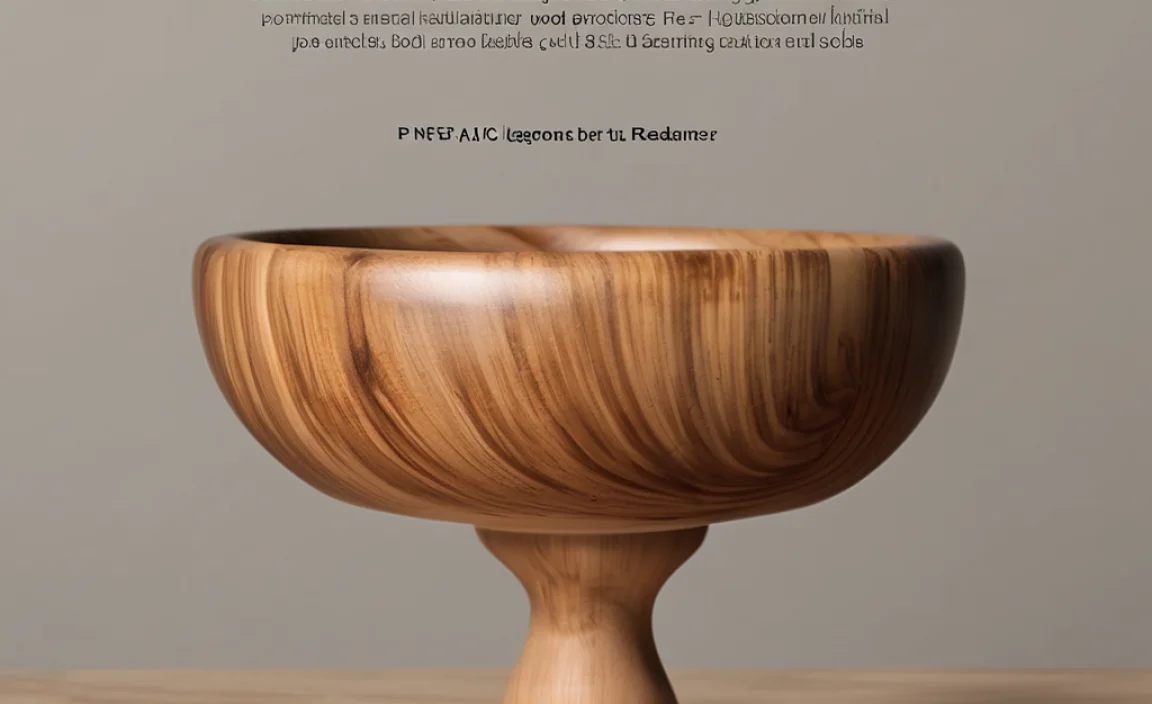

7. End Mill Geometry and Flute Count

Not all 1/8 inch end mills are created equal. Consider these aspects:

-

- Number of Flutes:

- 2-Flute: Offers good chip clearance and is often preferred for plunge cuts and slotting, especially in softer or stringy materials like aluminum. For tough materials like Inconel, a 2-flute can provide adequate chip room.

- 3-Flute: A good all-around choice that balances cutting ability with chip evacuation.

- 4-Flute: Best for finishing in steels or when a smoother surface finish is desired. Chip evacuation can be more restricted in tough materials, making them less ideal for heavy roughing of Inconel.

- Number of Flutes:

For 1/8 inch Inconel work, a 2-flute or 3-flute end mill with a higher helix angle is often recommended to help manage chip load and clearance.

- Helix Angle: Higher helix angles (e.g., 30-45 degrees) generally provide smoother cutting, better chip evacuation, and reduced cutting forces. This is beneficial for tough materials.

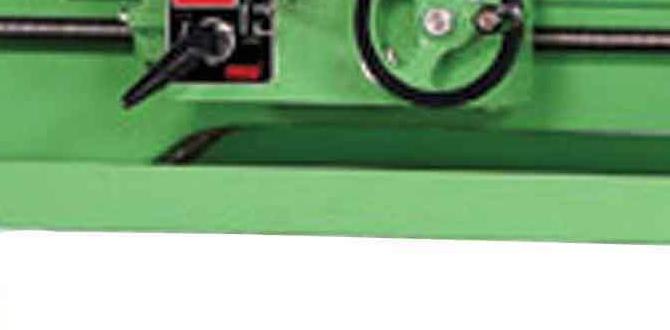

- Corner Radius/Ball Nose: A square end mill has a sharp 90-degree corner, while a ball nose has a rounded tip. Corner radii can add strength to the cutting edge, but for intricate detailing, a ball nose might be required.

- Overall Length: Standard length is common, but for deeper pockets, you might need an extended length version. Be aware that longer tools are more prone to deflection and vibration.

Step-by-Step: Machining with a 1/8 Inch Carbide End Mill for Long Life

Let’s put it all together into a practical, step-by-step approach. This assumes you’re working with Inconel 718 or a similar tough alloy on a reasonably capable milling machine.

Step 1: Select the Right Tool

- Choose a 1/8 inch carbide end mill.

- Ensure it has a TiAlN or AlTiN coating.

- Opt for a 2-flute or 3-flute design with a 30-45 degree helix angle.

- If possible, select one designed specifically for high-temperature alloys.

- Verify it has a 10mm shank for your collet.

Step 2: Set Up for Rigidity

- Insert the end mill into a clean, high-quality collet.

- Secure the collet in the machine’s spindle.

- Ensure your machine’s gibs are properly adjusted to minimize play.

- Check for any obvious vibration or looseness in the machine’s ways or spindle bearings.

Step 3: Determine Speeds and Feeds (with Caution)

This is an iterative process. We’ll start conservatively.

- Target Surface Speed (SFM): Start low for Inconel and TiAlN coating, around 50 SFM.

- Calculate RPM: For a 0.125″ tool at 50 SFM: RPM = (50 3.25) / 0.125 = 1300 RPM.

- Target Chip Load: Begin with a very conservative chip load, say 0.0015 inches per tooth for a 2-flute end mill.

- Calculate Feed Rate (IPM): Feed Rate = 1300 RPM 2 flutes * 0.0015 ipt = 3.9 IPM.

- Axial Depth of Cut (DOC): For initial roughing passes, aim for about 0.060 inches (roughly 50% of the tool diameter).

- Radial Depth of Cut (WOC): For slotting, this is 0.125 inches. For pocketing, consider starting with a smaller WOC, like 0.050 inches, and climb milling.

Important Note: These are starting points! You MUST monitor the cut and adjust.

Step 4: Ensure Adequate Cooling and Lubrication

- Turn on your flood coolant or MQL system.

- Position the nozzle to directly target the cutting zone.

Step 5: Execute the Cut (Cautiously