For cutting acrylic with precision and a smooth finish, a 3/16 inch carbide end mill with an 8mm shank is your go-to tool. Its sharp edges and durable carbide construction slice cleanly through acrylic without melting or chipping, making it essential for achieving professional results in your projects.

Working with acrylic can sometimes feel like a puzzle, especially when it comes to getting clean, precise cuts. Many beginners encounter frustrating issues like melted plastic, chipped edges, or rough surfaces when they try to mill acrylic. It’s a common hurdle, but thankfully, there’s a simple solution that can make all the difference. By choosing the right tool, you can transform your acrylic projects from frustrating to fantastic. This guide will walk you through why a specific type of end mill is so vital for acrylic and how to use it effectively. Get ready to achieve those smooth, glass-like finishes you’ve been dreaming of!

Why a 3/16 Inch Carbide End Mill with an 8mm Shank is Your Acrylic Best Friend

When you’re milling materials like plastic, especially acrylic, the tool you use is paramount. Acrylic is a thermoplastic, meaning it softens and melts when heated. Traditional tools can generate a lot of heat, leading to that dreaded melted mess. This is where a carbide end mill shines, and a specific size combination becomes incredibly useful.

A carbide end mill is made from tungsten carbide, an extremely hard and wear-resistant material. This hardness allows it to maintain a sharp cutting edge even at high speeds and temperatures. For acrylic, this means it can cut through the material quickly without generating excessive heat that would cause melting. The sharpness of carbide is key to a clean cut.

Now, let’s talk about the size: a 3/16 inch diameter with an 8mm shank. Why this specific combination? The 3/16 inch diameter is a versatile size for many acrylic projects, offering a good balance between detail capability and material removal rate. It’s large enough to cut efficiently but small enough for intricate designs. The 8mm shank is also a common size found on many popular desktop CNC machines and routers. Having this combination ensures compatibility with a wide range of equipment, making it an accessible and practical choice for hobbyists and small workshops.

The “standard length” typically refers to a tool that isn’t excessively long, which helps maintain rigidity and reduce the chance of chatter or vibration. For acrylic, rigidity is crucial for a clean cut. A tool with minimal runout (the wobble of the cutting edge as it spins) also contributes significantly to a smooth finish. A high-quality 3/16 inch carbide end mill with an 8mm shank is designed for precisely this kind of performance.

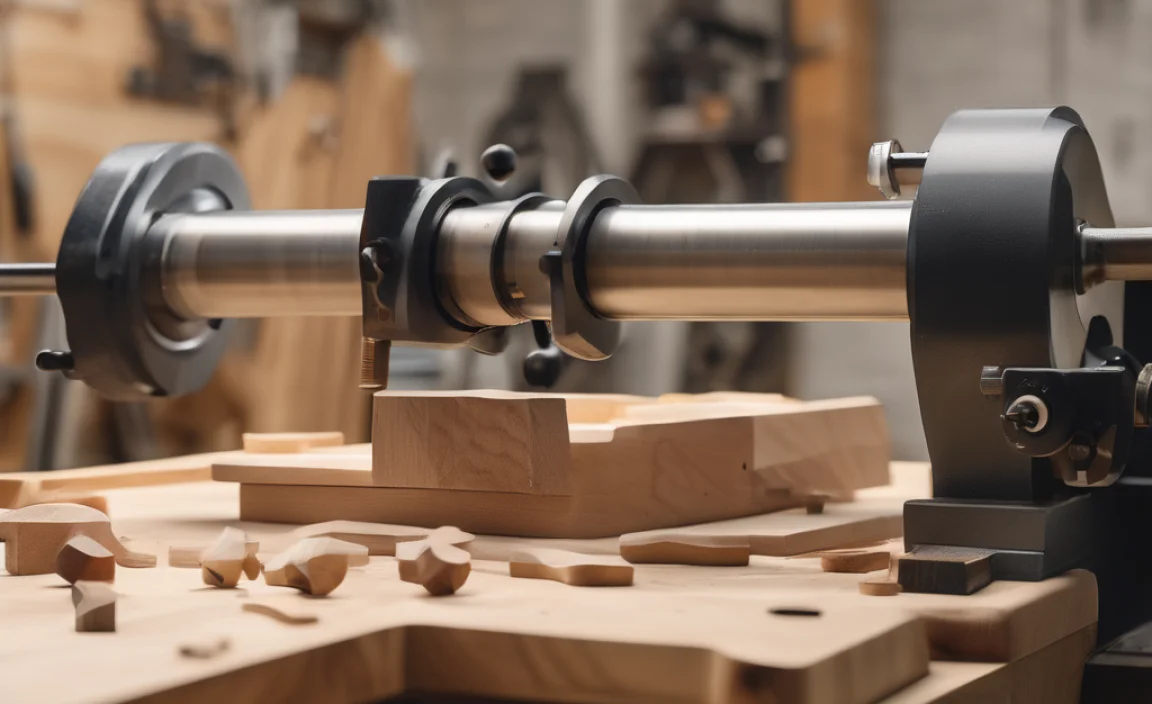

Understanding End Mill Basics

Before we dive deeper into acrylic specifics, let’s quickly recap what an end mill is and how it works. An end mill is a type of milling cutter that has a shank (the part that goes into the tool holder) and cutting edges along its sides and at its tip. Unlike drill bits that cut only at the tip, end mills can cut on their sides, allowing them to make slots, pockets, and profiles. They spin at high speeds, and their sharp edges shear away material as they move through the workpiece.

End mills come in various materials, geometries, and sizes. The material, like carbide or HSS (High-Speed Steel), determines hardness and heat resistance. The geometry (number of flutes, helix angle) affects chip evacuation and cutting performance. And, of course, the diameter and length are critical for matching the tool to the specific task and machine capabilities.

Carbide for Acrylic: The Science Behind the Smoothness

Acrylic, chemically known as Polymethyl methacrylate (PMMA), behaves differently than many metals or woods when cut. Its relatively low melting point and tendency to chip easily make it a material that demands careful tool selection and machining parameters. This is precisely why carbide end mills are so often recommended:

- Heat Dissipation: Carbide’s high thermal conductivity allows it to transfer heat away from the cutting edge and into the chips more effectively than HSS. This is crucial for preventing the acrylic from melting and re-solidifying.

- Edge Retention: The extreme hardness of carbide means it stays sharp for longer. A sharp tool cuts cleanly and produces less heat. A dull tool is more likely to rub, generating heat and leading to melting or poor cut quality.

- Cutting Speed: Carbide can withstand higher cutting speeds. This allows you to remove material faster, and in the case of acrylic, a higher speed can sometimes lead to a cleaner cut if managed correctly, provided chip evacuation is good.

- Reduced Chip Welding: Chip welding (where chips fuse to the cutting edge) is a common problem with plastics. Sharp carbide tools, especially those designed for plastics, minimize this by creating clean breaks in the material.

For acrylic, you’ll often find end mills specifically designed for plastics. These might have fewer flutes (like a 2-flute end mill), a sharper cutting angle, and polished flutes to help chips slide away more easily. These features contribute to reducing friction and heat, which are the enemies of a good acrylic cut.

Key Features of the 3/16 Inch 8mm Shank Carbide End Mill for Acrylic

When you’re looking for the perfect tool for your acrylic tasks, consider these specific features that make a 3/16 inch carbide end mill with an 8mm shank so effective:

- Material: Solid Carbide is the non-negotiable choice for acrylic. Look for high-quality grades of tungsten carbide.

- Diameter: 3/16 inch (approximately 4.76mm) is a versatile size. It’s ideal for detailed work like engraving, cutting out small parts, or creating smooth profiles for sign-making, displays, or model components.

- Shank Diameter: 8mm is a very common shank size for many smaller CNC routers and milling machines, often found on desktop models. Ensure your machine’s collet or tool holder can accept an 8mm shank.

- Number of Flutes: For acrylic, 1 or 2 flute end mills are generally preferred.

- 1-Flute: Excellent for plastic and soft materials because they offer maximum chip clearance. This means chips are easily removed, reducing the risk of melting and recutting.

- 2-Flute: A good compromise, offering decent chip clearance while providing more cutting edges for a potentially smoother finish and slightly faster material removal than a single flute.

- Coating: While not strictly necessary for acrylic, some coatings can further improve performance. Uncoated carbide is usually perfectly adequate, but if you see polished flutes or specialized plastic coatings, they can be beneficial.

- Helix Angle: A higher helix angle (e.g., 30-45 degrees) can help lift chips away from the cut more efficiently, which is beneficial for plastics.

- End Cut Type: Most standard end mills are “flat bottom” or “square” end mills. For acrylic, this is usually what you’ll need. Center-cutting capability means the end mill can plunge directly into the material without needing to pre-drill a hole.

- Runout: Low runout is critical for a smooth finish. This refers to how much the cutting edge deviates from spinning perfectly true. A tool with low runout will produce cleaner, more accurate cuts with less vibration.

The combination of these features, particularly being made of carbide, having a suitable flute count for chip evacuation, and low runout, makes this specific end mill type a standout choice for achieving excellent results on acrylic.

When to Use a Carbide End Mill for Acrylic vs. Other Tools

Understanding when to reach for your carbide end mill for acrylic projects is as important as knowing what it is. Here’s a breakdown:

Ideal Scenarios for a 3/16 Inch Carbide End Mill:

- CNC Routing: This is where this end mill truly excels. For precise cuts, engraving, cutting out intricate shapes for signs, displays, or parts.

- Pocketing and Slotting: Creating recesses or channels within acrylic sheets for functional or decorative purposes.

- Profile Cutting: Cutting out the exact outer shape of a design from a sheet of acrylic.

- Engraving: The fine detail possible with a 3/16 inch end mill makes it suitable for shallow engraving of text or graphics.

- Projects Requiring Smooth Edges: When a glass-like, polished edge is desired straight off the mill.

When to Consider Alternatives or Other Tools:

- Very Thick Acrylic (Over 1/2 inch): While a 3/16 inch end mill can work, you might need multiple passes or consider a larger diameter end mill if you’re removing a lot of material quickly. However, for precision, the 3/16 inch is still excellent.

- Very Fine Detail (<1/16 inch): For extremely intricate work, you might need a smaller diameter end mill (e.g., 1/16 inch or smaller), but the 3/16 inch offers a good balance for most common tasks.

- Rough Cuts or Material Removal: If your primary goal is rapid material removal and finish quality isn’t paramount, a different tool or strategy might be employed on less critical surfaces.

- Laser Cutting: For some projects, laser cutting might be a faster or more suitable alternative, especially for very thin acrylic or complex 2D shapes. However, laser cutting can leave a slightly melted edge that may need post-processing, whereas routing with a good end mill can produce a clean edge directly.

- Traditional Woodworking Saws/Routers: While sometimes used, standard woodworking router bits designed for wood can melt acrylic. If using a standard router, ensuring it’s a bit specifically designed for plastics or using very shallow passes is essential. The carbide end mill designed for CNC is optimized for this.

For general-purpose milling of acrylic on a CNC machine, the 3/16 inch 8mm shank carbide end mill is usually the workhorse tool. Its ability to provide both precision and a clean finish makes it indispensable.

Essential Setup Considerations for Milling Acrylic

Getting the right tool is only half the battle. To achieve those perfect acrylic cuts, you need to set up your machine and your project correctly. Here are the key considerations:

1. Workholding: Secure That Acrylic!

Acrylic can be slippery, and vibration can easily dislodge it. You need to secure your workpiece firmly. Common methods include:

- Double-sided tape: For thinner sheets, strong double-sided tape can be surprisingly effective.

- Vacuum hold-down: If your CNC has a vacuum table, this is an excellent method.

- Clamps: Use clamps, but be cautious not to overtighten and crack the acrylic, especially near the edges. Place clamps strategically to avoid interfering with the end mill’s path.

- Fixtures: Custom-made fixtures can provide the most secure hold for repetitive tasks.

Always ensure the acrylic is held flat against the spoilboard or work surface to prevent the end mill from digging too deep on one side.

2. Feeds and Speeds: Finding the Sweet Spot

This is perhaps the most critical aspect of milling acrylic without melting. Finding the right balance between how fast the end mill spins (spindle speed, RPM) and how fast it moves through the material (feed rate, inches per minute or mm/minute) is key. There’s no single “magic number” as it depends on your specific CNC machine rigidity, the exact type of acrylic, and the end mill, but here are general guidelines:

- Spindle Speed (RPM): Generally, moderate to high RPMs are used, but not excessively high, as this can increase heat. Start in the range of 15,000 – 24,000 RPM.

- Feed Rate (IPM or mm/min): This is crucial. You want to move fast enough to allow the cutting edge to shear the material rather than rub and melt it. Use a relatively aggressive feed rate compared to how deep you are cutting. A good starting point might be 30-60 inches per minute (approx. 750-1500 mm/min) for a 3/16 inch end mill, but always test.

- Depth of Cut (DOC): For acrylic, it’s best to take lighter cuts. A common recommendation is to cut no more than 0.1 to 0.2 inches (2.5 to 5mm) per pass. This allows the tool to cut cleanly and manage chip evacuation. For very thin acrylic, the DOC will simply be the thickness of the material.

Rule of Thumb: Always perform test cuts on scrap material! Listen to the sound of the cut. A clean, crisp sound is good. A high-pitched squeal or a dragging, melting sound is bad. Visually inspect the chips and the cut edge.

You can find good resources for starting feeds and speeds online, such as those provided by CNC machine manufacturers or tool suppliers. Websites like the

National Institute of Standards and Technology (NIST) Wood Machining Fundamentals offer insights into material cutting principles that can be applied.

3. Chip Evacuation: Clearing the Way

As mentioned, melted plastic is the enemy. Ensuring chips are promptly removed from the cutting area is paramount:

- Air Blast: A stream of compressed air directed at the cutting zone is highly effective in blowing chips away and helping to cool the material. Many CNC machines have an air blast attachment for this.

- Mist Coolant: For more demanding applications or if air blast isn’t enough, a mist coolant system can provide lubrication and cooling. Be aware that this can make a mess and may not be suitable for all workshop environments.

- Chip Breaking Passes: Sometimes, software can be set up to make very short retracts during a long cut to break up the chips.

- Tool Geometry: Using end mills with polished flutes and appropriate helix angles helps chips climb out of the cut.

4. Dust Collection: Safety First

While acrylic dust isn’t as hazardous as some metal dusts, it can still be an irritant and create a mess. Ensure your CNC router or mill is connected to an effective dust collection system.

5. Machine Rigidity: Essential for Clean Cuts

The more rigid your machine, the less vibration and chatter you’ll experience. This directly translates to cleaner cuts and less heat buildup. Solid machines are crucial for working successfully with plastics like acrylic. A wobbly machine will struggle to produce good results, no matter how good your end mill is.

Step-by-Step Guide: Milling Acrylic with Your 3/16 Inch 8mm Shank Carbide End Mill

Let’s walk through the process of setting up and making a cut on acrylic. Assume you have your design ready in CAM software and your CNC machine is prepared.

Step 1: Design and CAM Setup

Create your design in CAD software and then import it into CAM software (like VCarve Pro, Fusion 360, Easel, etc.).

- Select Tool: Choose your 3/16 inch 8mm shank carbide end mill from the tool library. If you don’t have it, create a new tool entry with its specifications (diameter, shank size, number of flutes, material).

- Set Cutting Paths: Define your toolpaths. For cutting through acrylic, you’ll typically use “profile” toolpaths.

- Specify Passes: Set the stepdown (depth per pass) to be conservative (e.g., 0.1 inches or 2.5mm).

- Define Tabs (if needed): For parts that might shift or get pushed out of place by the end mill, add small “tabs” in your CAM software to hold them in place until the final finish pass or until you’re ready to remove them.

- Add Lead In/Out: Use small, gentle lead-in moves to help the end mill enter the material without slamming into it.

Step 2: Prepare Your Machine and Material

Secure the Acrylic: Place your acrylic sheet on your CNC machine’s bed. Use your chosen workholding method (tape, clamps, vacuum) to ensure it is completely stable and flat. Double-check that the entire area to be cut is free of debris.

Install the End Mill: Carefully insert the 3/16 inch carbide end mill into your router or spindle collet. Ensure it is seated correctly and tightened securely. Verify it’s the correct 8mm shank size for your collet.

Set the Zero Point (Origin): You’ll need to set your machine’s X, Y, and Z zero points.

- X and Y: Jog the spindle to a known starting point on your material (e.g., a corner) and set your X and Y zero there.

- Z Zero: This is critical. Carefully jog the spindle down until the tip of the end mill just touches the surface of the acrylic or your setup block. Safely set your Z zero at this point. You might use a touch plate or manually find