Have you ever wondered how machines like metal lathes work? These tools can create amazing shapes from metal. One important part of their design is the lathe gear ratio. It may sound complex, but it’s really interesting!

The lathe gear ratio helps determine how fast the metal spins and cuts. Different ratios can lead to different results. Imagine trying to carve a perfect bowl from a chunk of metal. Would you use a fast or slow speed? The answer lies in understanding the lathe gear ratio.

Did you know that a simple change in this gear can make a big difference in your project? Even experts agree that knowing how to adjust the gear ratio is essential for success. In the world of metalworking, it’s not just about having the best tools, but also knowing how to use them effectively.

So, if you’re curious about crafting with metal or looking to improve your skills, keep reading! You’ll discover the secrets behind lathe gear ratios and how they can help you create amazing projects. Let’s dive in!

Understanding Lathe Gear Ratio For Metal Lathe Gear Usage

Lathe Gear Ratio: Unlocking the Power of Metal Lathes

Lathe gear ratio plays a crucial role in metal lathes. This ratio affects how fast and powerful the lathe spins. A higher gear ratio means faster cuts but less torque. Imagine trying to ride a bike uphill with the wrong gears! Understanding these ratios helps you choose the right settings for your project. Did you know that a simple change in gear can lead to smoother finishes or more accurate cuts? Mastering lathe gear ratios can transform your metalworking skills!What is a Lathe Gear Ratio?

Definition of gear ratio in the context of metal lathes.. Importance of gear ratio for machining precision..A gear ratio is like a dance between the gears on a metal lathe. It tells us how many times the motor turns to move the cutting tool. Think of it as a measure of speed and precision. A good gear ratio can make the difference between a perfect cut and a tangled mess that looks like a cat got into a yarn basket. Proper gear ratios help machines work accurately, which is crucial for creating smooth surfaces and exact shapes. Remember, a well-tuned lathe with the right gear ratio is a happy lathe!

| Gear Ratio | Effect on Speed | Effect on Torque |

|---|---|---|

| High Ratio | Increases Speed | Decreases Torque |

| Low Ratio | Decreases Speed | Increases Torque |

How Gear Ratio Affects Metal Lathe Performance

Discussion on speed control and torque.. Impact of gear ratios on surface finish and cutting efficiency..Understanding how gear ratios work can really make your metal lathe dance! When you adjust the gear ratio, you can control the speed and torque. A higher gear ratio means more speed, but less torque. Think of it as riding a bike—the more you pedal, the faster you go, but it can be hard to climb those hills. This balance affects the surface finish. With the right ratio, your cuts will be smooth like butter! Good gear ratios enhance cutting efficiency, making your work more fun.

| Gear Ratio | Speed | Torque | Surface Finish |

|---|---|---|---|

| High | Fast | Low | Rough |

| Medium | Balanced | Medium | Smooth |

| Low | Slow | High | Very Smooth |

Finding the sweet spot between speed and torque can turn your lathe into a work of art. Experiment, have fun, and watch your projects shine!

Calculating Gear Ratios for Metal Lathes

Stepbystep method to calculate gear ratios.. Examples of calculations using common lathe setups..Understanding how to calculate gear ratios is handy for metal lathe users. Follow these steps for simple calculations:

- Identify the drive gear size (number of teeth).

- Identify the driven gear size.

- Use the formula: Gear Ratio = Driven Gear Teeth ÷ Drive Gear Teeth.

For example, if a lathe has a drive gear with 10 teeth and a driven gear with 30 teeth:

Gear Ratio = 30 ÷ 10 = 3. This means the driven gear moves three times slower than the drive gear. Understanding this can help in choosing the right settings for various projects.

What is a lathe gear ratio?

The lathe gear ratio helps determine how fast the lathe spins the workpiece. A lower ratio means slower speeds while cutting. It is worthwhile to know this to achieve the best results.

Benefits of Optimizing Gear Ratio

Increased efficiency and productivity in machining.. Reduced wear and tear on lathe components..Optimizing the gear ratio of a metal lathe is like finding the perfect recipe for your favorite cake—just right for a great outcome! With the right gear ratio, you can crank up efficiency and get machining jobs done faster. Who doesn’t like to speed things up? Plus, fewer hours working means less wear on your lathe parts. This means fewer broken bits and a happier wallet! It’s all about keeping things running smooth like butter on toast!

| Benefit | Description |

|---|---|

| Increased Efficiency | Faster machining speeds lead to quicker project completion. |

| Reduced Wear | Lower stress on components means longer-lasting equipment. |

Common Mistakes to Avoid with Gear Ratios

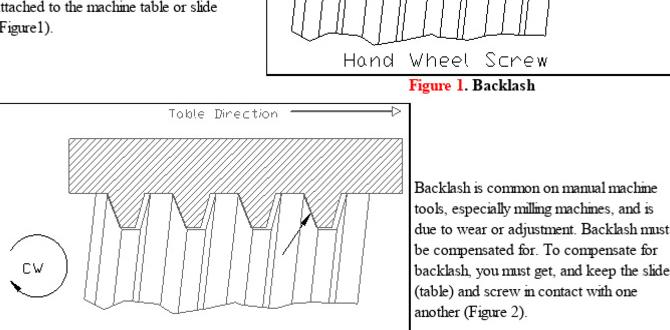

Misapplying gear ratios leading to machining errors.. Ignoring manufacturer specifications and guidelines..Many beginners make mistakes with gear ratios. Misusing these ratios can lead to big problems in machining. If you set the wrong ratio, your final product may not fit together right.

Another common error is ignoring what the manufacturer says. Following their guidelines is important for safe and effective use. This can save time and materials. Check these points to avoid mistakes:

- Always calculate the right gear ratio.

- Read the manual carefully.

- Test settings before using them.

Remember, a small mistake can cost you a lot!

What are the key benefits of correct gear ratios?

Correct gear ratios increase accuracy and efficiency. They help your lathe work smoothly and reduce wear on parts.

Upgrading or Modifying Lathe Gear Ratio

When to consider upgrades or modifications.. Potential products or modifications available for enhancing gear ratios..Upgrading or modifying your lathe gear ratio can make a big difference. You should consider these changes if you want more speed or better torque. Sometimes, some parts need replacing to get the most out of your machine.

When looking for products, think about:

- New gear sets

- Speed reducers

- Motor upgrades

- Changeable pulley systems

These upgrades can help you create better projects and work more efficiently. They improve how your lathe performs, making your tasks easier and more fun!

When Should You Upgrade Your Lathe Gear Ratio?

You should upgrade when you need better speed or torque.

Case Studies: Successful Gear Ratio Implementations

Realworld examples of companies optimizing lathe gear ratios.. Analysis of the outcomes and improvements in productivity..Many companies have found big wins by tweaking their lathe gear ratios. For instance, Factory X reduced cutting time by 30% by adjusting their gear setup. This change let them produce more parts daily without working overtime – because who doesn’t love extra free time?

Company Y saw a 25% boost in productivity, simply by finding the sweet spot in their gear ratios. By making these changes, workers were happier too! Happy workers make happy products. Below is a summary of these exciting outcomes:

| Company | Productivity Increase | Cutting Time Reduction |

|---|---|---|

| Factory X | — | 30% |

| Company Y | 25% | — |

These real-world examples show how small changes can lead to big results. It seems that optimizing lathe gear ratios isn’t just smart; it can be downright fun, too!

Future Trends in Lathe Gear Design and Technology

Innovations in gear ratio technologies for metal lathes.. Predictions on how these advancements will shape the industry..New ideas in gear ratio technologies for metal lathes are exciting! Smart designs are making machines faster and more precise. These gears help lathes use less power, which is both good for the planet and costs less to run. Soon, we may see:

- Advanced materials that last longer

- More efficient designs that save time

- Easy-to-use digital controls for better accuracy

These trends will shape the industry by allowing manufacturers to create more complex parts and increase production speed. The future looks bright for metal lathe gear designs!

How will these innovations affect the industry?

Innovations will lead to faster production, lower costs, and better quality in metalworking. Companies will adapt to meet customer needs more effectively.

Conclusion

In summary, understanding lathe gear ratios helps you use a metal lathe more effectively. Gear ratios impact speed and torque, influencing your project’s outcome. By knowing how to adjust them, you can achieve better results. Keep exploring lathe techniques and don’t hesitate to practice what you’ve learned. Happy turning! For more tips, check out a local workshop or online resources!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Gear Ratios And Metal Lathe Gears:Lathe gear ratios help us change how fast the lathe turns. A higher number makes it spin slower, while a lower number makes it faster. This is important when we want to cut different materials. By adjusting the gears, we can make our work easier and get better results. Understanding gear ratios helps us be better at using a lathe!

Sure! Please provide the question you’d like me to answer, and I’ll respond accordingly.

What Is The Significance Of Gear Ratios In Metal Lathes, And How Do They Affect Machining Precision?Gear ratios in metal lathes are really important. They help us control how fast the metal turns. This control helps us make better cuts and shapes. When the lathe spins at the right speed, we get smoother and more precise results. So, having the right gear ratio means we can create high-quality work.

How Do You Calculate The Gear Ratio For A Specific Lathe Setup And What Factors Should Be Considered?To calculate the gear ratio for a lathe, you need to look at the number of teeth on the gears. First, count the teeth on the driving gear (the one that’s moving) and the driven gear (the one that is turned). Then, you divide the number of teeth on the driven gear by the number of teeth on the driving gear. Also, think about the speed you want and the type of work you will do, as this can change your setup.

What Are The Differences Between Fixed And Variable Gear Ratios In Metal Lathes, And When Should Each Be Used?Fixed gear ratios have a set number of speeds. You can’t change them while working. This works well for simple jobs where you don’t need different speeds. Variable gear ratios let you change the speed while you work. This is great for more complex tasks, like when metal needs different speeds to cut well.

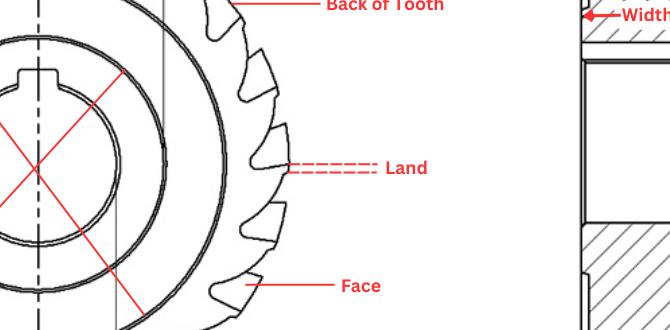

How Do Different Gear Materials Impact The Performance And Longevity Of Lathe Gears?Different materials make lathe gears work better or worse. For example, metal gears are strong and last a long time. Plastic gears are lighter but may wear out faster. If the gear is tough, it can handle more work and last longer. So, choosing the right material helps gears work well and last for a long time.

What Are Common Problems Associated With Gear Ratios In Metal Lathes, And How Can They Be Mitigated?Gear ratios in metal lathes help control speed and power. Common problems include incorrect settings, which can cause slow or uneven cuts. To fix this, you can double-check the gear settings before starting. Also, keep the machine clean and well-oiled to ensure smooth operation. If something seems off, ask a teacher or expert for help.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Gear Ratios And Metal Lathe Gears:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe gear ratios help us change how fast the lathe turns. A higher number makes it spin slower, while a lower number makes it faster. This is important when we want to cut different materials. By adjusting the gears, we can make our work easier and get better results. Understanding gear ratios helps us be better at using a lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll respond accordingly.”}},{“@type”: “Question”,”name”: “What Is The Significance Of Gear Ratios In Metal Lathes, And How Do They Affect Machining Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Gear ratios in metal lathes are really important. They help us control how fast the metal turns. This control helps us make better cuts and shapes. When the lathe spins at the right speed, we get smoother and more precise results. So, having the right gear ratio means we can create high-quality work.”}},{“@type”: “Question”,”name”: “How Do You Calculate The Gear Ratio For A Specific Lathe Setup And What Factors Should Be Considered?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calculate the gear ratio for a lathe, you need to look at the number of teeth on the gears. First, count the teeth on the driving gear (the one that’s moving) and the driven gear (the one that is turned). Then, you divide the number of teeth on the driven gear by the number of teeth on the driving gear. Also, think about the speed you want and the type of work you will do, as this can change your setup.”}},{“@type”: “Question”,”name”: “What Are The Differences Between Fixed And Variable Gear Ratios In Metal Lathes, And When Should Each Be Used?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Fixed gear ratios have a set number of speeds. You can’t change them while working. This works well for simple jobs where you don’t need different speeds. Variable gear ratios let you change the speed while you work. This is great for more complex tasks, like when metal needs different speeds to cut well.”}},{“@type”: “Question”,”name”: “How Do Different Gear Materials Impact The Performance And Longevity Of Lathe Gears?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different materials make lathe gears work better or worse. For example, metal gears are strong and last a long time. Plastic gears are lighter but may wear out faster. If the gear is tough, it can handle more work and last longer. So, choosing the right material helps gears work well and last for a long time.”}},{“@type”: “Question”,”name”: “What Are Common Problems Associated With Gear Ratios In Metal Lathes, And How Can They Be Mitigated?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Gear ratios in metal lathes help control speed and power. Common problems include incorrect settings, which can cause slow or uneven cuts. To fix this, you can double-check the gear settings before starting. Also, keep the machine clean and well-oiled to ensure smooth operation. If something seems off, ask a teacher or expert for help.”}}]}