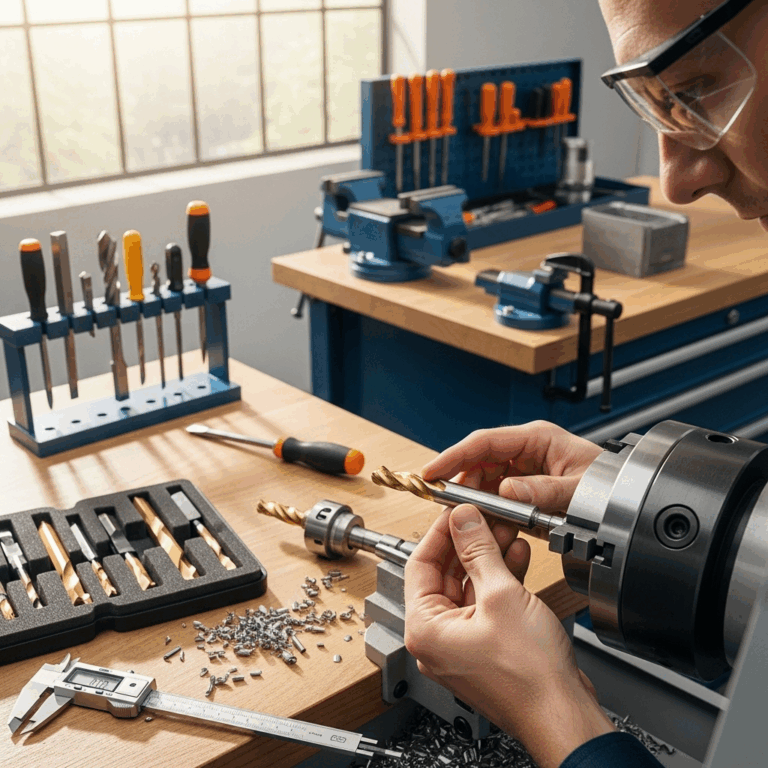

To achieve effortless brass chip evacuation with a 1/8-inch carbide end mill, understanding feed rates, flute design, and proper cooling is key. This guide simplifies the process, ensuring clean cuts and preventing frustrating chip buildup for beginner machinists.

Working with soft metals like brass on a milling machine can sometimes feel like wrestling a sticky dough. Tools can clog, chips can weld themselves back onto your workpiece, and your perfectly planned cut can turn into a messy, frustrating experience. This is especially true when you’re using a small tool, like a 1/8-inch carbide end mill. Getting those tiny brass shavings to clear out of the flutes is crucial for smooth operation and a good finish. Don’t worry, though! It’s not as complicated as it sounds. With a few simple adjustments and understandings, you can make chip evacuation a breeze, even for delicate brass projects. We’ll walk through exactly what you need to know to conquer this common milling challenge.

This guide will break down how to effectively manage chips when milling brass with a 1/8-inch carbide end mill. We’ll cover everything from choosing the right tool and settings to helpful techniques that will make your brass machining jobs much cleaner and more successful. Get ready to turn those frustrating chip-clogged moments into smooth, satisfying cuts!

Why Chip Evacuation Matters with Brass

Brass is a fantastic material for many projects. It machines relatively easily, looks great, and is often found in artistic creations, plumbing fittings, and musical instruments. However, it also has a tendency to be “gummy” or “sticky” when machined. This means that as the cutting tool removes material, the softened brass can easily cling to the cutting edges and clog the flutes of your end mill.

When chips don’t evacuate properly, several problems can arise:

- Poor Surface Finish: Clogged flutes act like dull tools, leading to rough surfaces on your workpiece.

- Tool Breakage: Extra pressure from packed chips can cause the small, delicate 1/8-inch end mill to snap.

- Heat Buildup: Chips acting as insulation can trap heat around the cutting edge, leading to premature tool wear and potential workpiece damage.

- Increased Cutting Forces: The machine has to work harder, which can lead to chatter and inaccuracies.

- Recutting Chips: Clogged flutes can push chips back into the cut, creating a rough surface and potentially damaging the workpiece or tool.

For a 1/8-inch end mill, which is quite small, these issues are magnified. The flutes are narrow, offering less space for chips to travel. Therefore, mastering chip evacuation with this size tool, especially in brass, is fundamental to successful machining.

Choosing the Right 1/8-Inch Carbide End Mill for Brass

Not all 1/8-inch carbide end mills are created equal, especially when you’re targeting a gummy material like brass. The design of the end mill plays a significant role in how well it clears chips. Look for these features:

- Number of Flutes: For softer materials like brass, it’s generally best to use end mills with fewer flutes. A 2-flute end mill is often ideal for brass. The larger chip gullets (the space between the flutes) allow chips to escape more easily. While 3-flute and 4-flute cutters provide a better finish in harder metals, they can pack up with chips much faster in brass.

- Flute Geometry: Look for end mills with a polished or bright flute finish. This smoother surface reduces friction and helps chips slide out more readily. Some end mills designed for plastics or non-ferrous metals might have special flute shapes that further aid chip evacuation.

- Coating: For brass, an uncoated carbide end mill is often preferred. Coatings can sometimes increase friction or build-up in gummy materials. However, some specific coatings might be beneficial, so it’s worth researching if a specialized non-ferrous metal coating exists.

- Type: A standard 2-flute end mill is a good starting point. For specific applications, you might encounter stub-length or extended-reach variations. A stub-length end mill will have a shorter flute length for added rigidity, which can be beneficial.

A common and effective choice for your needs would be a “carbide end mill 1/8 inch 1/4 shank stub length for brass chip evacuation.” The stub length contributes to rigidity, crucial for small cutters, and the design is often optimized for soft materials.

Key Machining Parameters for Brass with a 1/8″ End Mill

Setting the correct spindle speed and feed rate is paramount for managing chips and achieving good results when milling brass. These parameters dictate how quickly the tool spins and how fast it is advanced into the material.

Spindle Speed (RPM)

Spindle speed is measured in revolutions per minute (RPM). For carbide tools machining softer metals like brass, a general guideline is to use a relatively high spindle speed, but not excessively high. Too slow, and you might rub rather than cut. Too fast, and you risk overheating, poor chip formation, and premature tool wear.

A good starting range for a 1/8-inch carbide end mill in brass is typically between 8,000 and 15,000 RPM. The exact speed often depends on the rigidity of your machine, the depth of cut, and the specific alloy of brass.

Feed Rate (IPM or mm/min)

The feed rate is how fast the cutting tool is moved through the material. It’s crucial for chip thickness. You want to create chips that are thick enough to carry heat away and evacuate easily, but not so thick that they overload the tool or machine.

For a 1/8-inch 2-flute carbide end mill in brass, a common starting point for the feed rate can be anywhere from 15 to 40 inches per minute (IPM). Again, this is a guideline.

Understanding Chip Load: A more precise way to think about feed rate is “chip load,” which is the thickness of the chip produced by each cutting edge for each revolution of the tool. For a 1/8-inch tool in brass, a chip load of around 0.001 to 0.003 inches per flute is a good target. You can calculate your feed rate using the following formula:

Feed Rate (IPM) = Spindle Speed (RPM) × Number of Flutes × Chip Load (inches/flute)

Example Calculation:

Let’s say you are running your 1/8″ 2-flute carbide end mill at 10,000 RPM and want a chip load of 0.002 inches per flute:

Feed Rate = 10,000 RPM × 2 Flutes × 0.002 inches/flute = 40 IPM

Important Note: Always start at the lower end of the recommended speed and feed rates for your given parameters and gradually increase them if the cut is clean and chips are evacuating well. Listening to the machine and observing the chips is a machinist’s best tool for fine-tuning.

For reliable machining data and to learn more about spindle speeds and feed rates, consult resources like the Metalforming Magazine’s guide on calculating cutting speeds and feeds. Understanding the science behind these numbers helps ensure your success.

Depth of Cut and Stepover Strategies

How deep you cut and how much the tool advances sideways (stepover) also significantly impacts chip evacuation. For brittle materials, you might want deeper cuts. For gummy materials like brass, it’s often better to take shallower cuts combined with appropriate chip load and stepover.

Depth of Cut (DOC)

When milling brass with a small 1/8-inch end mill, aggressive depths of cut are generally not recommended, especially for the first pass or if chip evacuation is causing problems. Taking lighter cuts allows the tool flutes to clear chips more effectively.

General Recommendation: For a 1/8-inch end mill, a radial (sideways) depth of cut is often more critical than axial (downward) for chip evacuation in brass. A common axial depth of cut might be between 0.020″ and 0.060″ (0.5mm to 1.5mm). Always consider the flute length of your end mill; don’t cut deeper than the flutes extend.

Stepover

Stepover refers to the distance the tool moves sideways between passes when finishing a surface or pocketing. While a small stepover is perfect for achieving a smooth surface finish, it can sometimes lead to chip packing in the narrow flutes of a small end mill. For roughing or if you’re experiencing chip issues, slightly increasing the stepover can help by allowing more material to be removed in a single flute pass, thus creating larger chips.

Radial Stepover: For profiling or pocketing, a stepover of 40% to 70% of the tool diameter is common for roughing. For a 1/8″ (0.125″) end mill, this would be roughly 0.050″ to 0.0875″ (1.25mm to 2.2mm). A smaller stepover (e.g., 20-30%) will be needed for finer finishing passes.

Important Tip: If you’re pocketing a large area, consider using a larger milling tool for the bulk of the material removal and then “clean up” the corners and edges with your 1/8-inch end mill. This reduces the overall stress on the small tool.

Cooling and Lubrication: The Unsung Heroes

Even though brass is relatively soft, proper cooling and lubrication are still essential for effective chip evacuation and a clean cut. They help reduce friction, prevent chip welding, and carry chips away from the cutting zone.

Types of Coolant/Lubrication:

- Flood Coolant: A steady stream of coolant delivered directly to the cutting zone. This is highly effective for carrying chips away and keeping the tool cool.

- Mist Coolant: A fine spray of coolant. It’s less messy than flood but still provides good cooling and lubrication.

- Cutting Fluid/Oil: You can use specialized cutting fluids or even light machine oil on a clean cloth applied near the cut. Be mindful of flammability with some oils if your machine generates a lot of heat.

- Alcohol or WD-40: For very light cuts or hobbyist machines, isopropyl alcohol or WD-40 can sometimes provide just enough lubrication to help.

For Brass: A light, water-soluble cutting fluid is often ideal. It helps lubricate, keep the tool cool, and importantly, can help break the surface tension of the brass, allowing chips to be washed away more easily.

Don’t Forget Air Blast: Even without a liquid coolant system, a focused blast of compressed air directed at the cutting zone can significantly help blow chips away from the tool and workpiece. This is often a primary method for chip evacuation in gummy materials when liquid coolant isn’t an option.

Always ensure that whatever you use as a coolant or lubricant is appropriate for your machine and the material you are working with. Check your machine’s manual for compatibility.

Techniques for Enhanced Chip Evacuation

Beyond just setting parameters, there are several hands-on techniques you can employ to actively improve chip evacuation when milling brass with a 1/8-inch end mill.

- Peck Drilling/Plunging: If you need to make deep holes or pockets, use a “pecking” motion. This involves plunging the tool into the material for a short distance, retracting it to clear chips, and then plunging again. This is done incrementally until the desired depth is reached. Most CNC machining software (CAM) has a peck drilling cycle for this.

- Peck Machining: Similar to peck drilling, but applied to contouring or pocketing. The tool plunges, retracts slightly, moves forward a bit, then retracts to clear chips before continuing the pass.

- Climb Milling vs. Conventional Milling: For brass, climb milling is often preferred. In climb milling, the tool rotates in the same direction as it’s moving into the material. This produces a thinner chip at the start of the cut, which can help evacuation, and generally results in a better surface finish. Conventional milling, where the tool and workpiece move in opposite directions, tends to produce thicker chips that can be harder to clear.

- Back-Gashing/Chip Breaking: In manual machining, sometimes a slight “back-gash” or “chip breaker” groove on the edge of the tool or workpiece can help break the continuous chip into smaller, more manageable pieces. This is more advanced but effectively aids chip evacuation.

- Clearance Cuts: If you’re machining internal corners, ensure you’re using an end mill radius small enough for the corner or are planning for a clean-up pass. Sometimes, small radii can trap chips.

- “Blowing Out” Chips: Periodically stop the machine (if safe to do so) and use a brush or compressed air to clear chips from the flutes and from around the workpiece. This is especially important in manual machining or when a coolant system isn’t robust.

Troubleshooting Common Issues

Even with the best preparation, you might run into problems. Here’s how to troubleshoot common issues related to chip evacuation when milling brass.

Problem: Chips Welding to the End Mill

- Cause: Insufficient cooling, too high a spindle speed for the feed rate, or dull tool.

- Solution: Increase coolant or lubrication. Slow down spindle speed or increase feed rate slightly to achieve a better chip load. Ensure your end mill is sharp and free of built-up edge. Use climb milling.

Problem: Rough Surface Finish

- Cause: Clogged flutes, insufficient chip load (too fine a chip), chatter, or dull tool.

- Solution: Improve chip evacuation (check coolant, feed rate, and DOC). Increase chip load by increasing feed rate or slowing RPM if your DOC is constant. Ensure workpiece and tool are rigidly held. Verify tool sharpness.

Problem: End Mill Breaking

- Cause: Excessive depth of cut, too high feed rate, lack of lubrication, or entering the material too aggressively.

- Solution: Reduce depth of cut. Slow down feed rate. Ensure adequate cooling. Use a smoother entry into the material, potentially with a helical interpolation if your machine supports it for pockets.

Problem: Excessive Heat Build-up

- Cause: High spindle speed without enough cooling, too little chip load (rubbing instead of cutting), or clogged flutes holding heat in.

- Solution: Increase coolant flow. Adjust RPM/feed to create a proper chip load. Ensure flutes are clear. Use a tool with polished flutes.

Choosing the Right 1/8 Inch End Mill: A Comparison

Let’s look at the types of 1/8″ end mills and how they stack up for brass chip evacuation.

| End Mill Type | Best For Brass Chip Evacuation? | Pros | Cons |

|---|---|---|---|

| 2-Flute, Bright Finish, Standard Length | Good | Large flute gullets for chip clearance, polished surface reduces friction. | May flex more on deeper cuts than stub length. |

| 2-Flute, Bright Finish, Stub Length | Excellent | Excellent chip clearance, greater rigidity for robust cuts, less likely to deflect. Often specifically designed for softer metals. | Limited depth of cut due to shorter flute length. |

| 3-Flute, Bright Finish | Fair | Can provide a slightly better surface finish than 2-flute, but still manageable in brass with light cuts. | Reduced chip clearance can lead to packing in softer metals. |

| 4-Flute, Bright Finish | Poor | Best for finishing harder materials where chip packing isn’t an issue. | Smallest flute gullets, most prone to chip clogging in brass. |

| 1/8″ Shank with a larger diameter (e.g., 1/4″ or 1/2″ with a reduced shank) | Excellent | Combines the rigidity and chip-carrying capacity of a larger tool with the detail capability of a smaller cutting diameter. | Limited use for very small features. Shank diameter must be compatible with your collet/holder. Only applicable if you need to cut features larger than 1/8. |

For your specific goal, a “carbide end mill 1/8 inch 1