Quick Summary:

Minimize carbide end mill deflection by using shorter tools, increasing engagement, reducing chip load, matching speeds to material, and ensuring rigid setups. Proper technique prevents wavering cuts and improves finish quality for precise detailing.

Hey makers and aspiring machinists! Daniel Bates here from Lathe Hub. Ever notice your fine tool wandering off course when you’re trying to get a super clean cut, especially with those amazing carbide end mills? This “deflection” can be a real headache, turning precise lines into wobbly messes. It’s like your tool is trying to dance instead of cut! But don’t worry, this is a super common learning curve for all of us. With a few smart adjustments, you can get that straight, clean cut you’re after. Let’s dive into some genius tips to keep your carbide end mill on track and make your projects shine.

What Exactly is End Mill Deflection?

Simply put, end mill deflection is when your cutting tool bends or moves away from its intended path during the machining process. Think of it like a tiny diving board under stress. When the cutting forces are stronger than the tool’s stiffness, it bows. This bending causes your workpiece to be cut slightly larger than your programmed path, or with an uneven surface finish. It’s especially noticeable with smaller diameter tools, long reach tools, or when cutting tough materials.

Why You Need to Care About Deflection

Ignoring deflection can lead to a cascade of problems:

- Poor Accuracy: Your part won’t meet the required dimensions.

- Bad Surface Finish: You’ll get chatter marks, scallops, and an overall rough look.

- Tool Breakage: Excessive force from deflection can snap your end mill.

- Wasted Time and Material: You might have to scrap parts and start over.

For us beginners, mastering deflection means achieving those crisp, professional results we aim for.

Genius Tips to Minimize Carbide End Mill Deflection

Let’s get down to the good stuff. Here are proven strategies to keep your end mill cutting true:

Tip 1: Use the Shortest Possible Tool

This is probably the biggest factor in reducing deflection. The longer the flute length and the longer the tool sticks out of the collet or holder, the more leverage there is to bend it. Imagine a ruler: it’s much easier to bend a long ruler than a short one.

- Rule of Thumb: Try to keep the tool engagement (how far the tool sticks out of the holder) to a minimum, ideally no more than 3-4 times the tool’s diameter.

- Example: If you’re using a 1/4 inch (6mm) diameter end mill, try to keep the stick-out to around 1/2 inch (12mm) to 3/4 inch (18mm).

- For Long Reach Tools: If you must use a long reach tool (like a carbide end mill 3/16 inch 8mm shank long reach for acrylic that is designed for reaching deep into a part), be extra mindful of the other tips. These tools are inherently more prone to deflection.

Tip 2: Increase Tool Engagement (Depth of Cut)

This might seem counter-intuitive. Why engage the tool more? The idea here is to cut deeper but take narrower “bites.” Instead of taking many shallow passes, take fewer, deeper passes. This reduces the number of times the tool has to flex and put stress on the system. However, this is a delicate balance, as too deep a cut can cause deflection too. It’s about optimizing the ratio.

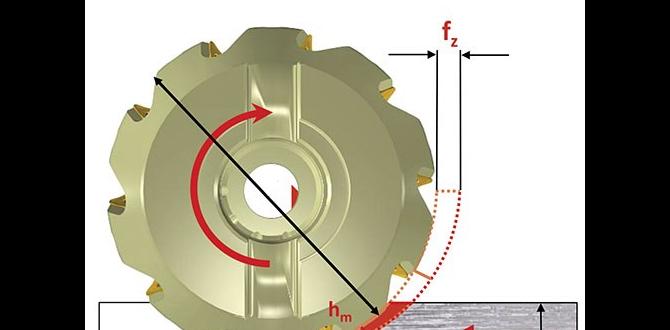

- Radial vs. Axial Depth of Cut: Think about how much of the tool’s diameter is cutting (radial) versus how deep into the material it’s going (axial).

- Milling Strategy Matters: For minimizing deflection, you want to control how the tool engages the material. Techniques like high-efficiency milling (HEM) or trochoidal milling can help by keeping a consistent chip load and reducing the tendency for the tool to dig in erratically.

- Control Your Cuts: If you’re slotting (cutting a full-width groove), you’ll experience more deflection than when “pocketing” (cutting a smaller area within a larger piece).

Tip 3: Reduce Chip Load and Feed Rate

Chip load is the thickness of the material each cutting edge of the end mill removes with each revolution. A heavier chip load means more material being pushed away, which increases cutting forces and deflection. A lighter chip load puts less strain on the tool.

- What to Adjust: You can reduce chip load by lowering your feed rate (how fast the tool moves into the material) or by using fewer flutes on your end mill if your machine allows for spindle speed changes.

- Feed Rate Calculation: A common formula for feed rate (in inches per minute) is: Feed Rate = (Chip Load) x (Number of Flutes) x (Spindle Speed in RPM).

- Experiment: Start with conservative settings and gradually increase the feed rate until you hear the tool start to chatter or see deflection. Then back off slightly. Use resources like Machining Doctor or manufacturer’s recommendation charts for starting points.

Tip 4: Optimize Spindle Speed and Cutting Strategy

The speed at which your end mill spins also plays a crucial role. Too fast, and you can overheat the tool or material. Too slow, and you might not be cutting efficiently, leading to rubbing and increased forces. Matching your spindle speed to your material and tool is key.

- Surface Speed: This is the speed at which the cutting edge of the tool is moving across the material. Different materials require different surface speeds for optimal cutting. For example, aluminum generally benefits from higher surface speeds than steel.

- Carbide is Different: Carbide end mills can handle higher speeds and temperatures than High-Speed Steel (HSS) tools, but they are also more brittle.

- Cutting Strategies:

- Climb Milling: In climb milling, the tool rotates in the same direction as the feed movement. This tends to produce a better surface finish and can reduce the tendency for the tool to wander, as the chip is being thinned as it’s cut.

- Conventional Milling: Here, the tool rotates against the feed direction. It can sometimes lead to increased deflection because the tool has to “climb over” the material.

Tip 5: Ensure Rigidity in Your Setup

Any movement or “play” in your machine, workholding, or tool holding will add to deflection. A solid setup is the foundation for precise cuts.

- Machine Rigidity: Make sure your milling machine is in good condition. Loose ways, worn spindle bearings, or a wobbly Z-axis can all contribute to deflection.

- Workholding: Clamp your workpiece securely. Using vises, clamps, or fixtures that don’t move during the cut is critical. Avoid using only posts or simple clamps if possible when high forces are involved.

- Tool Holder: Use a high-quality collet chuck or tool holder. A worn or loose collet can allow the end mill to shift, introducing runout and increasing deflection. Shrink fit holders offer the best rigidity.

- Balancing: For very high-speed machining, balanced tool holders are essential to prevent vibration.

Tip 6: Use Appropriate and Sharp Tools

The carbide end mill itself matters. Using the right type and ensuring it’s sharp makes a huge difference.

- Number of Flutes:

- 2 or 3 Flutes: Generally preferred for milling softer materials like aluminum and plastics, and often for slotting. They provide better chip clearance.

- 4 Flutes: Good for harder materials and finishing passes, as they offer more rigidity and a smoother surface finish, but can have poorer chip evacuation.

- Tool Material: Carbide is great because it’s hard and can cut faster, but it’s brittle. For woodworking or very soft plastics, a specialized plastic-cutting end mill or even a bit designed for the material might be better than standard carbide to avoid melting or gumming. For metals, carbide is your friend!

- Sharpness: A dull end mill requires more force to cut, leading to increased deflection. Always use sharp tools. If you’re unsure, assume it’s dull and consider sharpening or replacing it.

Advanced Techniques for Challenging Materials

When cutting tricky materials, especially with tools like a carbide end mill 3/16 inch 8mm shank long reach for acrylic, you might need to finesse your approach even more.

Micropolishing and Coatings

Some specialized end mills come with polished flutes or advanced coatings (like TiAlN or DLC). These reduce friction, improve chip flow, and help prevent material from sticking to the tool, all of which can indirectly reduce cutting forces and deflection.

Variable Helix and Pitch

Tools with a variable helix angle (the angle of the cutting edge spiraling around the tool) or variable pitch (the distance between flutes) are designed to break up harmonic vibrations. These vibrations are a major cause of chatter and can exacerbate deflection. If you’re battling chatter, a variable helix/pitch end mill can be a game-changer.

Multi-Flute Strategies for Plastics (like Acrylic)

When working with materials like acrylic, you want to remove material quickly and efficiently to prevent melting and gumming up. Despite this, deflection is still a concern. Using a high-quality, sharp end mill designed for plastics (often with very few flutes, like 1 or 2, and a polished edge) is usually best. For your specific query about a carbide end mill 3/16 inch 8mm shank long reach for acrylic, ensure it’s cut with a geometry suitable for plastics. A very sharp, single-flute or two-flute end mill with a high rake angle is often ideal. Control your feed rate carefully to avoid melting, and if using a longer tool, really lean on the rigidity tips!

Troubleshooting Deflection: Common Scenarios

Let’s look at some common problems and how to fix them:

| Problem | Likely Cause | Solution |

|---|---|---|

| Wobbly cuts or poor surface finish. | Tool deflection. | Shorten tool stick-out, reduce feed rate, increase depth of cut (appropriately), use a more rigid holder, ensure workholding is secure. |

| Tool vibrating or chattering excessively. | Resonance, dull tool, improper chip load. | Try a variable helix end mill, ensure tool is sharp, adjust feed rate/spindle speed, try different depth of cut (axial/radial), ensure machine rigidity. |

| Part is cut oversize. | Tool deflection bending away from the workpiece. | Reduce cutting forces: take lighter cuts, slower feed rate, shallower depth of cut. Ensure spindle speed is appropriate for the material. |

| Tool breaking when plunging or entering cut. | Too much engagement force, dull tool, improper plunge strategy. | Use a specialized plunge end mill, back off feed rate on entry, ensure tool is sharp and appropriate for the material. For plastics, avoid plunging directly if possible; use a ramping motion. |

Carbide End Mill Specs and Deflection

When you look at buying an end mill, especially for a specific job like milling acrylic, the specs are important:

- Diameter: Smaller diameters (like 3/16 inch or 8mm) are more prone to deflection than larger ones.

- Shank Size: A larger shank diameter (like 8mm) will be more rigid than a smaller one (like 3/16 inch, if the shank is also that size). An 8mm shank is generally more rigid than a 1/4 inch (approx 6.35mm) shank.

- Length of Cut (LOC) / Flute Length: A longer LOC means a longer tool, increasing deflection potential.

- Overall Length (OAL): The total length of the tool. A shorter OAL means less stick-out.

- Number of Flutes: As discussed, 2/3 flutes for chip clearing, 4+ for finishing.

- Helix Angle: Standard is usually 30 degrees. Higher (45 or 60) can sometimes help with chatter. Variable helix is specialized.

For that carbide end mill 3/16 inch 8mm shank long reach for acrylic, the “long reach” aspect is your primary challenge for deflection. This often means you’ll need to compensate with shallower depths of cut and slower feed rates than you might with a shorter tool.

Safety First, Always!

Machining can be dangerous if not done with care. Always wear safety glasses, ensure your workpiece is securely clamped, and never reach near moving machinery. If you’re unsure about a setting, err on the side of caution. If a tool starts chattering or acting strange, stop the machine immediately and investigate. A moment of caution can prevent injury or damage.

FAQ About Carbide End Mill Deflection

What is the ideal stick-out for a Carbide End Mill?

For most situations, aim for a stick-out of no more than 3 to 4 times the diameter of the end mill. For example, if you’re using a 1/4 inch (6mm) end mill, try to keep it sticking out of the collet by no more than 3/4 inch to 1 inch (18mm to 25mm).

Can I use a longer tool to reach deeper if I just go slower?

Going slower (reducing feed rate) helps, but it doesn’t eliminate the fundamental issue of tool leverage. A longer tool still has more tendency to bend. You’ll need to combine a slower feed rate with shallower depths of cut and ensure your setup is as rigid as possible when using long-reach tools.

How many flutes should my carbide end mill have to minimize deflection?

Generally, for minimizing deflection, using an end mill with fewer flutes (2 or 3) can be beneficial. This allows for larger chip gullets to evacuate material more easily, reducing the forces on the tool. However, 4-flute end mills are often more rigid themselves and better for finishing passes where chatter is less of an issue.

I am cutting acrylic and my end mill is deflecting. What do I do?

Acrylic can be tricky. Use a sharp, specialized plastic-cutting end mill (often 1 or 2 flutes with a polished edge). Ensure it’s designed for plastics to prevent melting. Reduce your depth of cut significantly and find a feed rate that clears chips without melting. For a long-reach tool on acrylic, this means very shallow cuts and a controlled approach to avoid deflection and melting.